A piston transmission mechanism and a two-dimensional compressor

A compressor and piston shaft technology, applied in the field of compressors, can solve the problems of difficulty in reaching, large leakage, and high rotation speed of screw compressors, and achieve the effects of reducing production costs, reducing frictional resistance, and increasing working speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

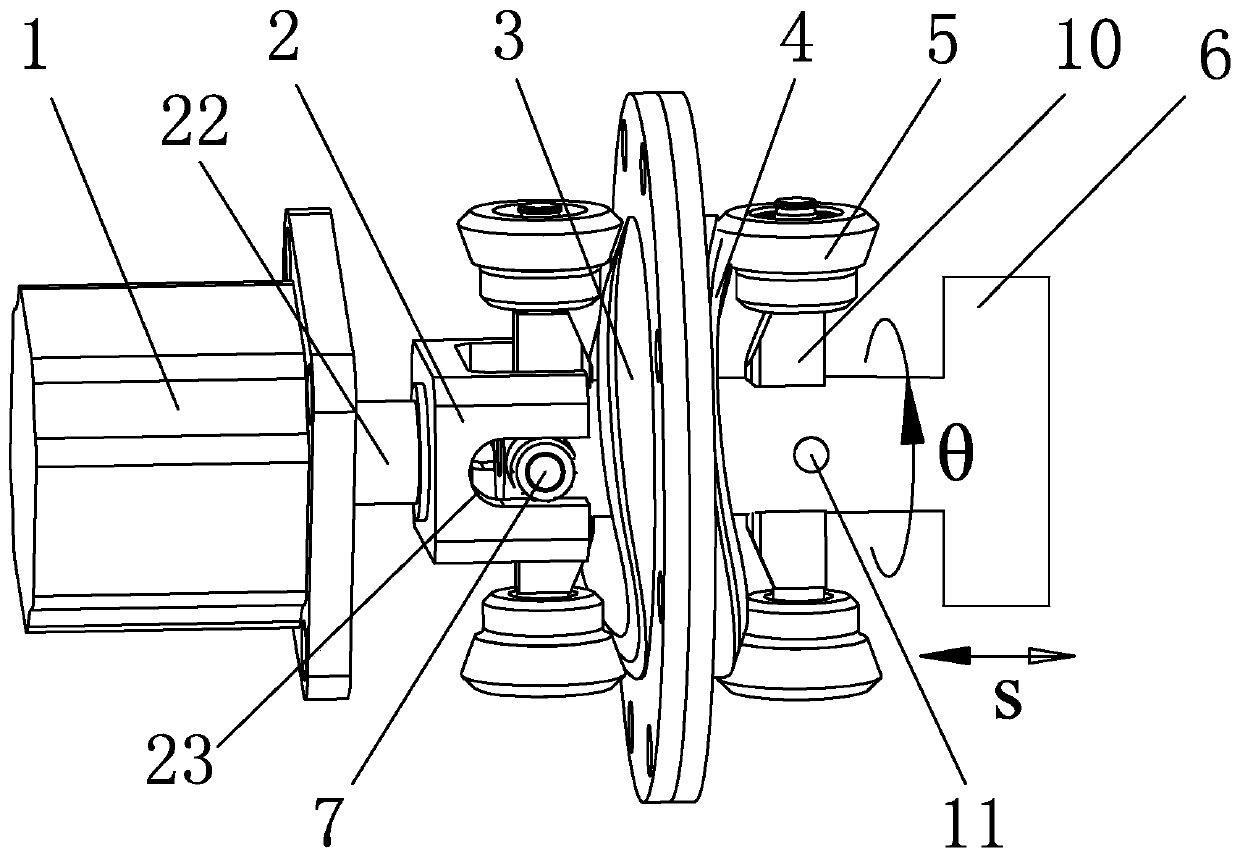

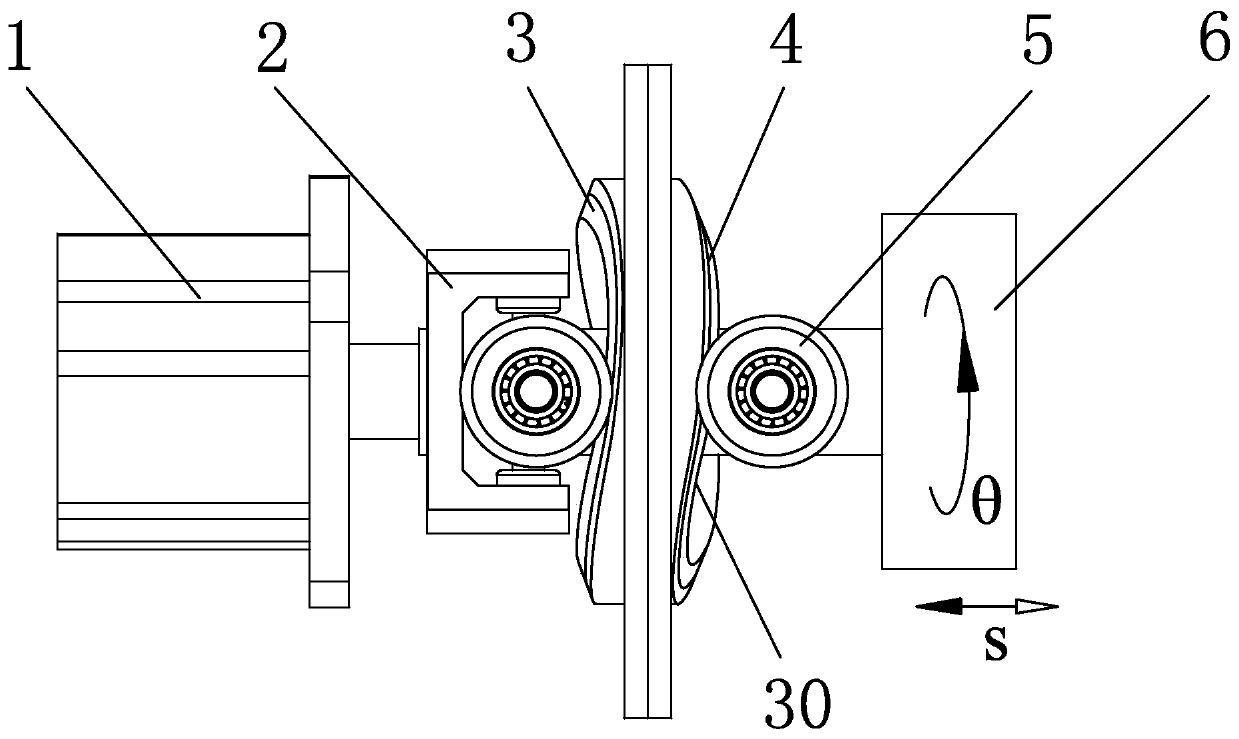

[0051] like Figure 1 to Figure 4 As shown, a piston transmission mechanism includes a motor 1 and a piston shaft 6. The motor 1 has an output shaft 22, and the output shaft 22 is fixedly provided with a shaft coupling 2 that rotates synchronously with it. 22 is provided with a side groove 23 in the axial direction, and a pin shaft 7 is fixedly arranged on the outside of the piston shaft 6, and a needle bearing 12 is installed inside the pin shaft 7, and the needle roller bearing 12 is limited to the side groove 23 and forms a sliding motion with the side groove 23. Cooperate;

