Desulfurization reagent for removing pyrrhotite in iron concentrate containing high sulphur by flotation method

A technology of high pyrite concentrate and pyrrhotite is applied in the field of beneficiation activator and flotation to remove pyrrhotite in high pyrite concentrate, which can solve the problem of low recovery rate and high iron concentrate recovery rate. Problems such as poor desulfurization effect of pyrite concentrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

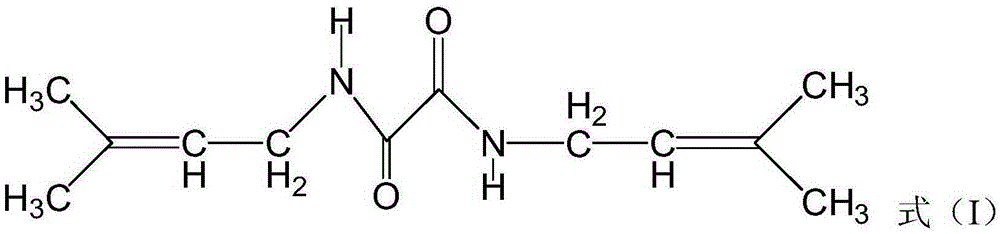

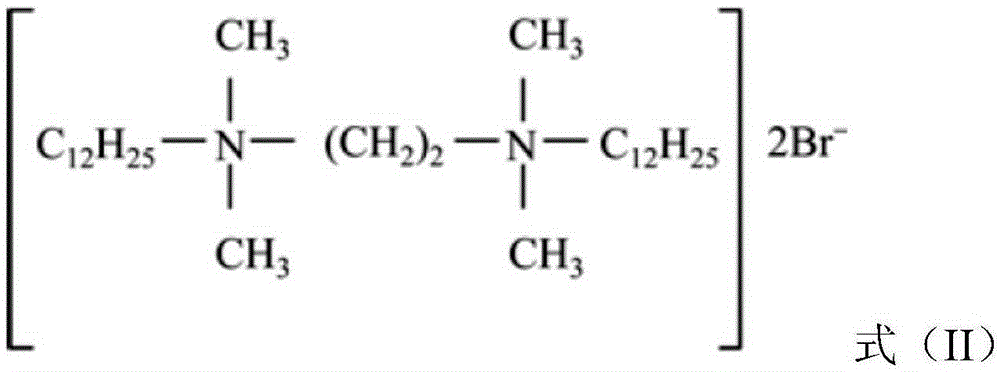

Method used

Image

Examples

Embodiment 1

[0042] A high-sulfur magnetic separation iron concentrate containing sulfur mainly pyrrhotite in Inner Mongolia has an iron grade of 68.70% and a sulfur grade of 1.66%. The flotation process of "one rough, one fine, two sweep" is used for flotation desulfurization. The flotation reagents were added sequentially in the order of LJ reagent, collector butyl xanthate, and foamer No. 2 oil, and the dosage of the reagents in the selection and sweeping sections was halved at one time. The reagent system is shown in Tables 1 and 2.

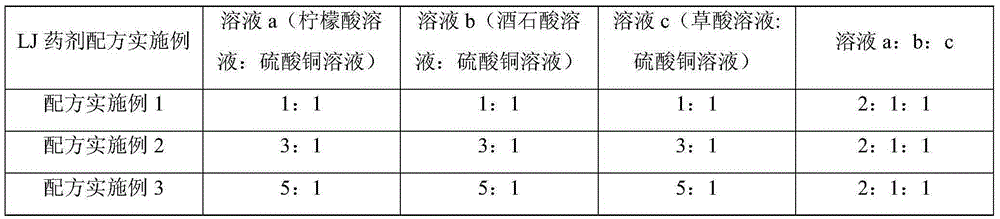

[0043] Table 1 Flotation LJ agent formula (solution mass percent concentration is 1%, all mixed by mass ratio)

[0044]

[0045] Table 2 Flotation LJ reagent dosage (g / t, calculated according to the weight of dry ore for flotation)

[0046]

[0047] For the above flotation process, the control flotation time is 3-10 minutes for the rough selection section, 2-8 minutes for the fine selection section, 2-6 minutes for the first section of sweeping, and...

Embodiment 2

[0052] A high-sulfur magnetic separation iron concentrate containing sulfur mainly pyrrhotite in Inner Mongolia has an iron grade of 66.70% and a sulfur grade of 2.34%. The flotation process of "one rough, one fine, two sweep" is used for flotation desulfurization. The flotation reagents were added sequentially in the order of LJ reagent, collector butyl xanthate, and foamer No. 2 oil, and the dose of reagents in the selection and sweeping sections was halved once. The reagent system is shown in Tables 4 and 5.

[0053] Table 4 flotation LJ medicament formula (solution mass percent concentration is 1%, all mixed by mass ratio)

[0054]

[0055] Table 5 Flotation LJ reagent dosage (g / t, calculated according to the weight of dry ore feed to ore for flotation)

[0056]

[0057] For the above flotation process, the control flotation time is 3-10 minutes for the rough selection section, 2-8 minutes for the fine selection section, 2-6 minutes for the first section of sweeping,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com