Rolling type coal sample drying device

A technology of drying device and coal sample, applied in drying, drying machine, drying gas arrangement and other directions, can solve the problems such as failure to effectively ensure the qualification of coal samples, no real-time and effective turning, uneven dehumidification, etc. The structure is simple, the interference of human factors is avoided, and the maintenance is convenient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

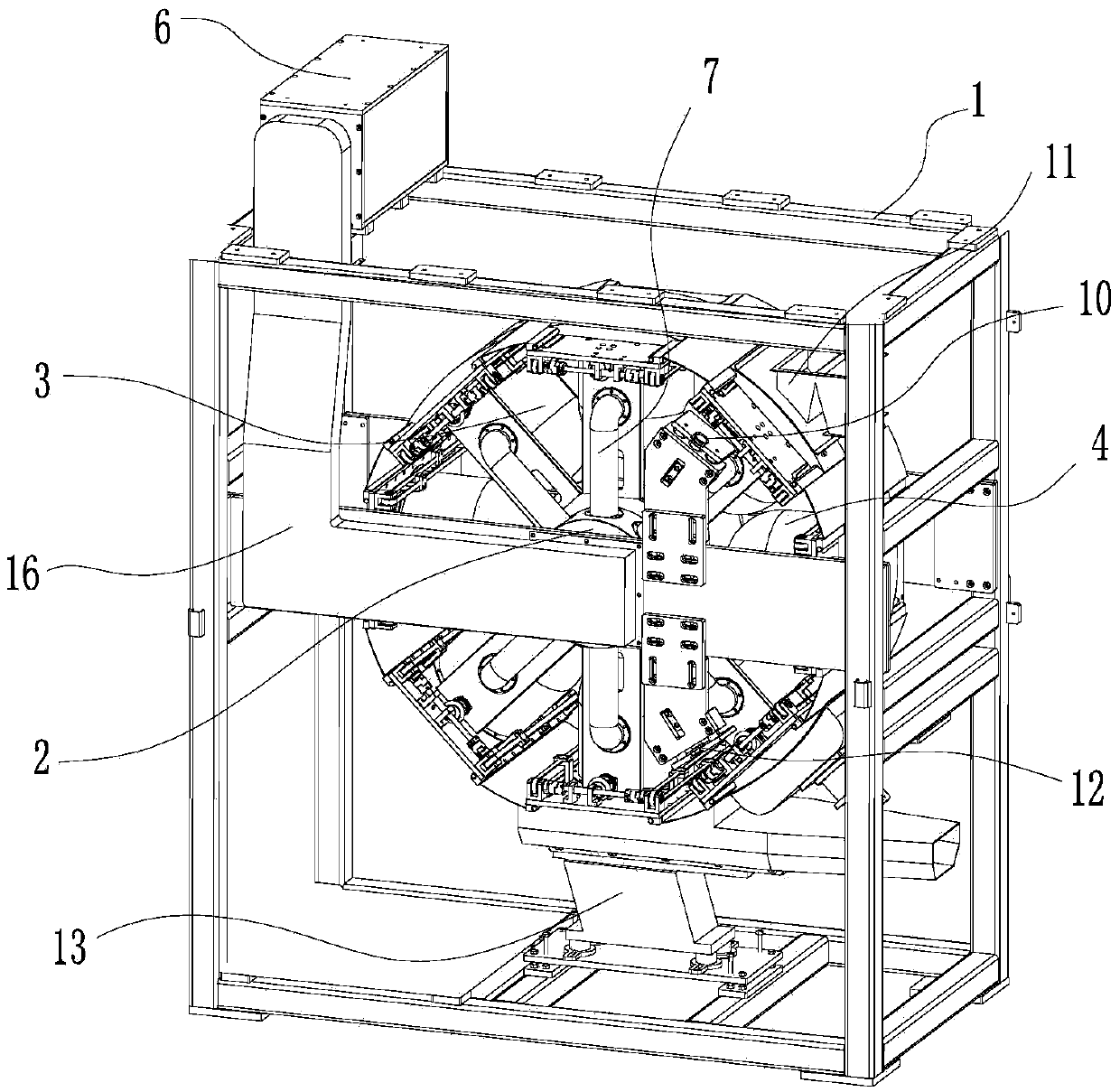