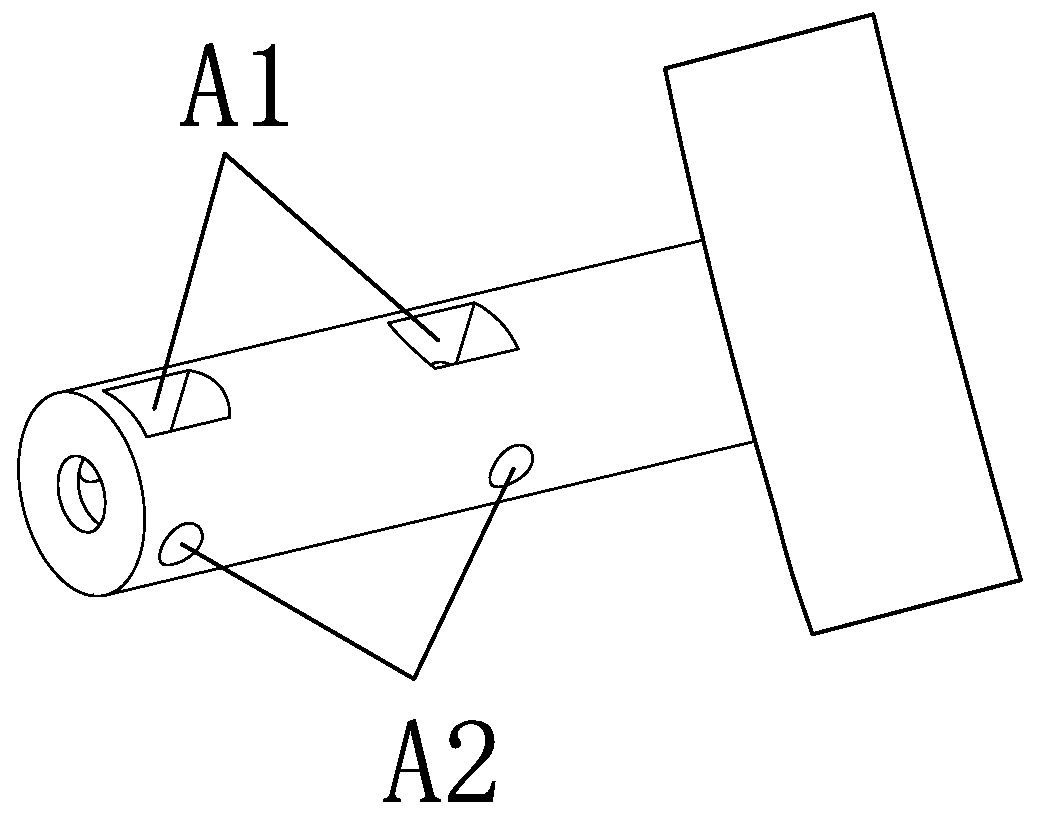

[0052] The piston shaft 6 is sequentially provided with two rotating shaft holes A1 arranged at intervals, and each rotating shaft hole A1 is respectively inserted with a rotating shaft 10 limited in its own rotating shaft hole A1, and the position of the piston shaft 6 corresponding to each rotating shaft hole A1 is provided with a pin hole A2, Each pin hole A2 is inserted with a fastening pin 11 to ...

Embodiment 2

[0055] A two-dimensional piston compressor composed of a piston transmission mechanism described in Embodiment 1, the two-dimensional piston compressor includes a single-stage two-dimensional piston compressor, a two-stage two-dimensional piston compressor and a three-stage two-dimensional piston compressor. dimensional piston compressor.

[0056] like Figure 5 to Figure 9 As shown, Embodiment 2 is a single-stage two-dimensional piston compressor, including a single-stage cylinder 15 fixedly connected to a piston transmission mechanism, and the piston shaft 6 is a single-stage piston shaft 14 .

[0057] like Figure 5 and Image 6 As shown, the shaft of the single-stage piston shaft 14 is provided with a rotating shaft hole A1 and a pin hole A2, and the piston of the single-stage piston shaft 14 is provided with radially symmetrically distributed single-stage piston grooves A3; Figure 7 As shown, the single-stage cylinder 15 is provided with radially symmetrically distrib...

Embodiment 3

[0061] like Figure 10 to Figure 15 As shown, Embodiment 3 is a two-stage two-dimensional piston compressor, including a two-stage cylinder 17 , which is fixedly connected with the piston transmission mechanism, and the piston shaft 6 is the two-stage piston shaft 16 .

[0062] like Figure 10 and Figure 11 As shown, the shaft of the secondary piston shaft 16 is provided with a rotating shaft hole A1 and a pin hole A2, and the piston of the secondary piston shaft 16 is provided with a radially symmetrical secondary piston groove A4; as Figure 12 and Figure 13 As shown, the secondary cylinder block 17 is provided with a radially symmetrically distributed secondary compression outlet O3 and a secondary compressed air inlet O4, and the inner wall of the secondary cylinder block 17 is provided with a radially symmetrically distributed secondary cylinder The first-stage exhaust groove B1 of the body and the second-stage exhaust groove B2 of the secondary cylinder block; the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com