Mulberry picking machine

A technology for picking machines and mulberries, which is applied to picking machines, harvesters, agricultural machinery and tools, etc. It can solve the problems of unhygienic, time-consuming and labor-intensive picking, and slow speed, so as to reduce labor costs, meet picking needs, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

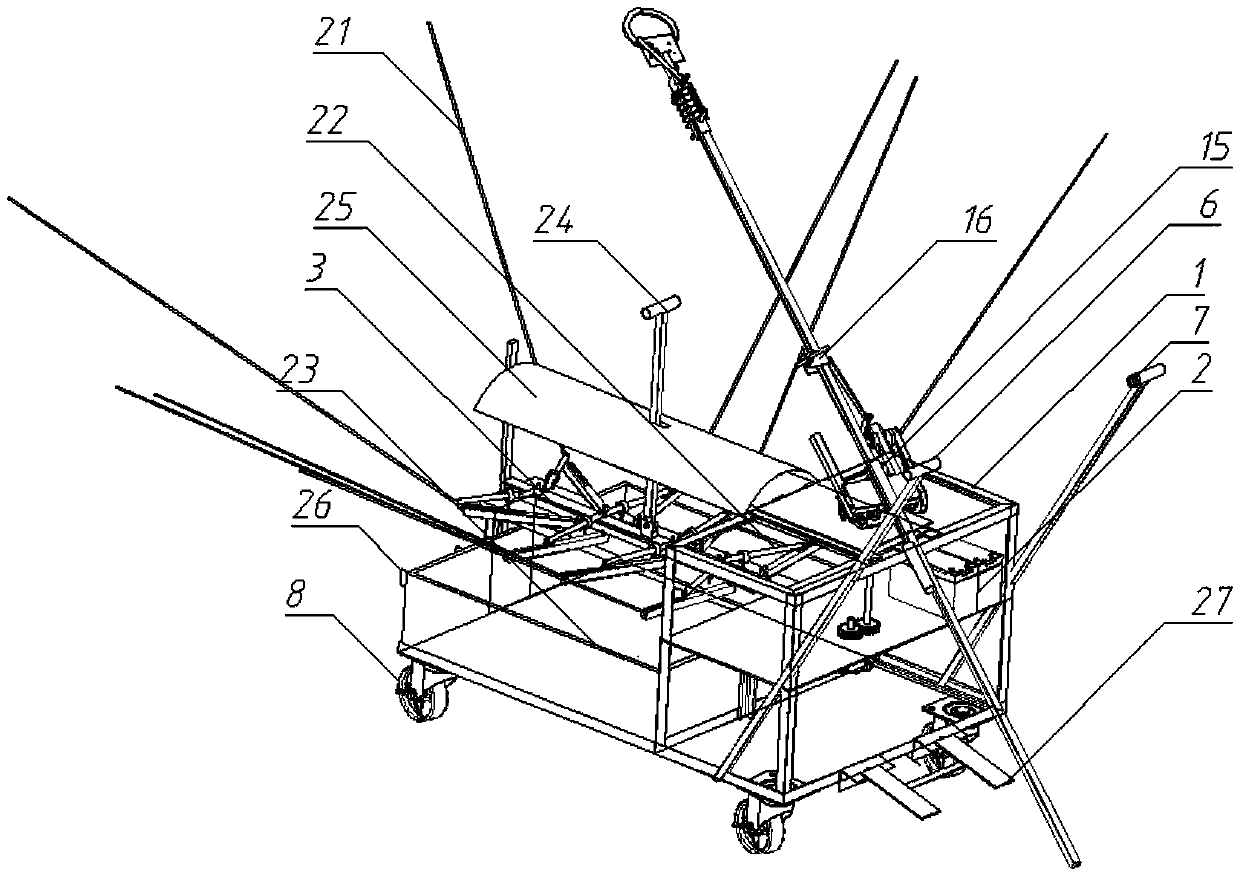

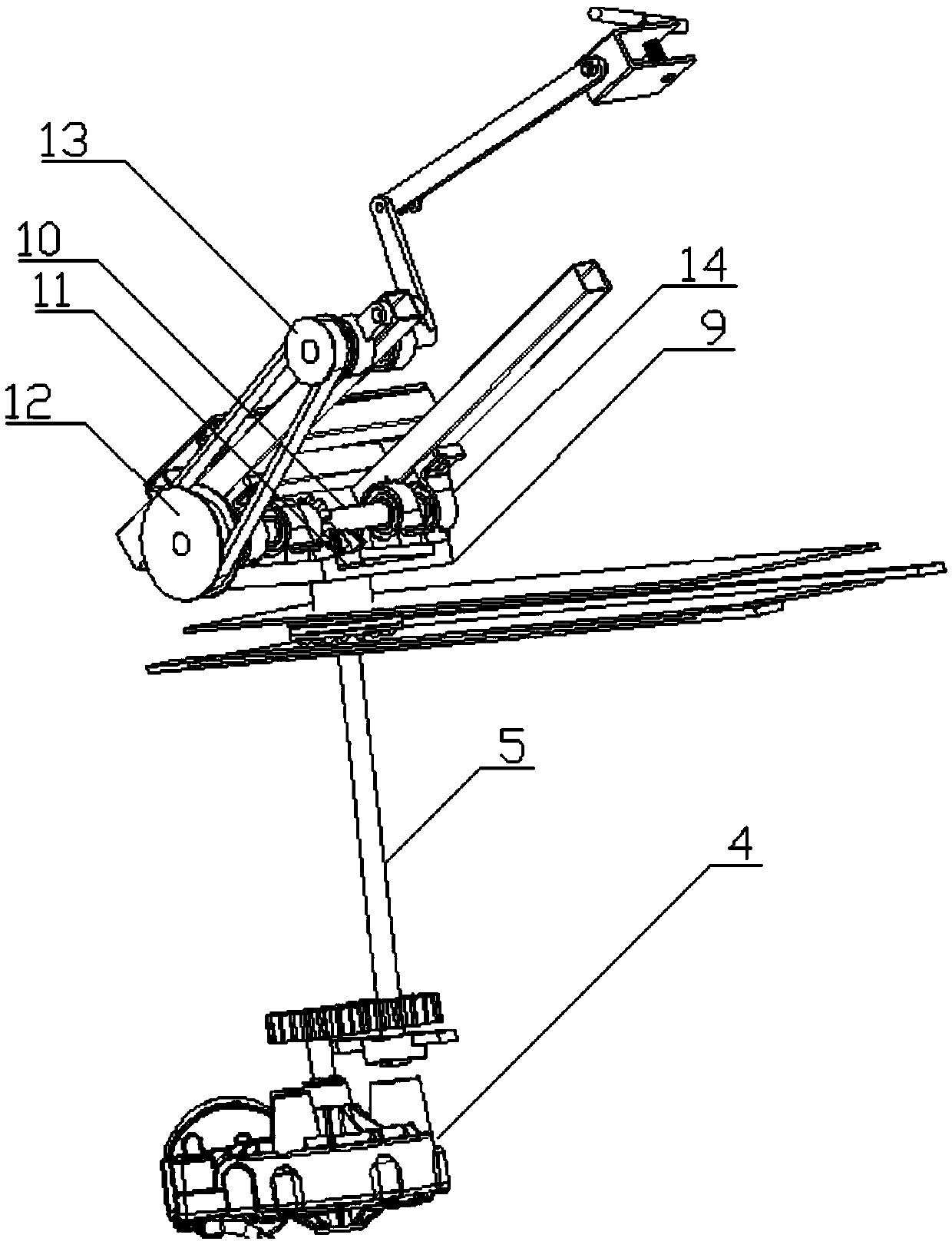

[0030] Such as figure 1 As shown, the main structure of the present invention includes a frame 1, a transmission mechanism, a grabbing mechanism, a collecting mechanism and a stabilizing mechanism. Frame 1 is used as the bearing and connection of the mechanism. The front part of the main body is equipped with two layers of collecting mechanism, and the middle part is three layers. 4. The power output shaft 5 of the motor 4 is connected upwards to the transmission mechanism, and the transmission mechanism is connected to the grabbing mechanism. The rear part is the handle of the rack 6. The power switch and the governor knob 7 are used to control the speed of the shaking tree. The bottom is Four universal wheels 8 are so as to adjust direction when turning around the trunk, and the two parts of the head and the tail are combined to form a stabilizing me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com