Method of restraining notch appearing at bottom of hole during etching process, and hole forming method

A technology for etching holes and gaps, which is used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., and can solve problems such as deterioration of device performance, damage to shape, and processing process problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

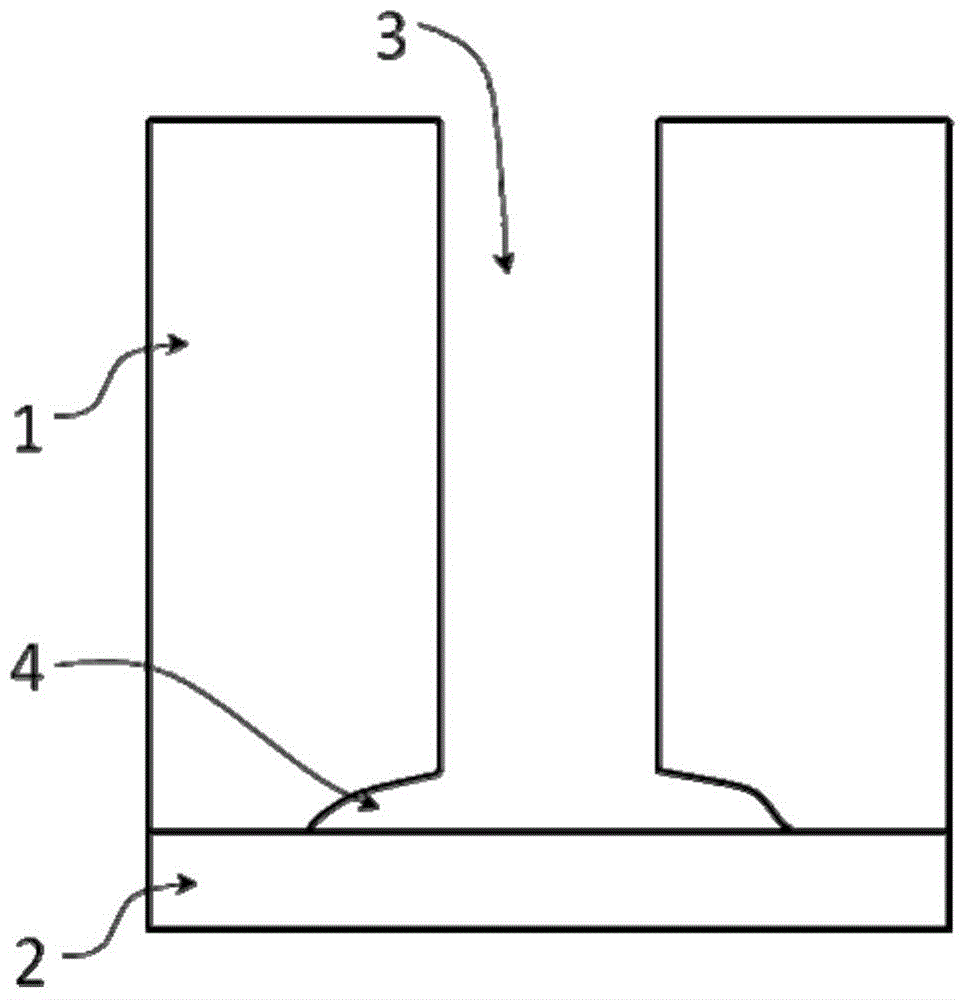

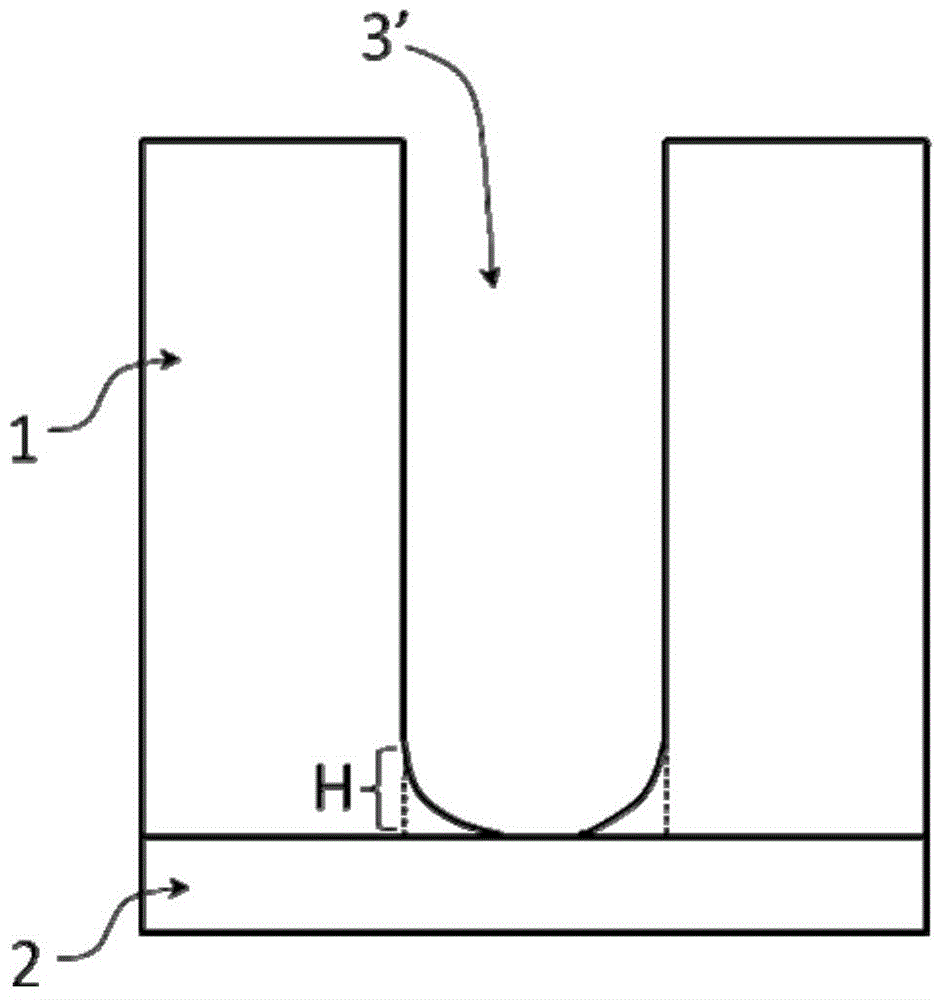

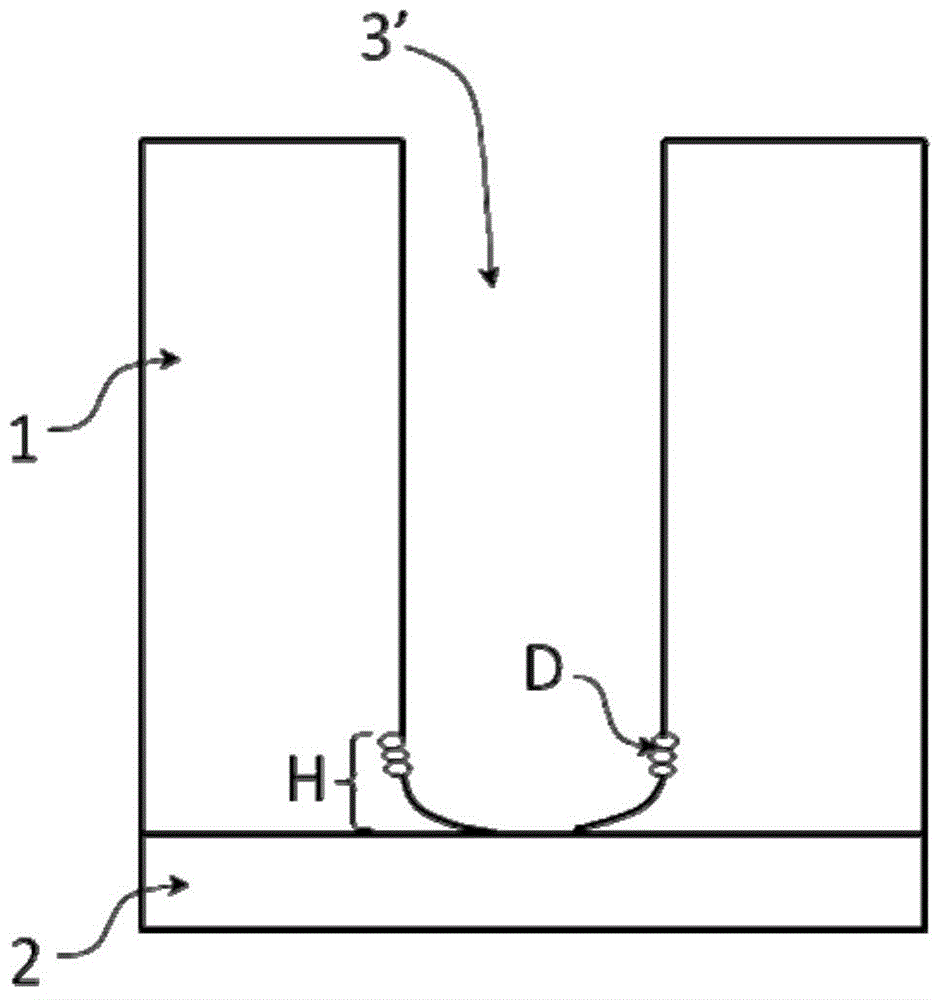

[0024] The current research theory generally believes that in plasma etching, the generation of notching at the bottom of the hole is directly related to the accumulation of charges on silicon (or other materials). Therefore, the idea of suppressing the notch phenomenon is usually to neutralize the accumulated charges on the silicon surface. , or directly reduce the amount of charge that ions transfer to silicon. Specific measures include reducing the frequency of the radio frequency (lower frequency), applying pulsed generators to the radio frequency power supply, and reducing the duty cycle (duty cycle, also known as the duty cycle) and so on.

[0025] While studying the subject of notch elimination, the inventors discovered a new factor that can affect the notch: the gas pressure of plasma etching. When other parameters remain unchanged, the lower the working air pressure, the more obvious the improvement of the notch phenomenon.

[0026] In plasma etching, the surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com