A partitioned mems fuze

A partition type fuze technology, applied in the direction of fuzes, weapon accessories, offensive equipment, etc., can solve problems such as breakthroughs and constraints on technological development, and achieve the effects of increasing yield, high degree of intelligence, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

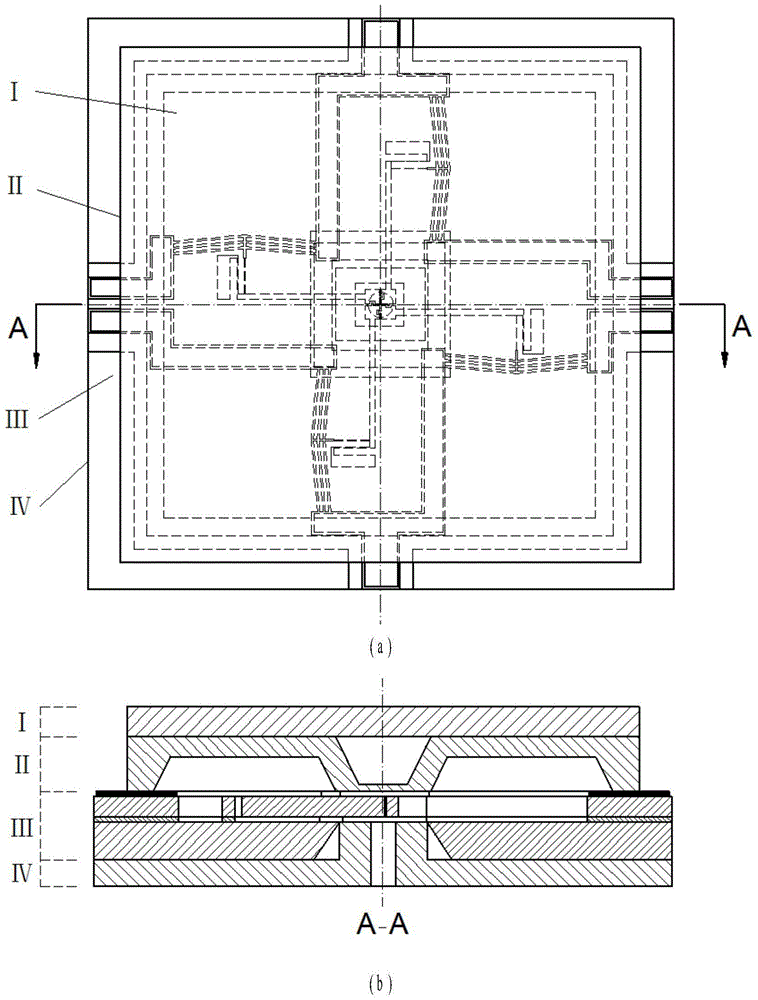

[0022] refer to figure 1 , a partition type MEMS fuze, including agent cover layer I, agent layer II, security device layer III and acceleration chamber layer IV, the upper part of agent layer II and agent cover layer I are connected by bonding, and the lower part of agent layer II It is connected with the upper part of the security device layer III by bonding, and the lower part of the security device layer III is pasted with the acceleration chamber layer IV.

