Manufacturing method for door body used for refrigerator, door body used for refrigerator and refrigerator

A manufacturing method and door body technology, which is applied to household refrigeration devices, applications, household appliances, etc., can solve the problems of foaming material overflow, inability to effectively foam, and no thick refrigerator door body, etc., to achieve good sealing, The effect of reliable fixed connection relationship and stable overall frame structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

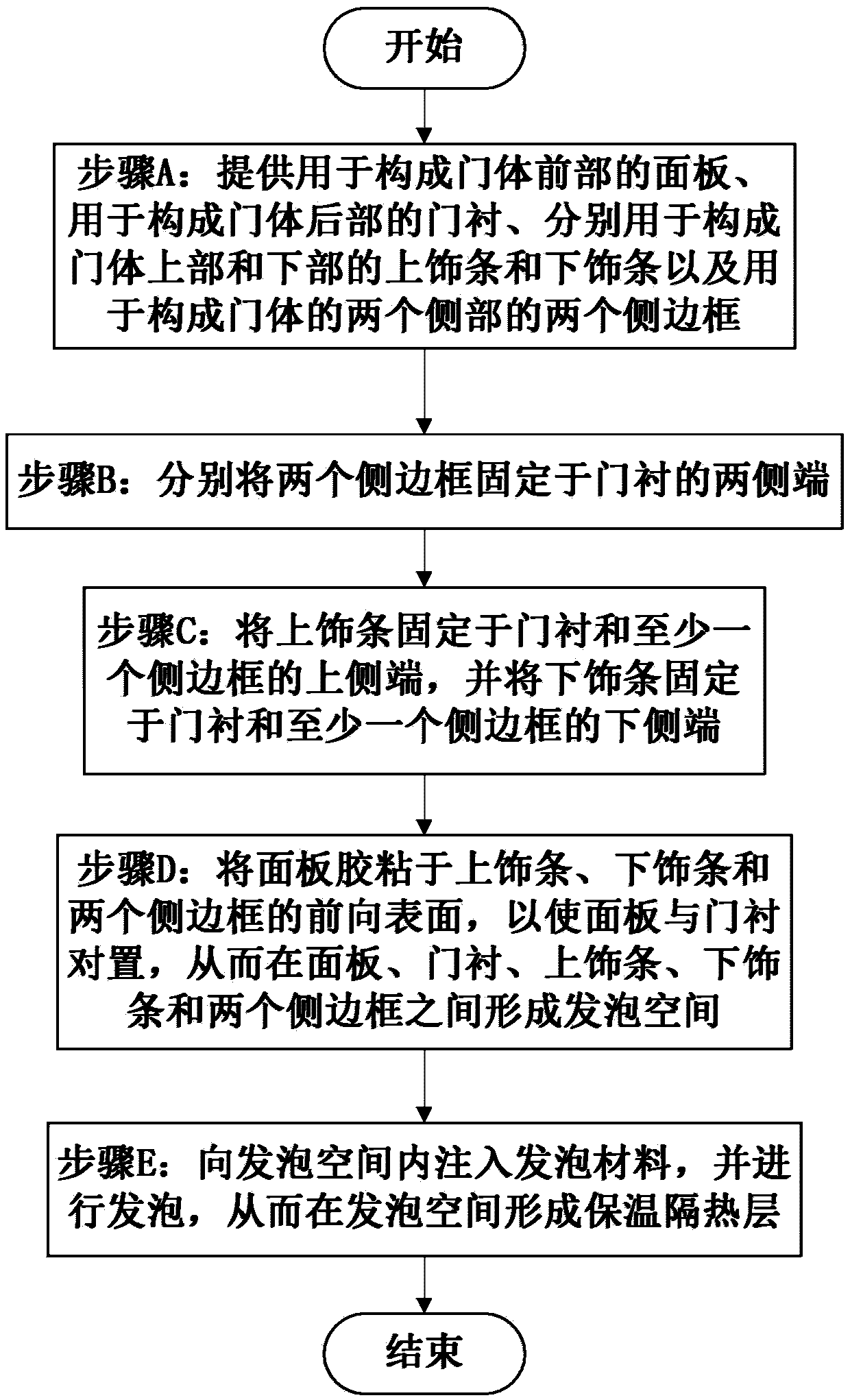

[0067] Embodiments of the present invention firstly provide a method for manufacturing a door body of a refrigerator. figure 1 It is a schematic flowchart of a method for manufacturing a refrigerator door body according to an embodiment of the present invention. see figure 1 , the manufacturing method of the embodiment of the present invention includes:

[0068] Step A: Provide a panel for constituting the front of the door body, a door liner for constituting the rear of the door body, upper and lower trim strips for constituting the upper and lower parts of the door body respectively, and two two side frames on one side;

[0069] Step B: Fix the two side frames to the two sides of the door liner respectively;

[0070] Step C: fixing the upper trim strip to the door liner and the upper end of at least one side frame, and fixing the lower trim strip to the door liner and the lower end of the at least one side frame;

[0071] Step D: Glue the panel to the front facing surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com