Piezoelectric pump

A piezoelectric pump and piezoelectric vibrator technology, which can be used in pumps, pumps with flexible working elements, and liquid variable-capacity machines, etc., can solve the problems of complex valve assembly, high assembly precision requirements, and inconvenience in mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

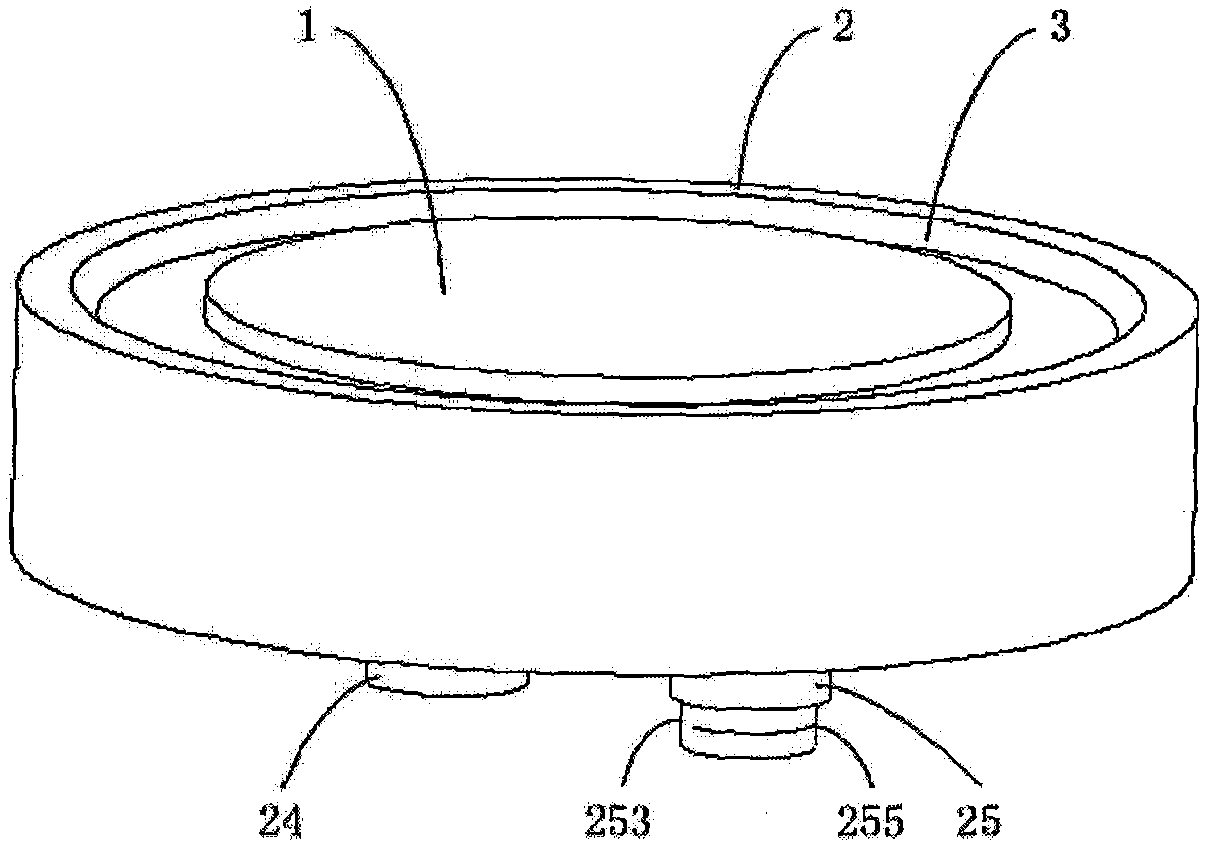

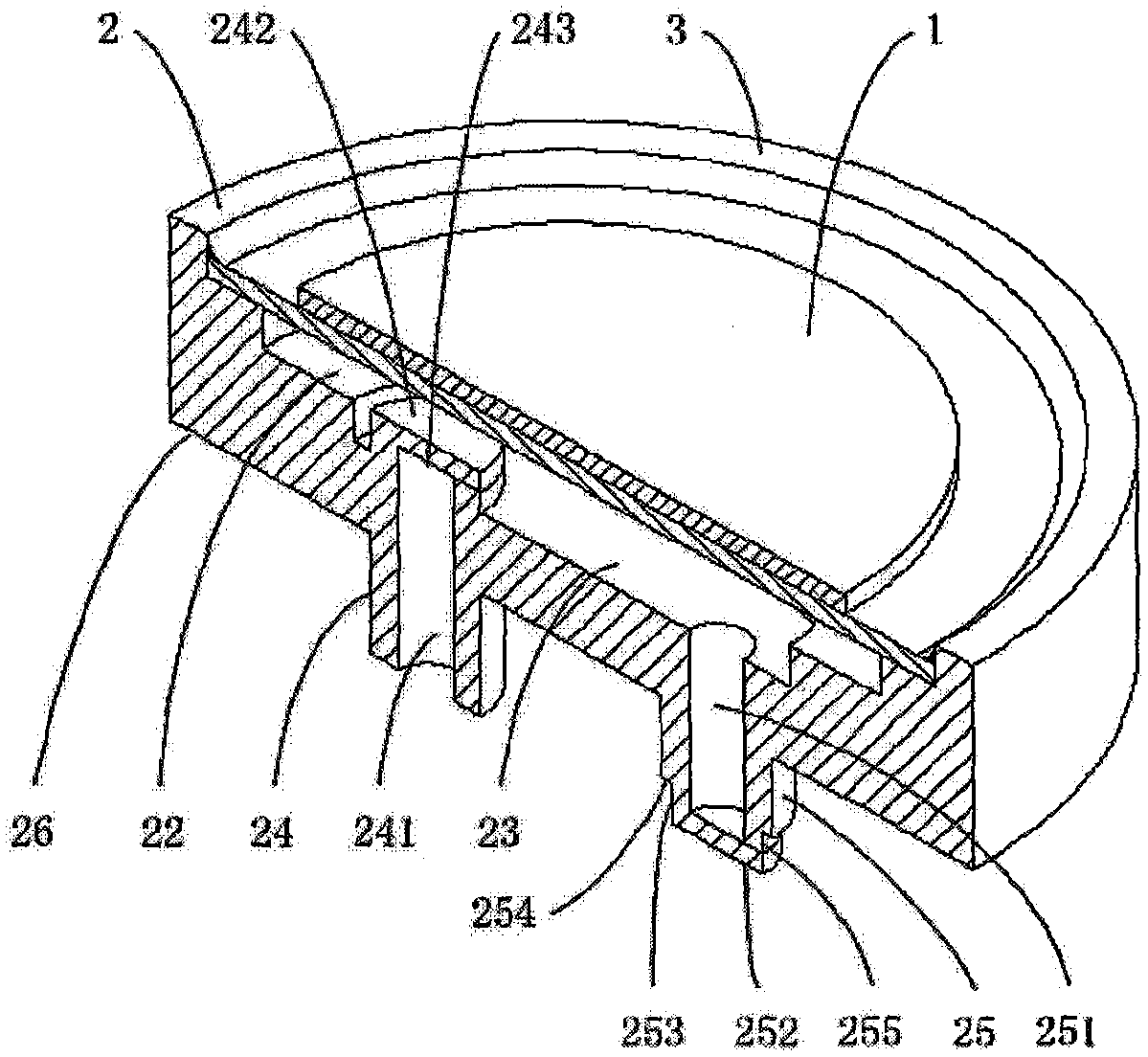

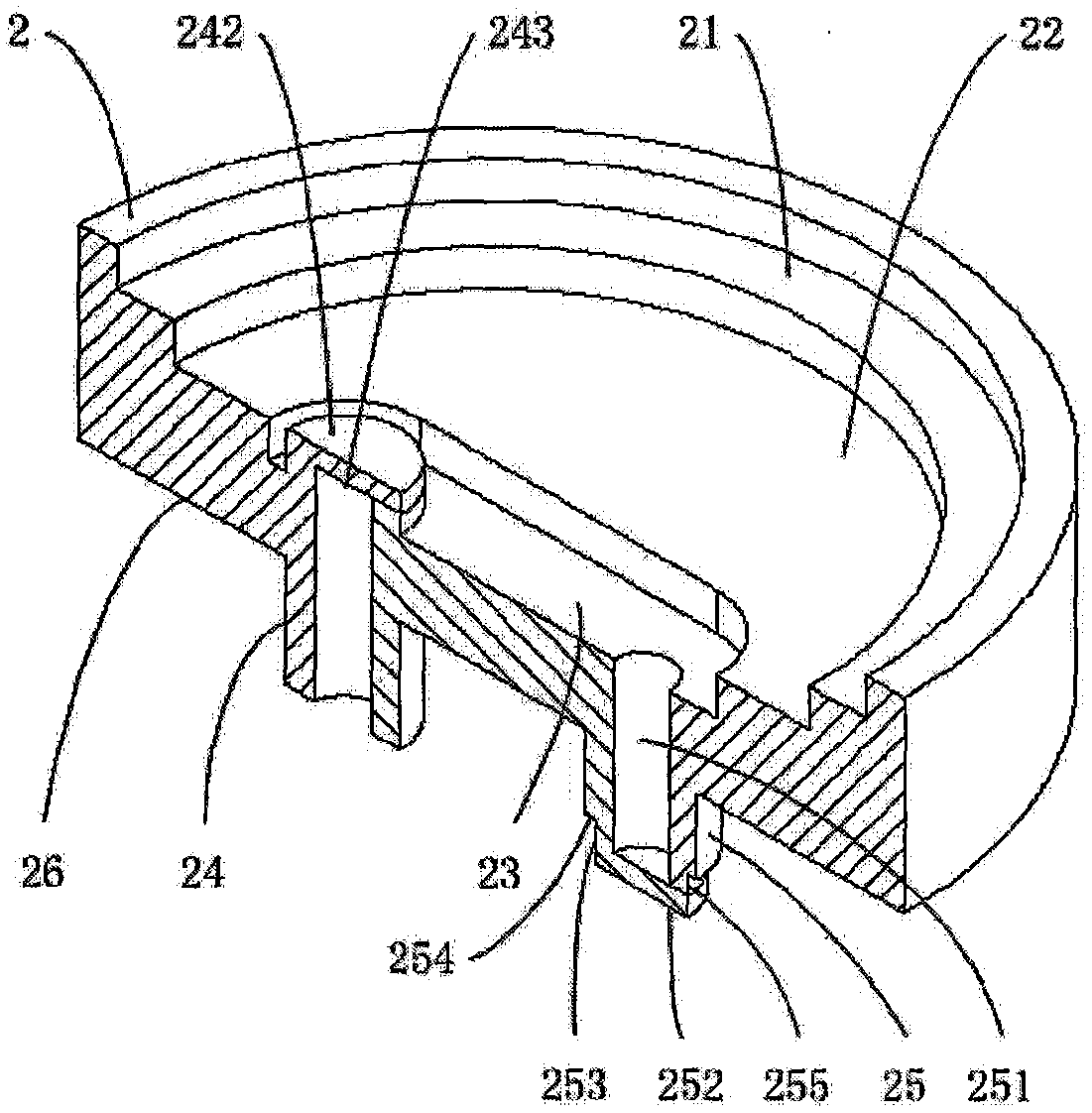

[0012] refer to figure 1 , the piezoelectric pump of the present invention is composed of a piezoelectric vibrator 1 and an integral cavity valve part 2, wherein:

[0013] The piezoelectric vibrator 1 is installed on one side of the integrated cavity valve part 2; the integrated cavity valve part 2 is made of a rubber material or rubber and plastic materials, and the vibrator installation groove is arranged on the integrated cavity valve part 21. The piezoelectric vibrator 1 is installed in the vibrator installation groove 21, and a cavity sinker 22 is arranged in the center of the vibrator installation groove 21. After the piezoelectric vibrator 1 is installed, the cavity sinker 22 forms a sealed cavity, that is, a pump cavity. A diversion groove 23 is arranged at the bottom of the cavity sinker 22, and the inlet 24 and outlet 25 of the cavity are arranged at the bottom of the diversion groove 23; the inlet 24 is a cylindrical structure with an inlet sink hole 241 inside, arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com