Axial plunger pump

A technology of axial piston pump and plunger, which is applied in the direction of pumps, multi-cylinder pumps, liquid displacement machinery, etc., can solve the limitation of the PV allowable value of the friction pair of the distribution plate, the difficulty of realizing large displacement and high pressure pumps, Problems such as mechanical vibration cannot be eliminated, so as to achieve the effect of improving service life, reducing radial size and eliminating interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

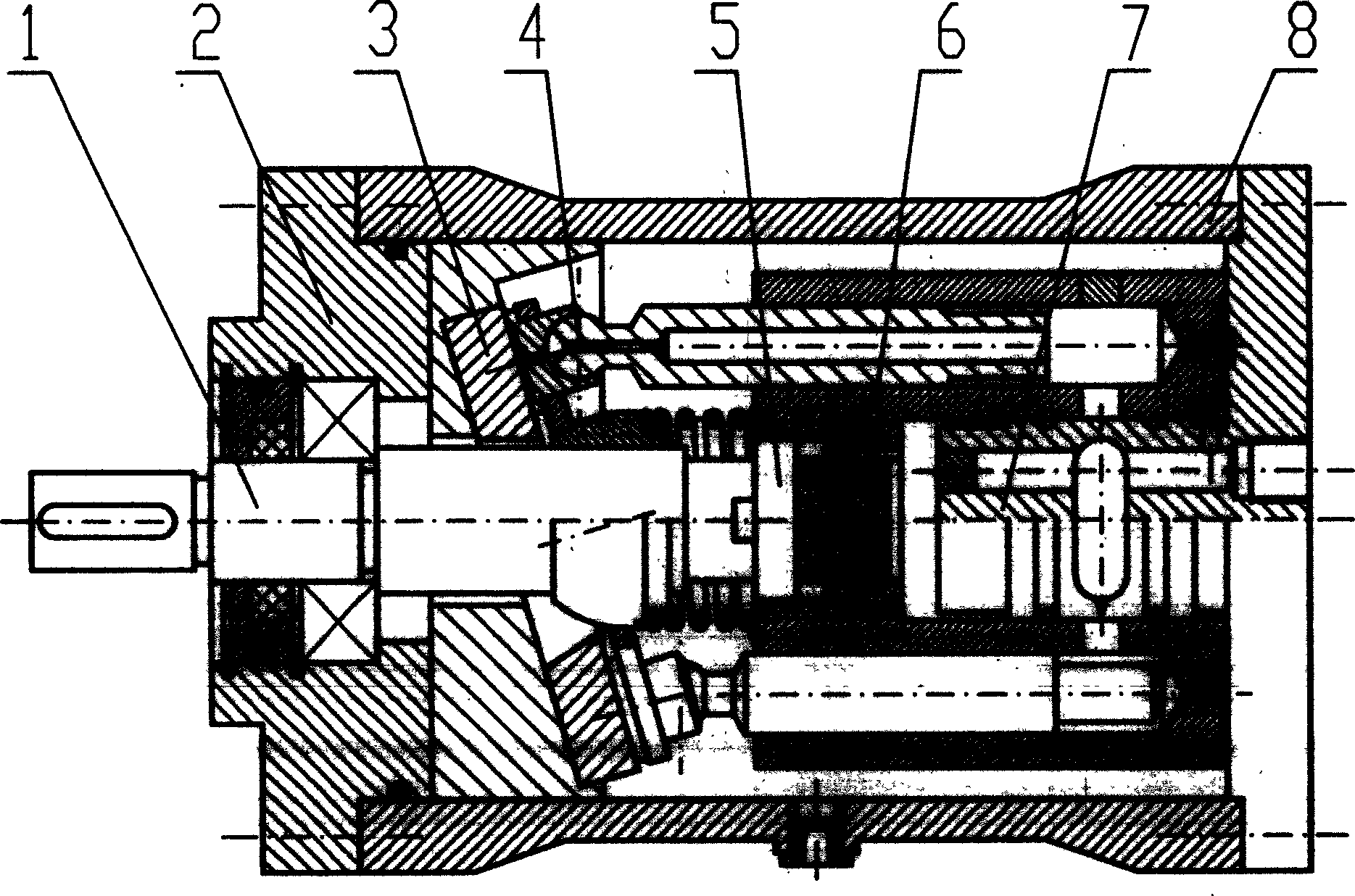

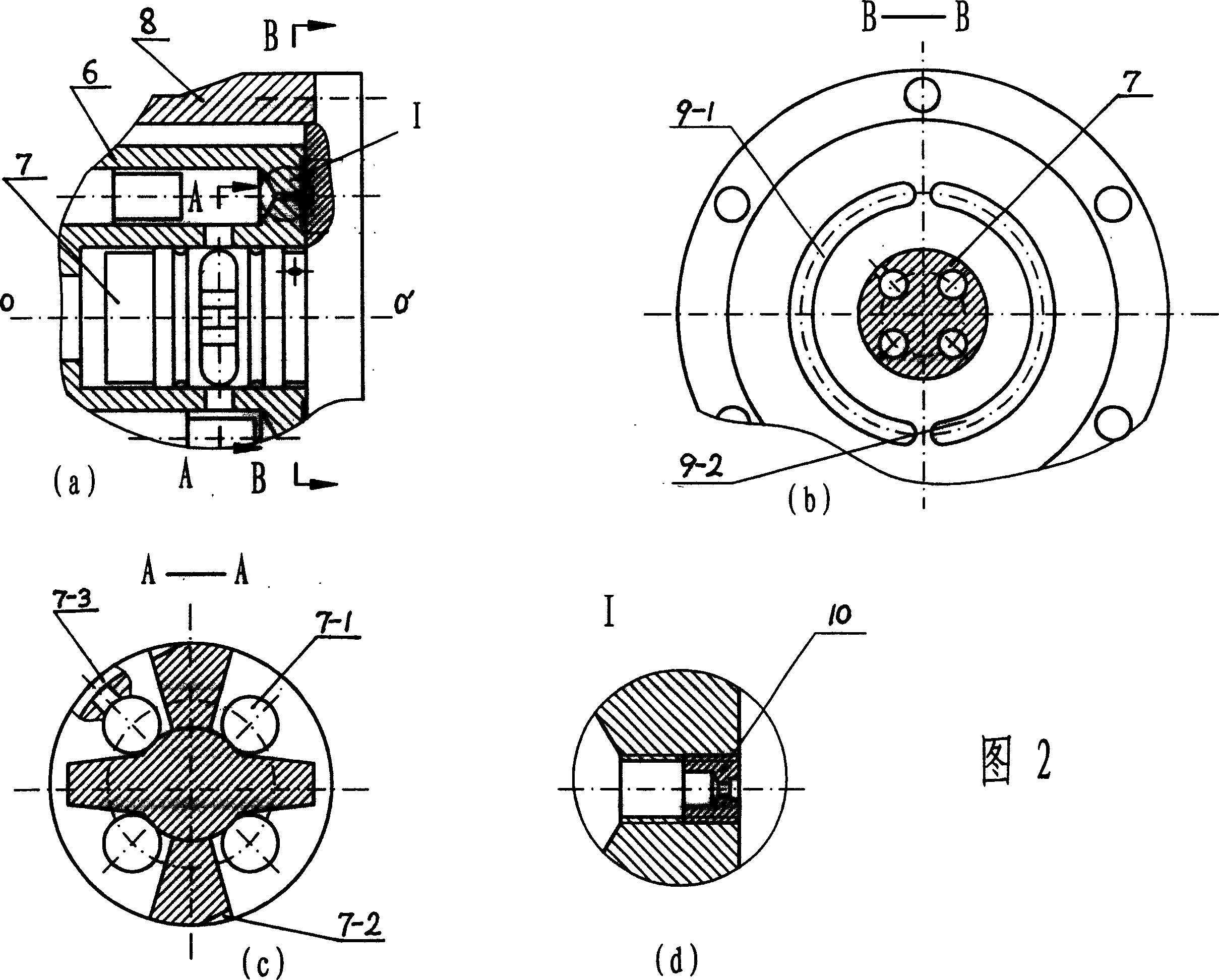

[0018] Such as figure 1 As shown, the present invention comprises main transmission shaft (1), pump body (8), end cover (2), distribution shaft (7), swash plate (3), cylinder body (6), and cylinder body (6) is installed in Inside the pump body (8), the sliding shoe plunger group (4) is placed in the cylinder body (6) and extended to support the swash plate (3), the sliding shoe plunger group (4) and the main drive shaft (1) The docked cross slider group (5) together forms a rotating part, and the flow distribution shaft (7) is placed in the cylinder body (6). The main transmission shaft (1) drives the cross slider group (5) to rotate under the drive of the motor or the like.

