Bright spot inspection device for lithium battery diaphragm

A technology of lithium battery separator and inspection device, which is applied to measurement devices, material analysis by optical means, instruments, etc., can solve the problems of low inspection efficiency, unevenness and jitter, and excessive operation factors, and achieves the improvement of inspection efficiency, Guaranteed inspection accuracy and high inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

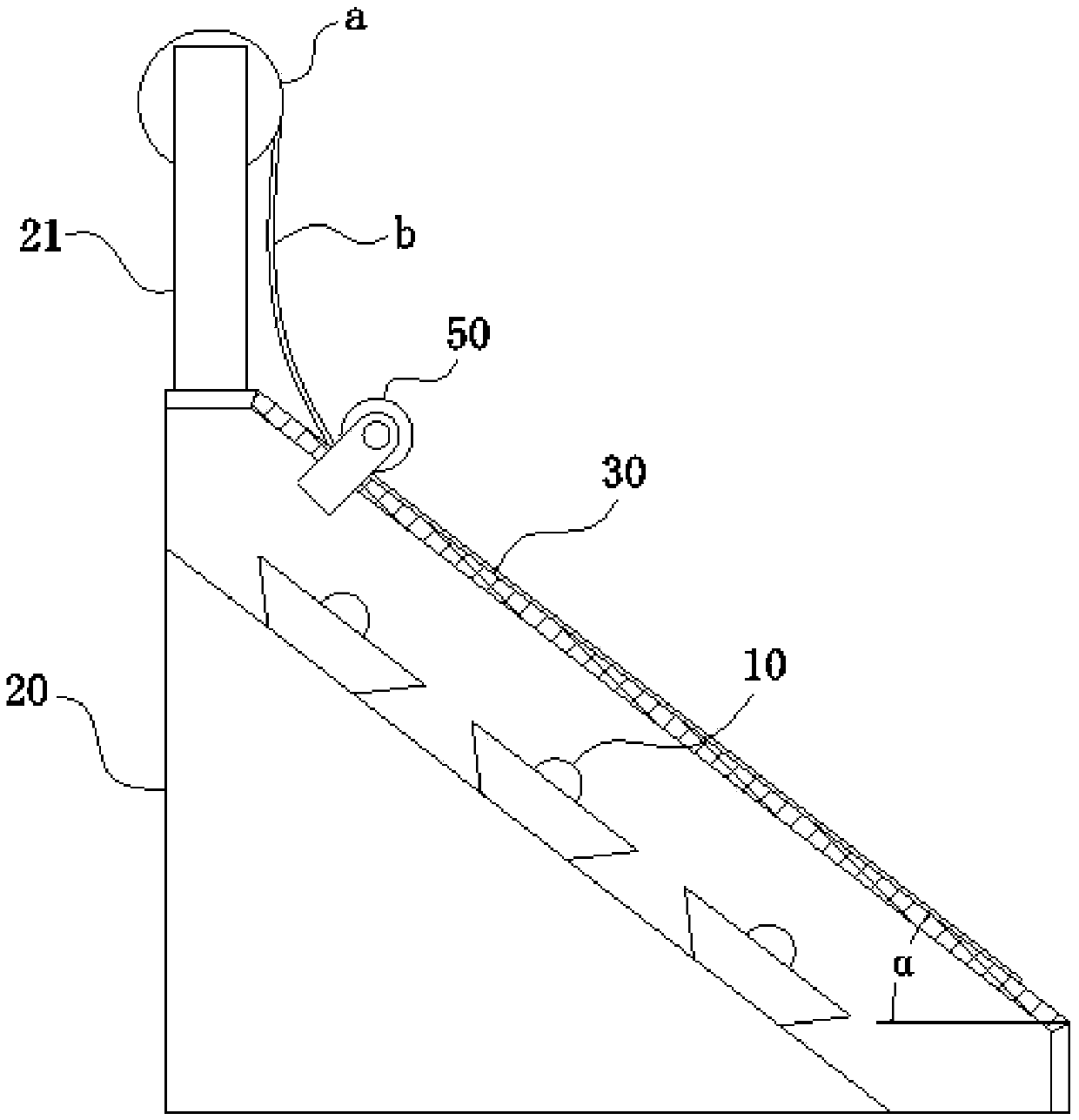

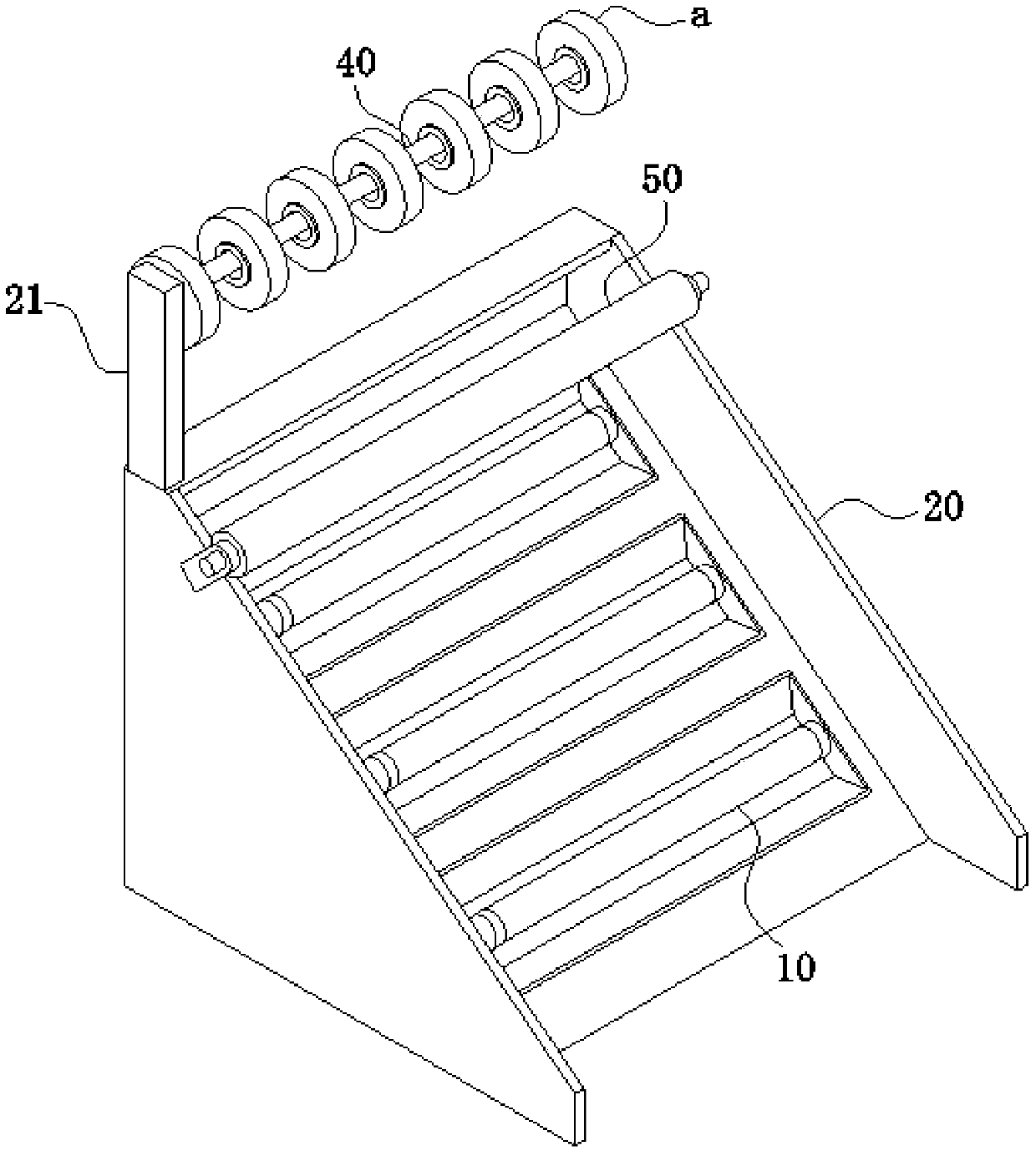

[0024] For ease of understanding, combined here Figure 1-3 The specific implementation structure and work flow of the present invention are described as follows:

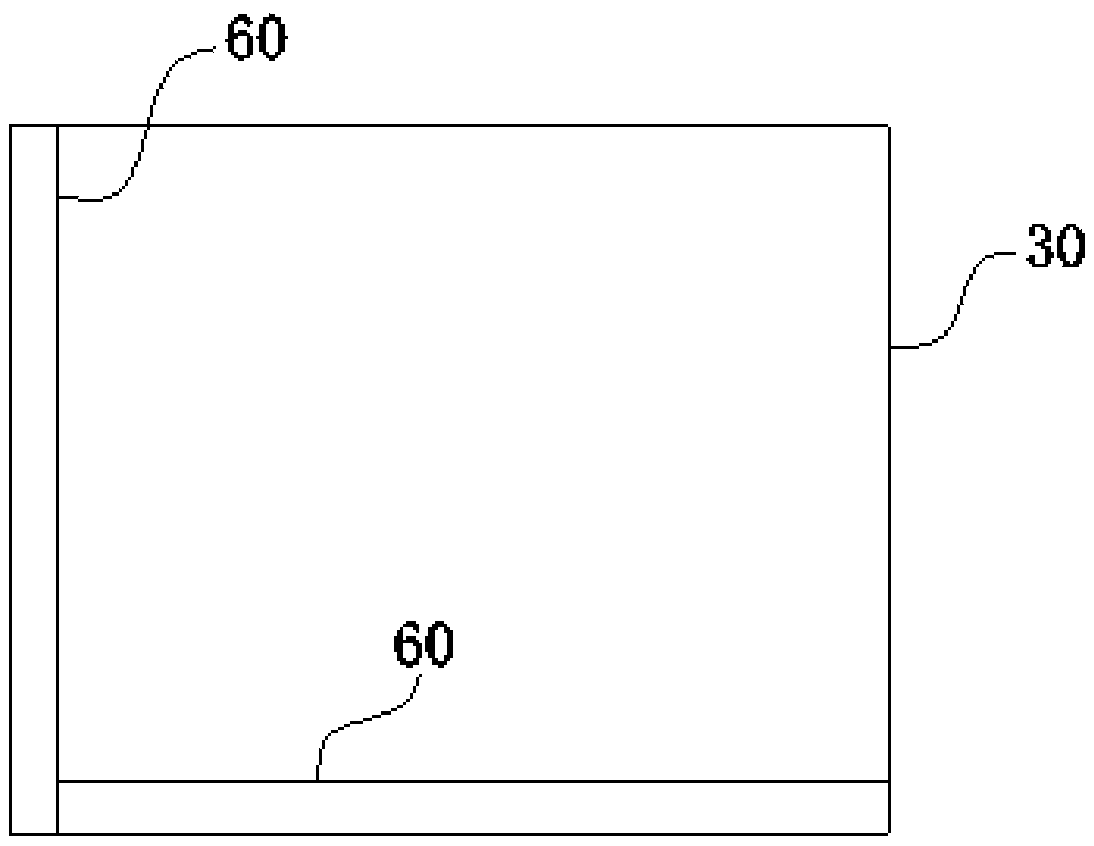

[0025] The concrete implementation structure of the present invention, as Figure 1-3 As shown, it includes: light box 20, fluorescent lamp (ie light source 10), unwinding reel 40, scaled acrylic plate (ie transparent plate 30), guide roller 50, scale 60, switch. Wherein, the shape of the light box 20 is a triangular box with right-angled sides, and its inner cavity forms a fixed cavity for installing and fixing the fluorescent lamp. The entire slope of the light box 20 is arranged at 30-45°, and the entire slope is formed by laying an acrylic plate with a scale 60 . At the top of the acrylic plate, such as figure 1 The guide roller 50 whose axis is parallel to its plate surface is set as shown; above the top of the acrylic plate, an unwinding shaft 40 whose axis is parallel to its plate surface is arranged, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com