Electrical drive valve

An electric drive, stopper technology, applied in the direction of lift valve, valve device, engine components, etc., can solve the problems of wear of sliding parts, high touch energy, wear, etc., to improve durability and reliability, and improve wear resistance. damage, and the effect of preventing malfunction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Embodiments of the present invention will be described below with reference to the accompanying drawings.

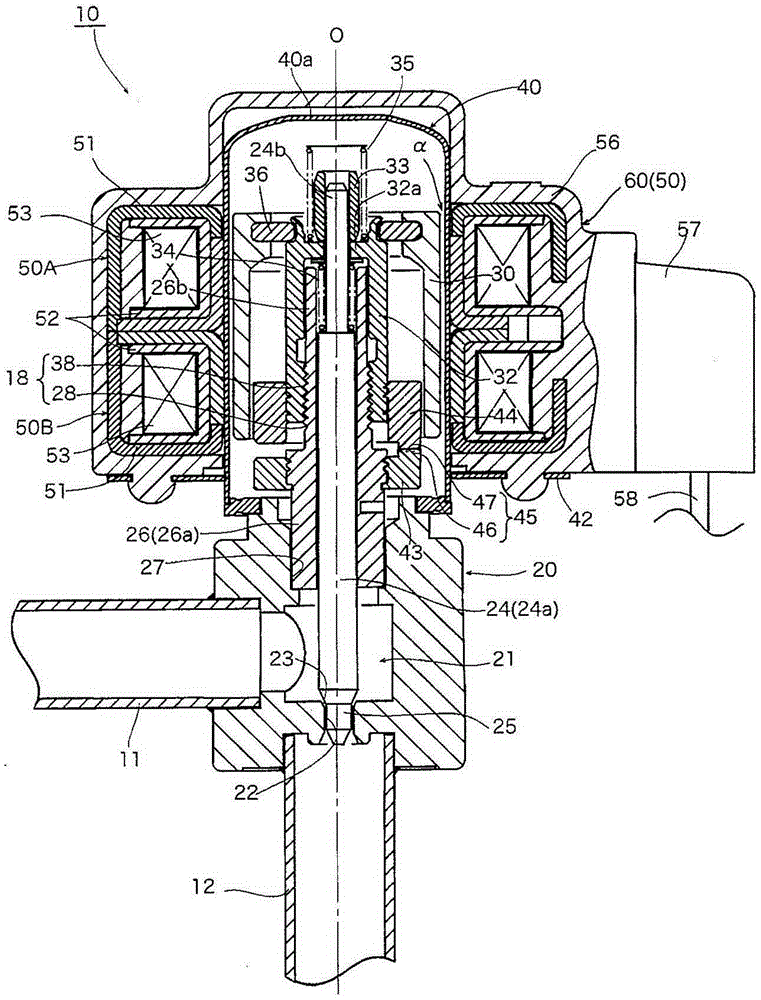

[0057] figure 1 An example of an electric valve as an electrically driven valve of the present invention is shown.

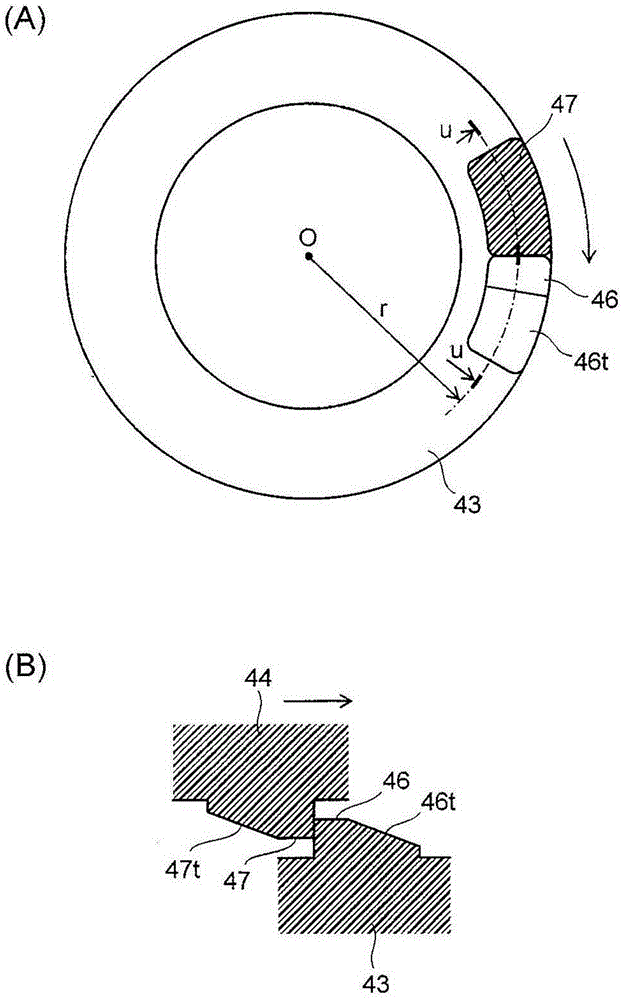

[0058] The electric valve 10 of the illustrated example has: a screw feed mechanism 18, which is used to utilize the rotation of the rotor 30 to make the valve core 25 contact and separate from the valve seat 23; The stopper 47 and the stopper mechanism 45 constituted by the fixed stopper 46 disposed on the valve seat 23 side (valve main body 20 side), before the valve core 25 is seated on the valve seat 23, the slightly opened micro-opening degree In the state, the movable stopper 47 is brought into contact with the fixed stopper 46 so as not to be in the closed state.

[0059] In detail, the electric valve 10 has: a valve shaft 24, the lower end of which is integrally provided with a valve core 25 having an inverted truncated cone; a valve main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com