Cleaning drum for electroplating of automobile parts

A technology for auto parts and cleaning cylinders, which is applied in the direction of electrolysis components, electrolysis process, cells, etc. It can solve the problems of insufficient cleaning power and inability to clean auto parts evenly, and achieve the effect of good stirring power and improved cleaning power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

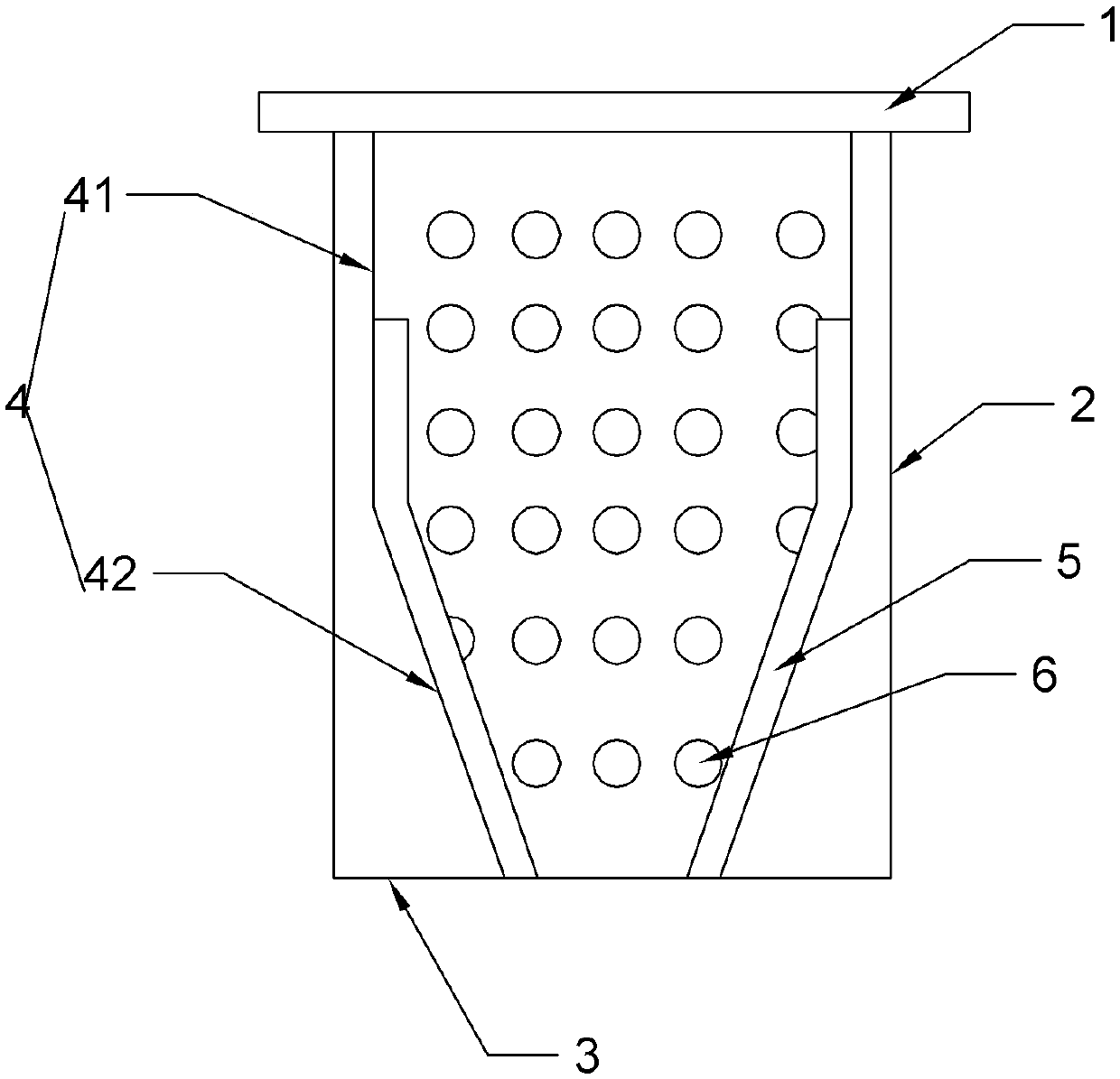

[0015] The marks in the accompanying drawings of the present invention are: protrusion 1, side wall 2, bottom plate 3, inner shell 4, upper half section 41, lower half section 42, stirring bar 5.

[0016] Such as figure 1 As shown, the cleaning cylinder for electroplating auto parts includes a cleaning cylinder body, the cleaning cylinder body is a cylindrical structure without a cover, the upper end of the cleaning cylinder body is provided with a protrusion 1 along the circumference, and the lower end surface of the protrusion 1 is a hollow structure. It is easy for the manipulator to grasp. The cleaning cylinder body includes a side wall 2 and a bottom plate 3. Water outlet holes 4 are provided on the side wall 2 and the bottom plate 3. A layer of inner shell 4 is set inside the side wall 2. A channel corresponding to the direction of the water outlet holes 6 is arranged on the inner shell 4. The water hole, the inner shell 4 is made of plastic material. The inner shell 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com