Ramming clamp and method for cooling wall expansion gap

A stave and expansion joint technology, applied in the direction of cooling devices, etc., can solve the problems of reducing the life of the blast furnace hearth, affecting the service life of the blast furnace hearth, and affecting the cooling intensity, so as to avoid gas blowing in the stave, improve the ramming method, The effect of guaranteeing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings of the embodiments.

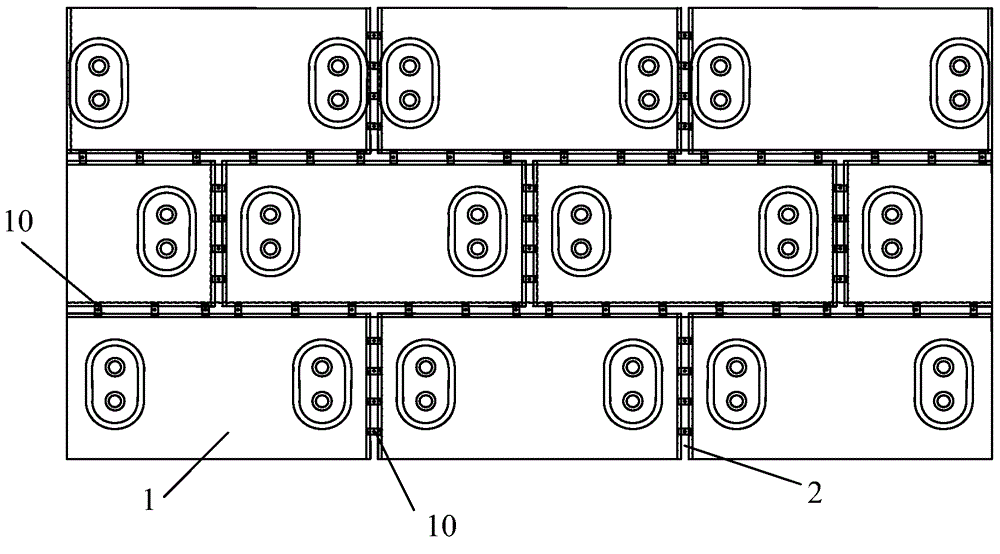

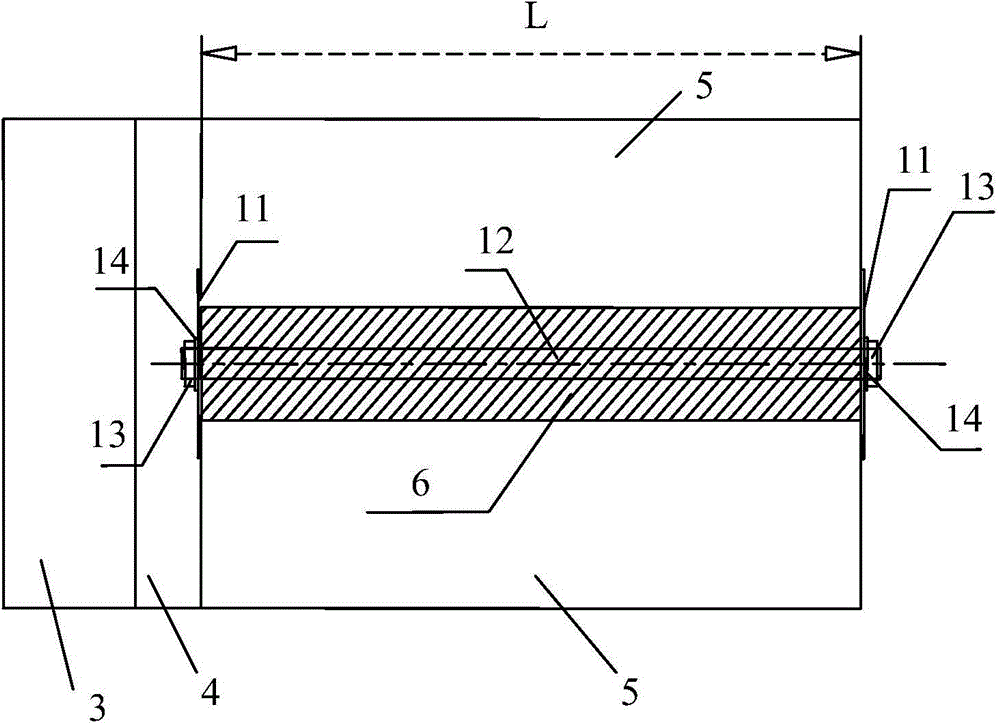

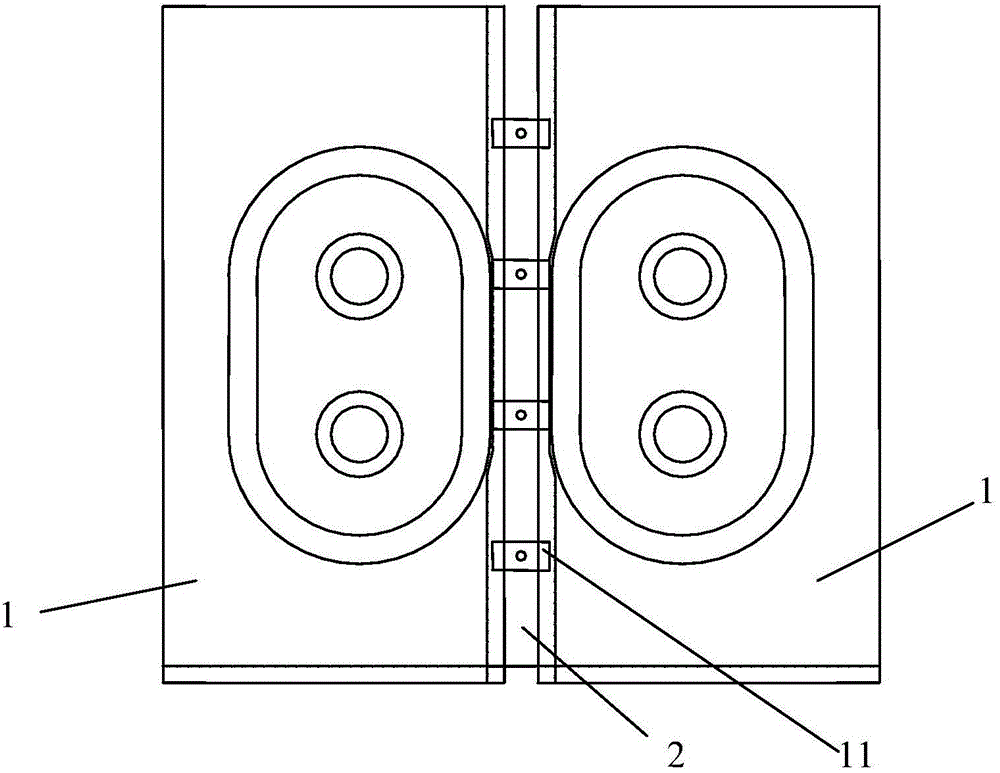

[0032] see figure 1 and figure 2 , the stave expansion joint ramming fixture 100 of the present invention is respectively arranged at intervals in the expansion joints 2 between the horizontal and vertical adjacent staves 1, and each ramming fixture includes a pair of steel baffle plates 11, a screw rod 12. A pair of fastening nuts 13, the length of the two baffles 11 is greater than the width of the expansion joint 2, and they are respectively located outside the two ends of the expansion joint 2, and overlapped with the outer walls of the two adjacent staves 1, the baffles 11 There are also screw holes on the top, the two ends of the screw rod 12 pass through the expansion joint 2 along the length direction of the expansion joint 2, and respectively pass through the screw holes of the baffle plate 11, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com