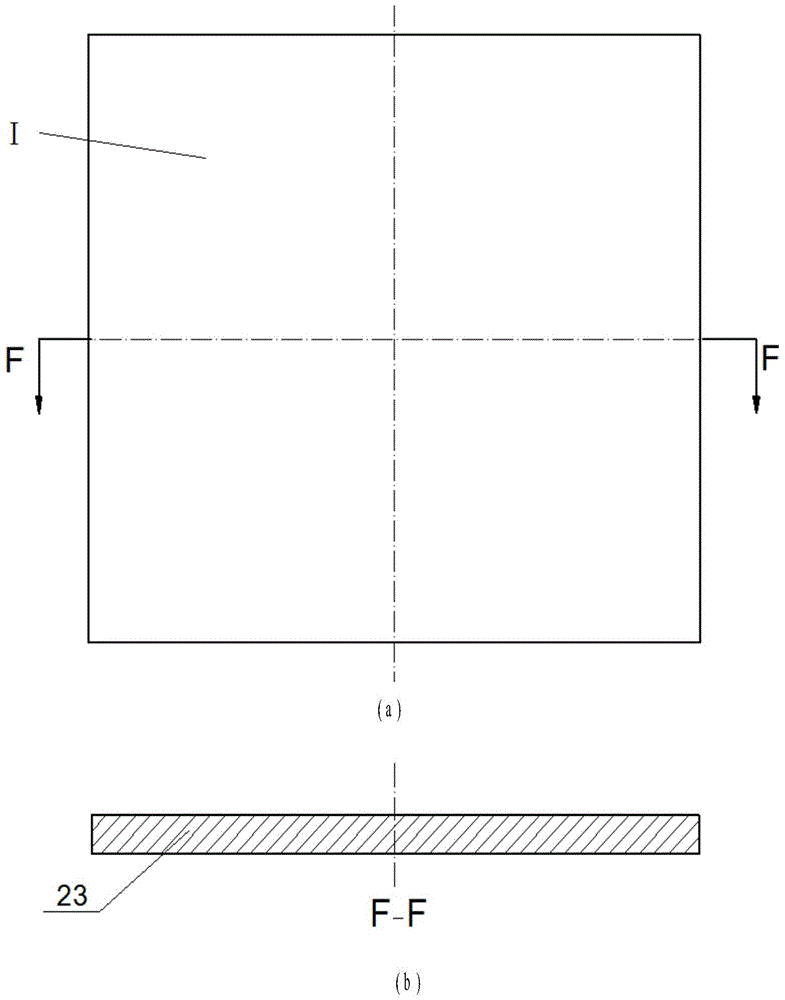

[0023] refer to figure 2 , the drug cover layer I includes a drug cover 23, the drug cover 23 is a square sheet of single crystal silicon material with a side length of 7.5mm-8mm and a thickness of 0.2mm-0.3mm.

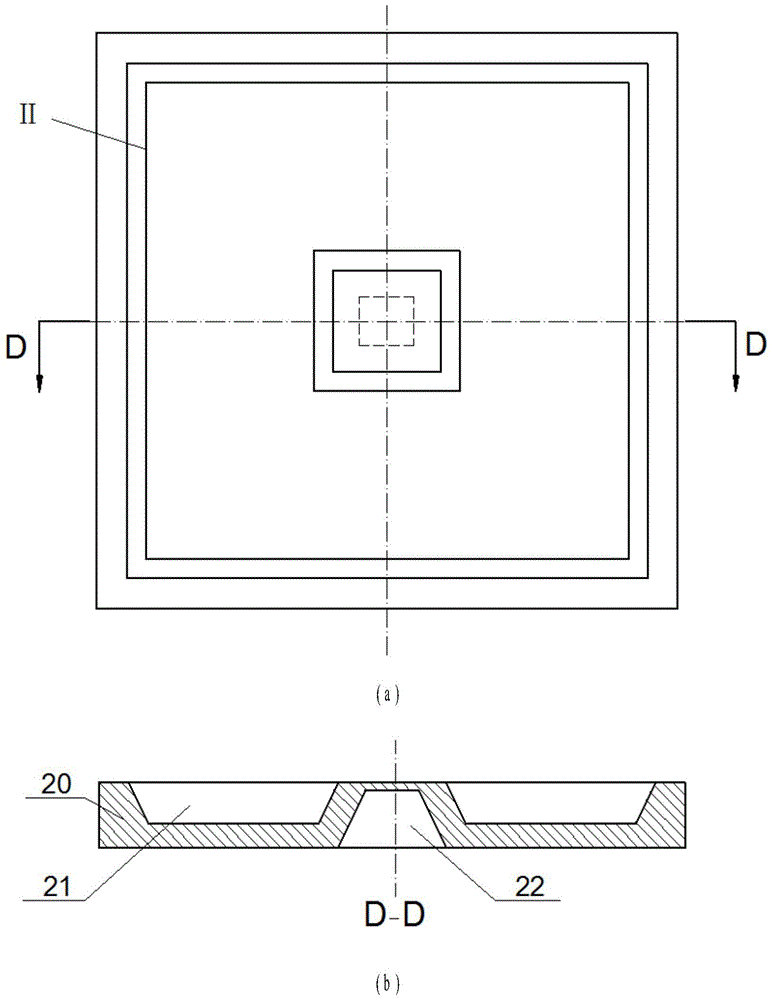

[0024] refer to image 3 , the drug layer II includes a drug layer wall 20, the drug chamber 22 is located below the center of the drug layer wall 20, and is used to fill the priming agent, the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com