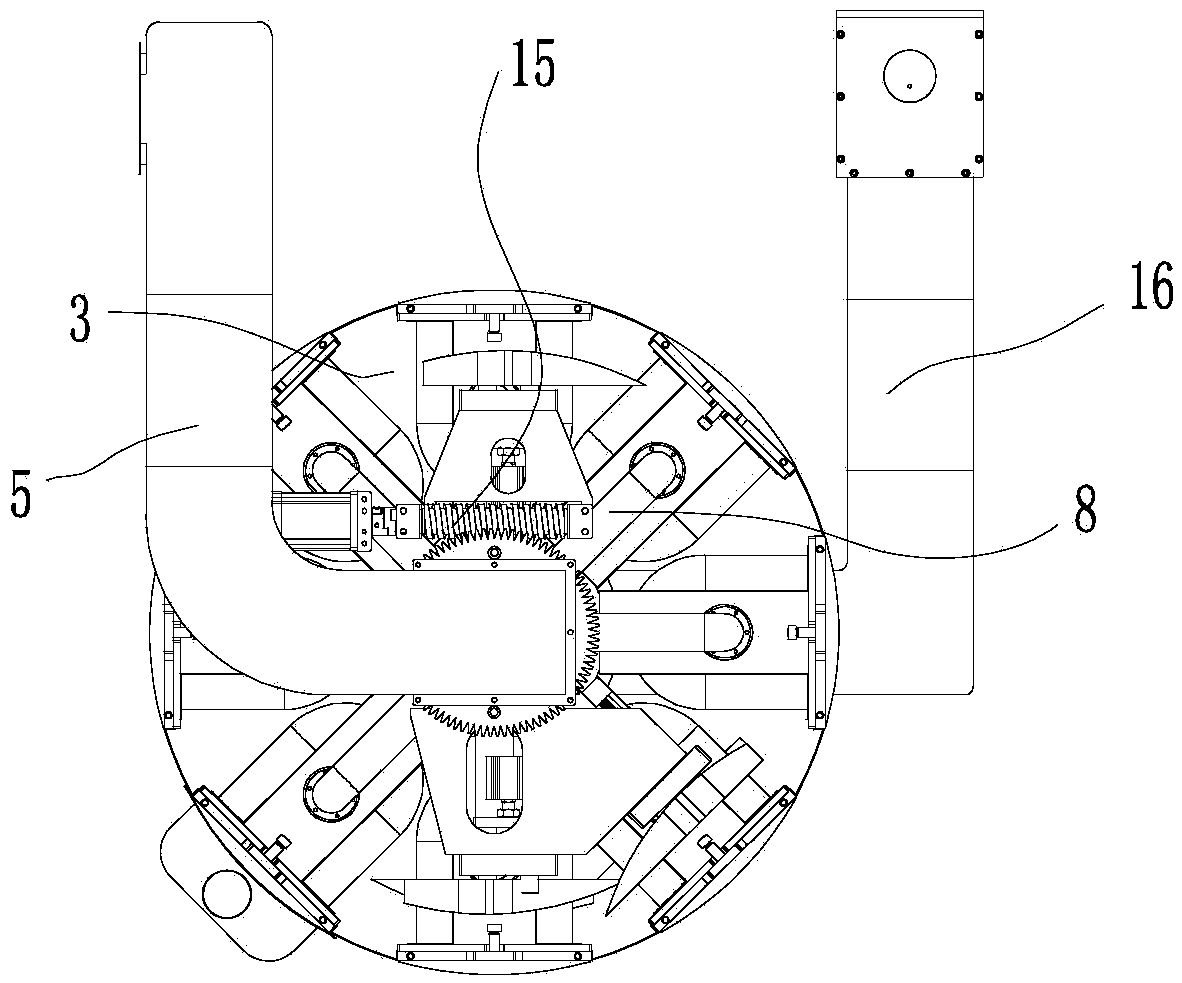

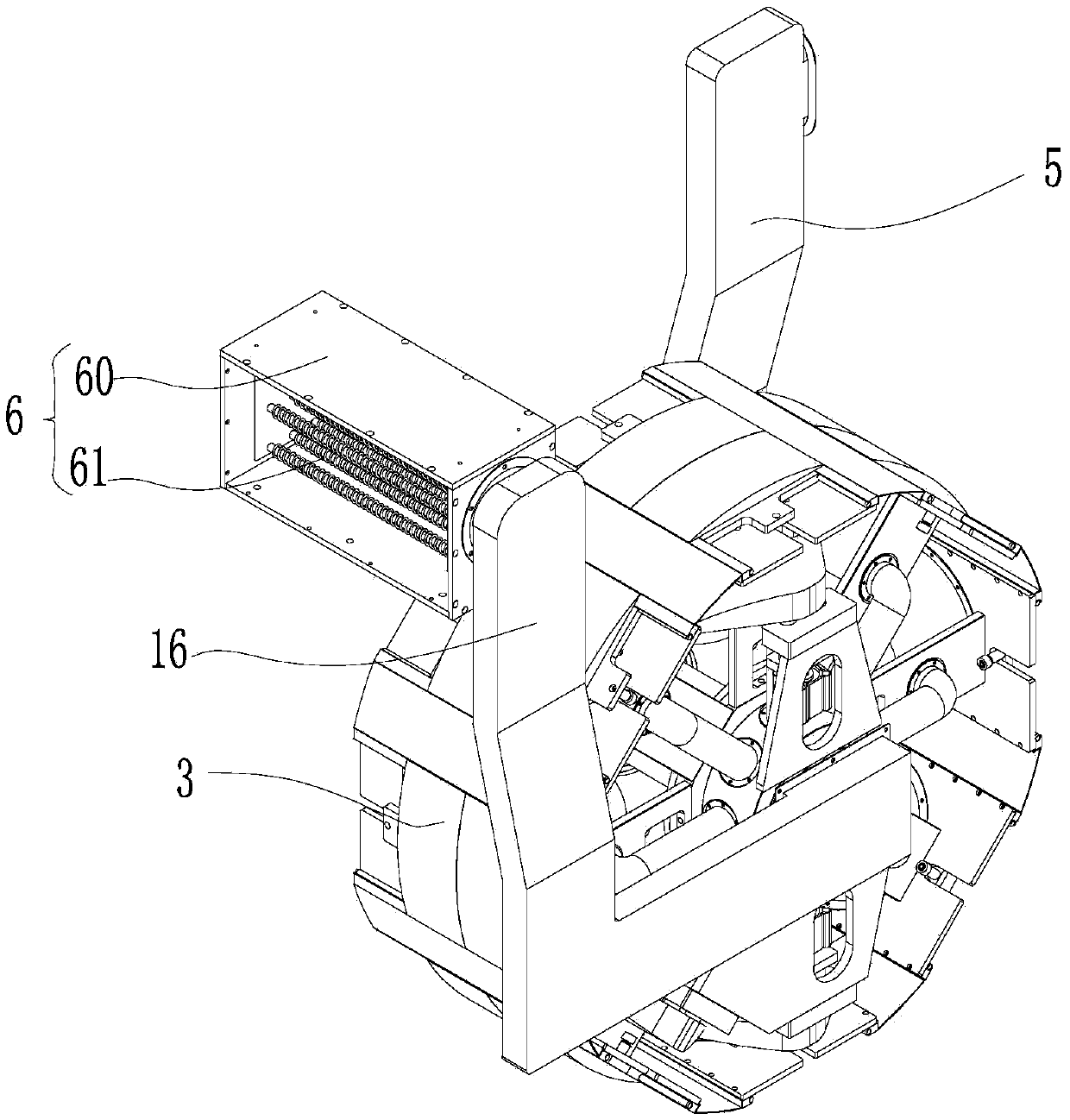

[0023] A tumbling type coal sample drying device, such as Figure 1 to Figure 5 As shown, it includes a frame 1, a hollow shaft 2 is installed in the center of the frame 1, and a rotating frame 3 that automatically rotates under power drive is installed on the hollow shaft 2, and 8 coal samples to be dried are installed on the rotating frame 3. the container 4; on the front side of the frame 1, an air inlet channel 16 communicating with the front end of the hollow shaft 2 and supplying air to each container 4 on the rotating frame 3 is installed; Connect and lead out the air outlet channel 5 of the dehumidified hot air in each container 4 on the rotating frame 3; a constant temperature device 6 for constant temperature heating of the blown air is also installed at the front end of the air inlet channel 16, and the constant temperature device 6 includes a drying box 60 and an electric heater 61 arranged in the drying oven 60.

[0024] continue as Figure 1 to Figure 5 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com