Orthogonal self-calibration branch double-ball decoupling six-dimensional force measuring platform

A self-calibration and branching technology, applied in the field of sensors, can solve the problems of small friction coupling, multi-dimensional force sensor coupling and complex decoupling technology, etc., and achieve the effect of simple calibration, convenient installation and debugging, and clear input-output relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

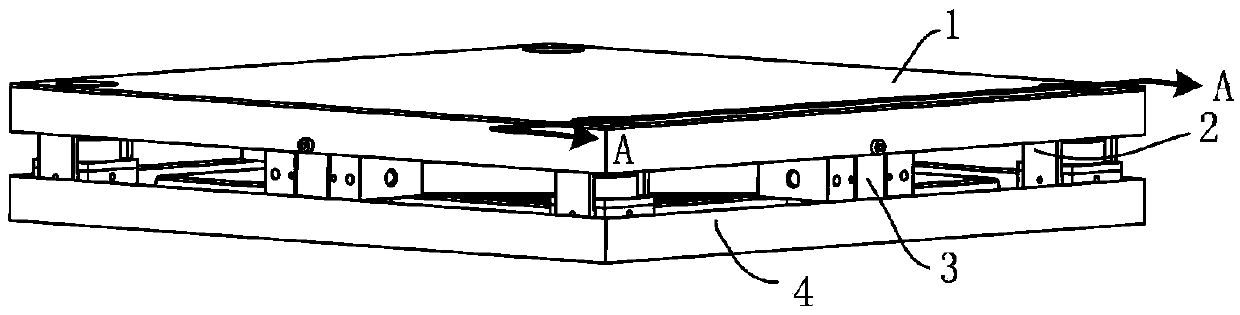

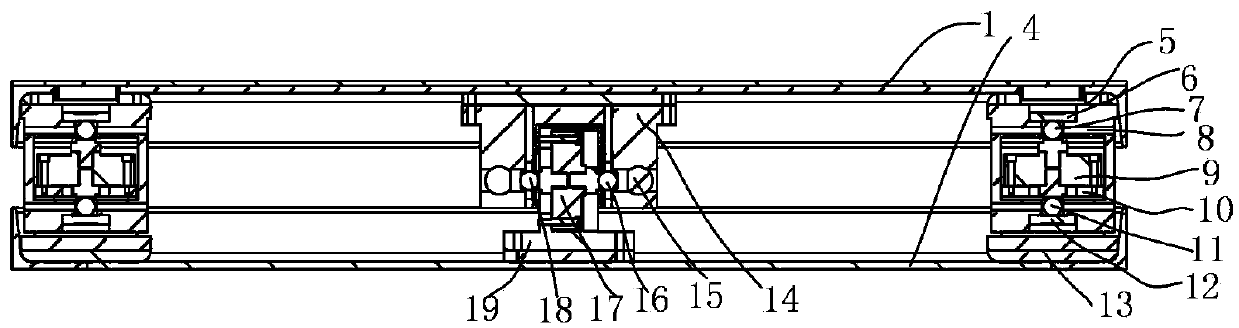

[0022] exist figure 1 , figure 2 In the schematic diagram of the orthogonal self-calibration weakly coupled heavy-duty parallel six-dimensional force measuring platform shown, the vertical force measuring branch 2 of the upper platform 1 and the lower platform 4 is decoupled by four double balls and the four double balls are decoupled horizontally. The force measuring branches are connected by 3, and the two branches are equal in number, and are evenly distributed between the upper platform and the lower platform;

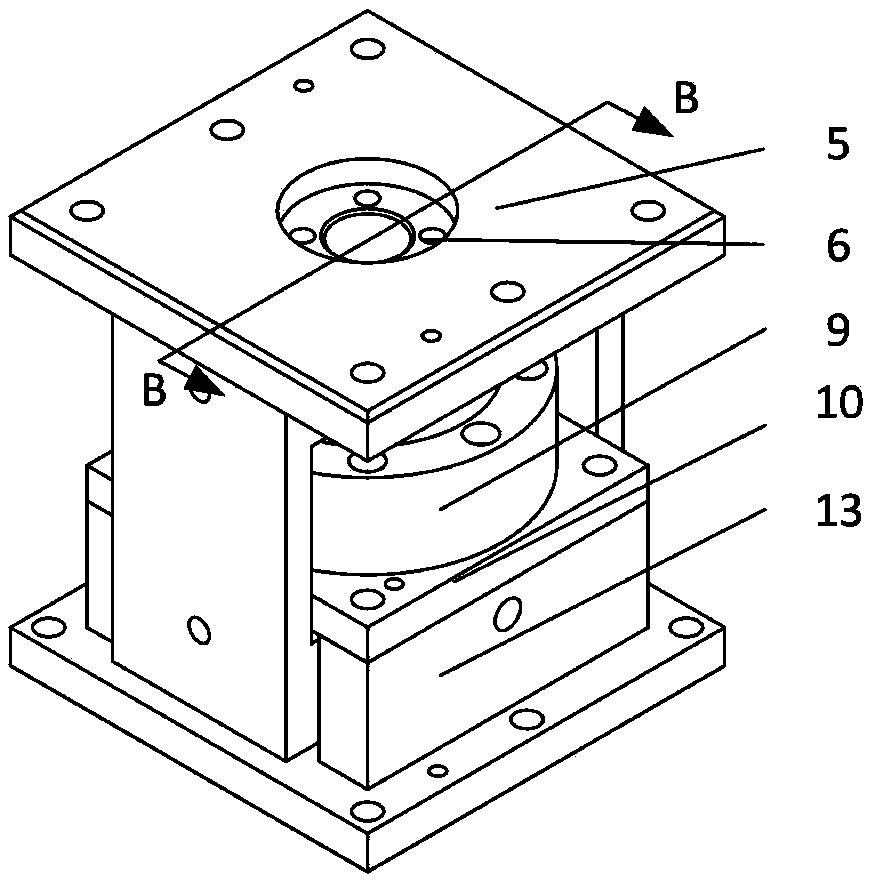

[0023] Double ball decoupling vertical force measurement branch such as image 3 and Figure 4 As shown, the upper support 5 of the vertical branch in the vertical force measuring branch of the double-ball decoupling is a square frame structure with a top cover, and a through hole is provided in the middle of the upper support of the vertical branch. There is an upper compression end cover 6, and an upper decoupling steel ball 7 is provided between the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com