Calculating method for maximal lifting height of viscous debris flow and application of calculating method

A debris flow and viscous technology, used in hydraulic engineering, marine engineering, construction, etc., can solve problems such as damage, low accuracy of calculated values, and instability of sand dams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

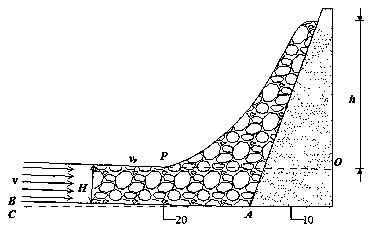

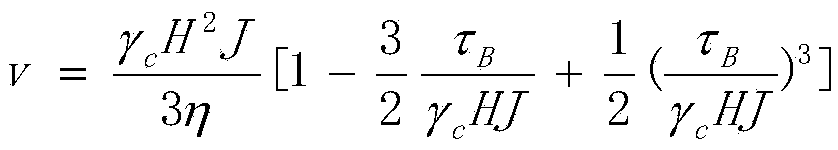

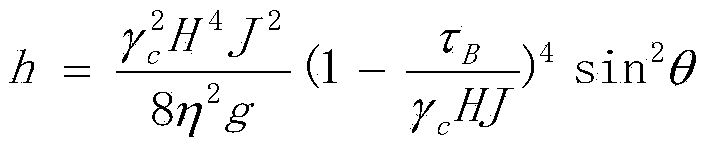

[0059] A debris flow ditch is a medium-sized debris flow ditch with an altitude of 1920m to 3500m and a drainage area of 12.2km 2 . There have been many mudslides in the ditch, which seriously threatened the safety of local people's lives and property. In order to reduce debris flow disasters, it is planned to build a sand retaining dam project in the debris flow migration area. The following is the design of the safe height of the debris flow of the sand control dam, and the steps are as follows:

[0060] (1) Through large-scale topographic map measurement and calculation, it is determined that the average vertical gradient J of the debris flow channel is 0.10, and the angle θ between the movement direction of the debris flow and the sand bar is 120°.

[0061] (2) Determine the bulk density of debris flow through actual sampling measurement γ c 22kN / m 3 .

[0062] (3) Through actual investigation and calculation, the design flow Q of debris flow is 200m 3 / s;

[0063...

Embodiment 2

[0069] A debris flow ditch is a very active viscous debris flow ditch. The drainage area of the ditch is 3.7km 2 , the main ditch is 2.5km long, the highest point elevation of the basin is 3061m, and the lowest point elevation is 2400m. Frequent mudslides occurred in the ditch, posing a serious threat to local traffic, industrial and agricultural production, and village safety. In order to reduce debris flow disasters and ensure the production and life of the people in the villages and towns on the right side of the ditch bank, it is planned to build a 500m protection embankment at the intersection of the ditch and the main river. To design the safe height of the debris flow of the debris flow protection embankment, the steps are as follows:

[0070] (1) Through the measurement and calculation of the large-scale topographic map, it is determined that the average vertical gradient J of the debris flow channel is 0.06, and the angle θ between the movement direction of the de...

Embodiment 3

[0079] The drainage area of a debris flow ditch is 0.66km 2 , the length of the main ditch is 2.20km. The ditch has the terrain, loose material and water source conditions for debris flow outbreaks. It is a disastrous old debris flow ditch. There have been many mudslides in history, causing serious damage to the roads and houses at the mouth of the ditch. In order to reduce the debris flow disaster, it is planned to build a drainage channel project in the debris flow accumulation area. The following is the design of the safe height value considering the maximum height of the debris flow at the bend of the guide trough, and the steps are as follows:

[0080] (1) Through on-site investigation and measurement, it is determined that the average vertical gradient J of the debris flow drainage channel is 0.08, and the angle θ between the same row of guide channels in the direction of debris flow movement at the bend is 150°.

[0081] (2) Through actual sampling and measurement, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com