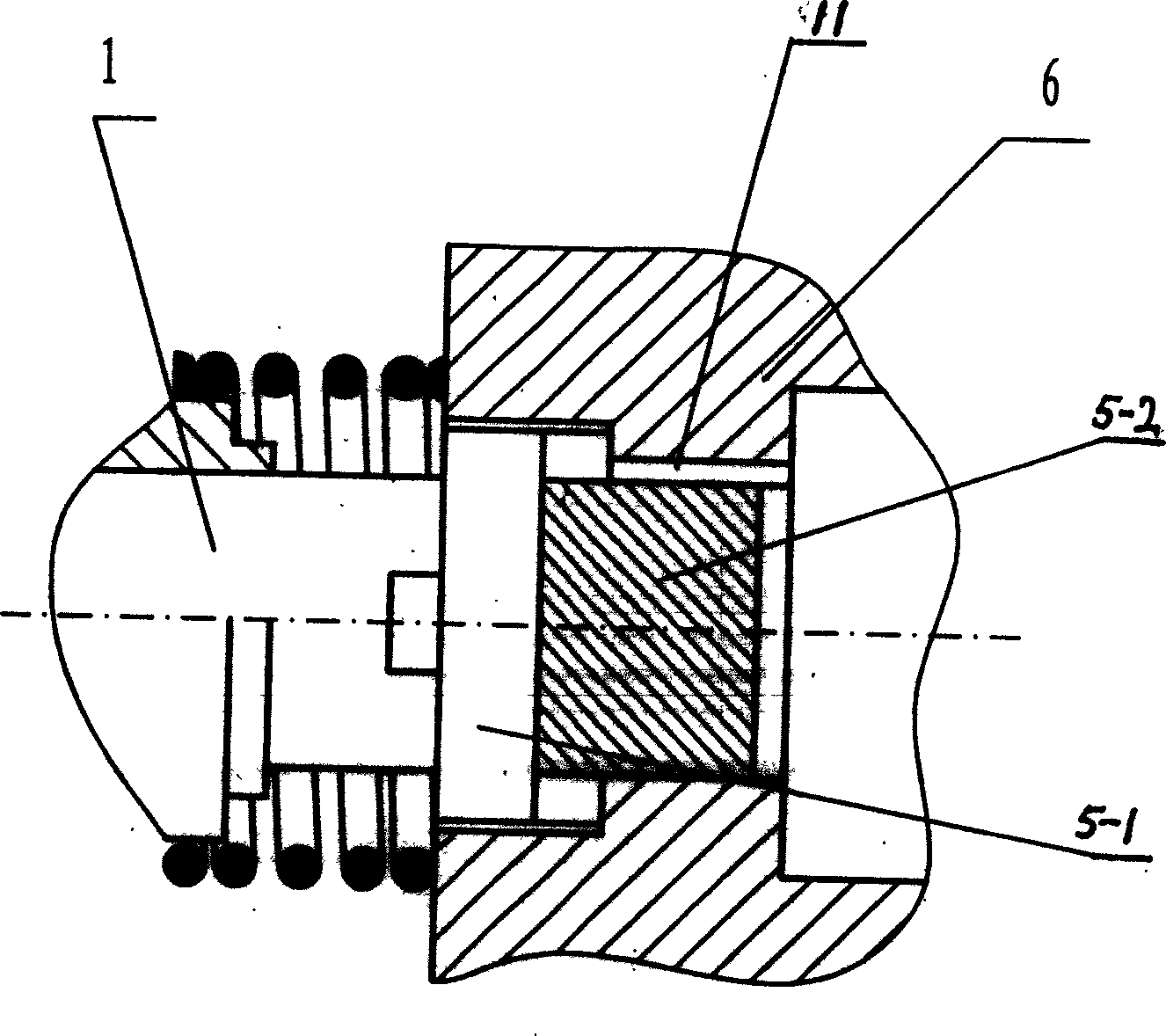

[0019] Such as figure 1 , image 3 As shown, the main slider (5-2) at the right end of the cross slider group (5) is connected with the cylinder body (6), the cylinder body (6) rotates and drives the sliding shoe plunger group (4) to rotate, and the sliding shoe column The plug group (4) is pressed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com