A push transfer device for a sandbox trolley

A push device and sand box technology, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of oil leakage in the cooling section, strong labor intensity, dirty and messy, etc., and achieves easy cleaning, high pushing precision and good buffering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

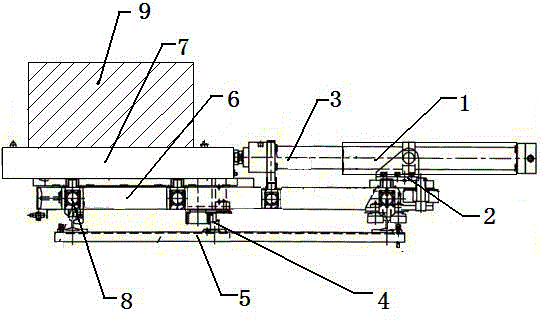

[0011] This embodiment provides a pushing device for a sandbox trolley, which is characterized in that: the pushing device for a sandbox trolley includes a telescopic hydraulic cylinder (1), a fixed base (2), a hydraulic cylinder piston (3) , pillar (4), frame (5), slideway (6), sliding trolley (7), slider (8), sand box (9);

[0012] Among them: the lowermost end of the device is provided with a frame (5) with a slideway (6), and a sliding trolley (7) and a telescopic hydraulic cylinder (1) are arranged on the chassis (5), and the sliding trolley (7) There are two sliders (8) below, which can slide on the slideway (6). Three pillars (4) are arranged between the slideway (6) and the frame (5). The telescopic hydraulic cylinder (1) cylinder body There is a fixed base (2) between the slideway (6), and the front end of the hydraulic cylinder piston (3) of the telescopic hydraulic cylinder (1) is provided with a slide block (8) that slides with the slideway (6). The front end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com