Detection method of transition degree of oil-based drilling fluid

A technology of oil-based drilling fluid and detection method, which is applied in the direction of measuring device, material analysis through electromagnetic means, instruments, etc., can solve the problem that it is difficult to accurately judge the complete conversion of oil-based drilling fluid, the interruption of the conversion construction process, and the deviation of displacement measurement and other issues, to achieve good reliability and practicability, and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

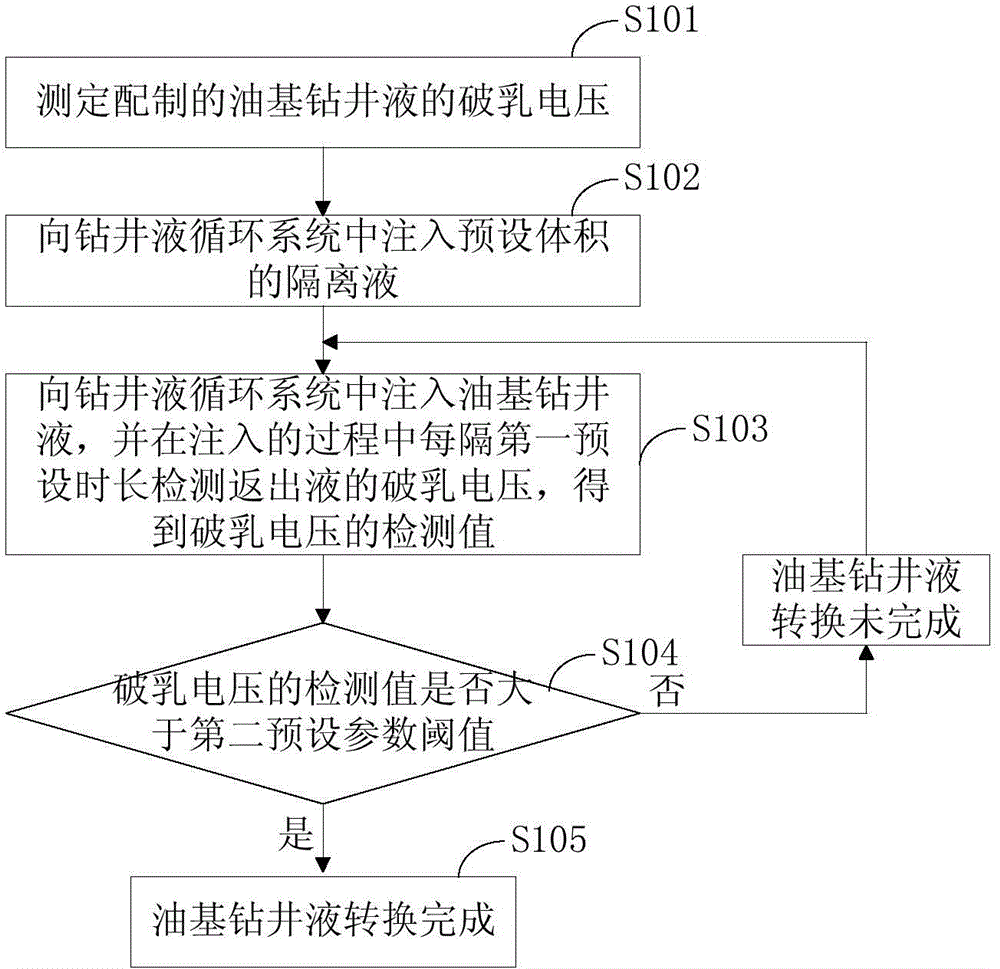

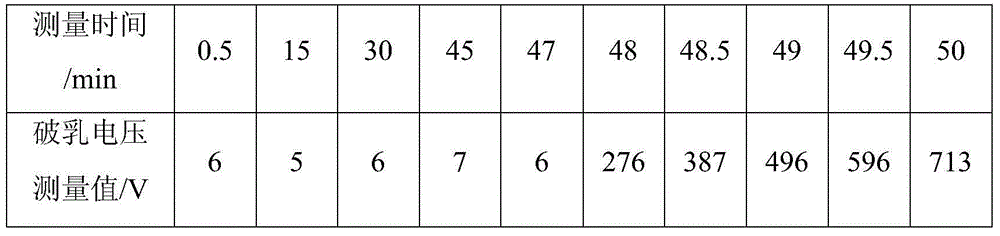

[0031] In view of the defect that the observation method or the displacement calculation method cannot accurately judge whether the conversion of the oil-based drilling fluid is completed, this embodiment provides a method for detecting the conversion degree of the oil-based drilling fluid based on the demulsification voltage of the oil-based drilling fluid , figure 1 A flowchart of the method is shown.

