Flotation process for open-air low-grade copper ore

A low-grade, flotation technology, used in flotation, solid separation and other directions, can solve the problems of refractory copper ore, large power consumption, and many sets of equipment, and achieves improved copper concentrate grade, improved copper recovery, Good production indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

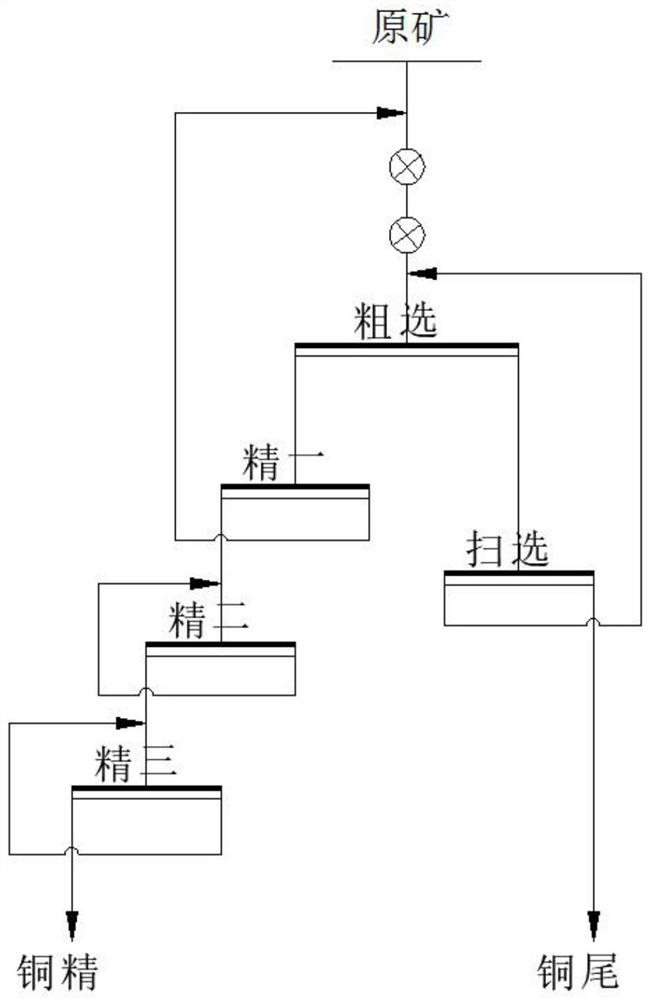

Image

Examples

Embodiment 1

[0032] The copper ore with a grade of 0.3% in the third processing plant of Dahongshan is selected for flotation. First, the raw ore is crushed to a particle size of -250mm, and then subjected to a first-stage semi-autogenous grinding and a first-stage ball milling to obtain a concentration of 42% and a particle size of -200%. 80% ore pulp, add 10g / t butylamine black medicine, 50g / t butyl xanthate and 30g / t terpineol oil successively, stir, and the ore pulp after adding and stirring enters three KYF-200 flotation columns for coarsening. Selection operation, flotation for 7 minutes, to obtain rougher concentrate and rougher tailings. The rougher tailings enter 3 sets of KYF-200 flotation columns for scavenging flotation operation (the amount of sodium butyl xanthate added is 45g / t, the amount of butylamine black medicine is 6g / t, and the amount of terpineol oil is added The amount of scavenging concentrate is 6g / t), the scavenging concentrate is obtained, the scavenging concent...

Embodiment 2

[0034] The copper ore with a grade of 0.13% in the third processing plant of Dahongshan is selected for flotation. First, the raw ore is crushed to a particle size of -250mm, and then subjected to a first-stage semi-autogenous grinding and a first-stage ball milling to obtain a concentration of 40% and a particle size of -200%. 75% of the pulp, add 8g / t butylamine black medicine, 45g / t butyl xanthate and 25g / t terpineol oil successively, stir, and the pulp after adding and stirring enters two KYF-200 flotation columns for coarsening. Selection operation, flotation for 7 minutes, to obtain rougher concentrate and rougher tailings. The rougher tailings enter 2 sets of KYF-200 flotation columns for scavenging flotation operation (the amount of butyl sodium xanthate added is 40g / t, the amount of butylamine black medicine is 5g / t, and the amount of terpineol oil is added The amount of scavenging concentrate is 5g / t), and the scavenging concentrate is obtained, and the scavenging co...

Embodiment 3

[0036] The copper ore with a grade of 0.17% in Dahongshan No. 3 processing plant is selected for flotation. First, the raw ore is crushed to a particle size of -250mm, and then subjected to a first-stage semi-autogenous grinding and a first-stage ball milling to obtain a concentration of 41% and a particle size of -200%. 78% of the pulp, add 6g / t butylamine black medicine, 40g / t butyl xanthate and 20g / t terpineol oil successively, stir, and the pulp after adding and stirring enters three KYF-200 flotation columns for coarsening. Selection operation, flotation for 7 minutes, to obtain rougher concentrate and rougher tailings. The rougher tailings enter 3 sets of KYF-200 flotation columns for sweep flotation operation (the amount of sodium butyl xanthate added is 35g / t, the amount of butylamine nigrosine is 4g / t, and the amount of terpineol oil is added The amount of scavenging concentrate is 4g / t), and the scavenging concentrate is obtained, and the scavenging concentrate is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com