Paper transferring and suction air path structure and operating method thereof

A technology of suction air path and working method, which is applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problems of poor reliability, large hose wear, and cumbersome problems, and achieve high reliability and durability, and simple structure , reduce the effect of support points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

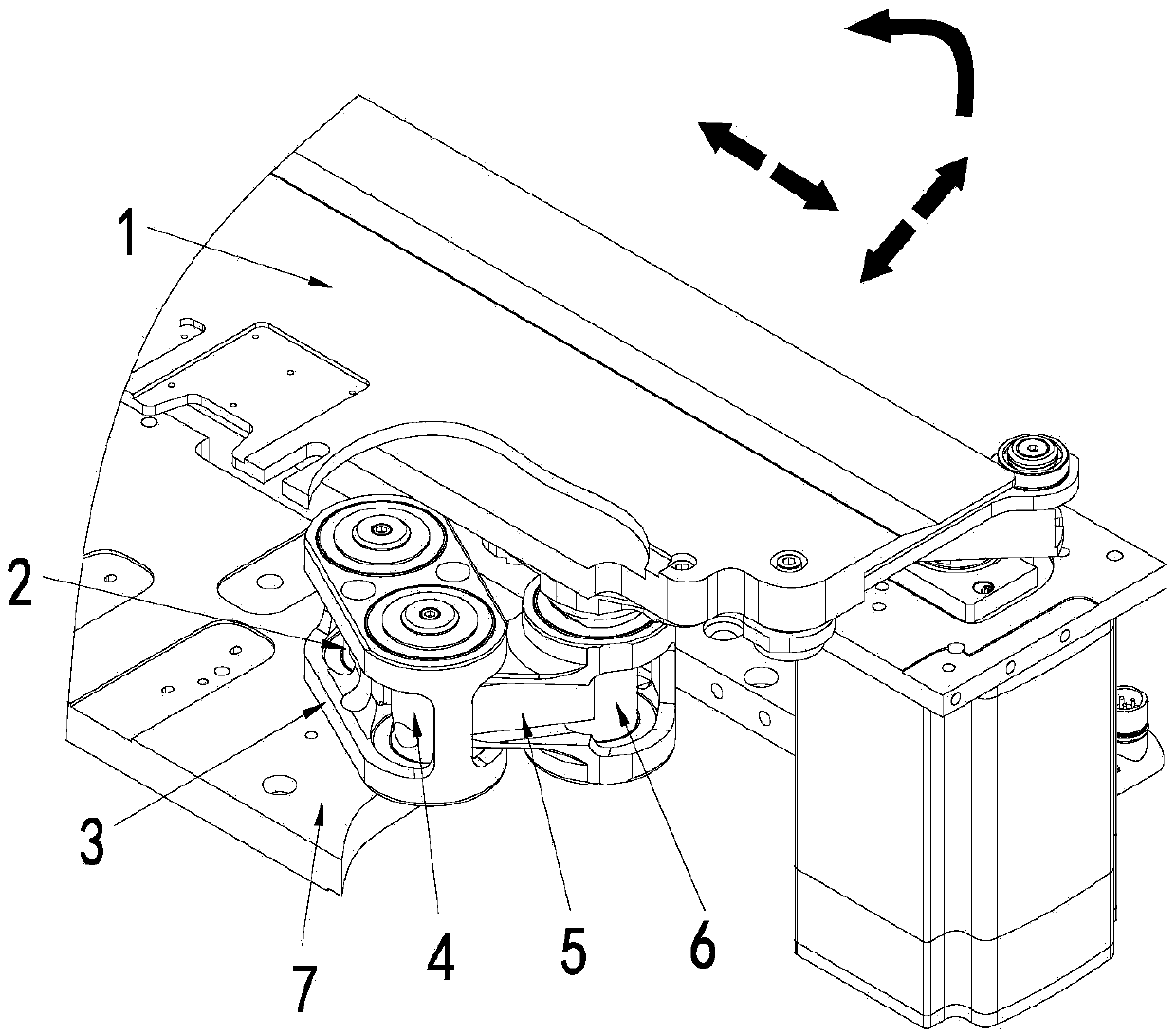

[0015] Embodiment: a kind of paper-passing suction air path structure (see figure 1 ), which is characterized in that it includes a paper passer plate 1, a connecting rod support mechanism and a bottom plate 7; the two ends of the link support mechanism are respectively hinged with the paper passer plate 1 and the bottom plate 7; the paper passer plate 1, The connecting rod support mechanism and the bottom plate 7 are provided with vent holes communicating with each other.

[0016] The connecting rod support mechanism includes a fixed mandrel I2, a connecting rod I3, a movable mandrel 4, a connecting rod II5 and a fixed mandrel II6; the fixed mandrel I2 is fixed on the bottom plate 7; The paper board 1 is fixedly connected; one end of the connecting rod I3 forms a rotatable hinge with the fixed mandrel I2 through a pair of bearings, and the other end of the connecting rod I3 forms a rotatable hinge with the movable mandrel 4 through a bearing; the connecting rod II5 One end i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com