[0032] In this example, the water-based drilling fluid of Well X1 in the Sichuan Basin is converted into diesel-based drilling fluid, where the wellbore volume of Well X1 is 140m 3 , the total capacity of the surface circulation system is 320m 3 .

[0033] like figure 1 As shown, in this embodiment, firstly, in step S101 of determining the parameter configuration value, the preset parameters of the prepared oil-based drilling fluid are measured to obtain the preset parameters of the oil-based drilling fluid.

[0034] In this embodiment, the volume of the prepared oil-base...

Embodiment 2

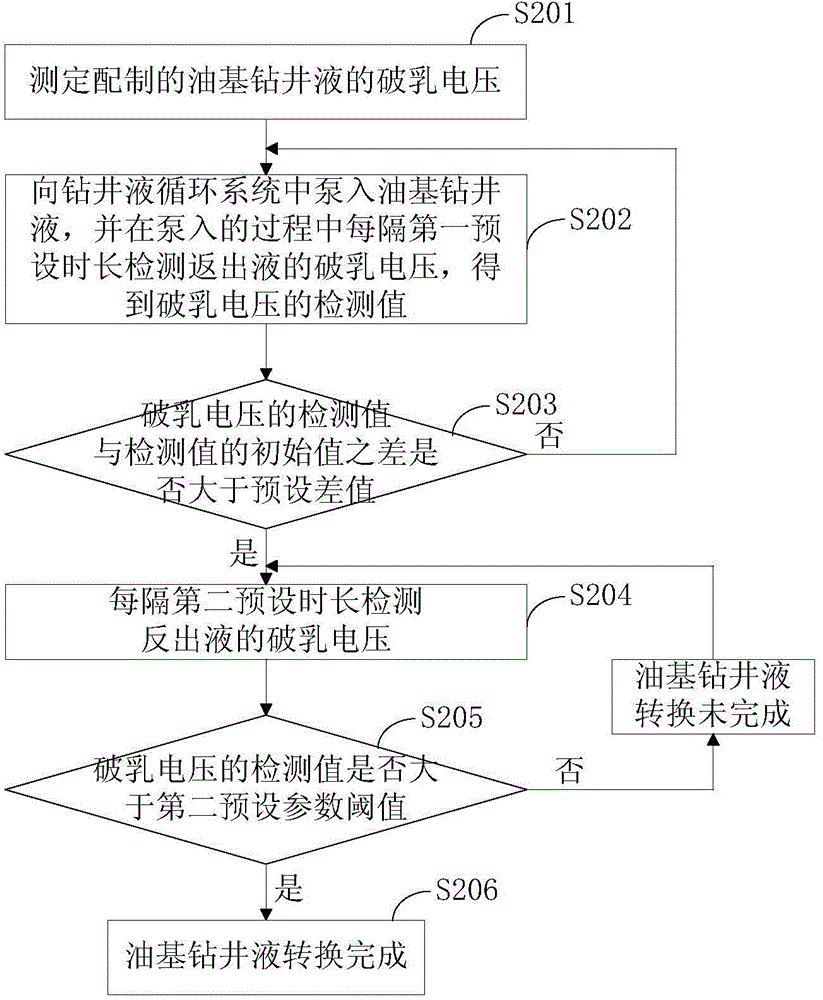

[0048] In this example, the method provided by the present invention is used to convert the water-based drilling fluid of Well X2 in the Tarim Basin into a mineral oil-based drilling fluid, so as to further illustrate the purpose, principle and advantages of the present invention.

[0049] Well X2 in the Tarim Basin has a shaft capacity of 220m 3 , the total capacity of the surface circulation system is 200m 3 . Since the total capacity of the surface circulation system is smaller than the wellbore capacity of Well X2, the oil-based drilling fluid cannot be pumped in one time, but needs to be pumped into the drilling fluid circulation system twice, so that the conversion can be completed .

[0050] figure 2 A flow chart of the method for detecting the conversion degree of oil-based drilling fluid provided in this embodiment is shown.

[0051] like figure 2 As shown, the present embodiment first prepares 160m in the on-site ground circulation system in step S201 3 After...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com