Dry etching preparation method of T-shaped hole of integrated circuit

A technology of dry etching and integrated circuits, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., and can solve problems such as expensive, increased company costs, and inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Aiming at the above-mentioned technical solution, a preferred embodiment is given and described in detail with reference to the drawings.

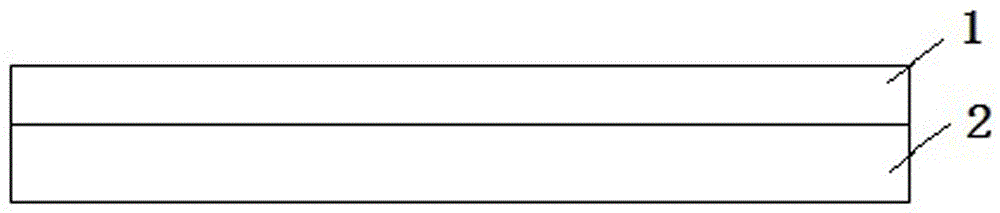

[0020] First, see figure 1 , Deposit isolation dielectric 2 for metal interconnection on doped silicon substrate or isolation dielectric 1 formed by atmospheric pressure CVD deposition, isolation dielectric 2 is deposited by plasma deposition (PECVD), and control isolation dielectric 2 The thickness is 2.3 microns, which is used as a semiconductor substrate for making T-shaped holes.

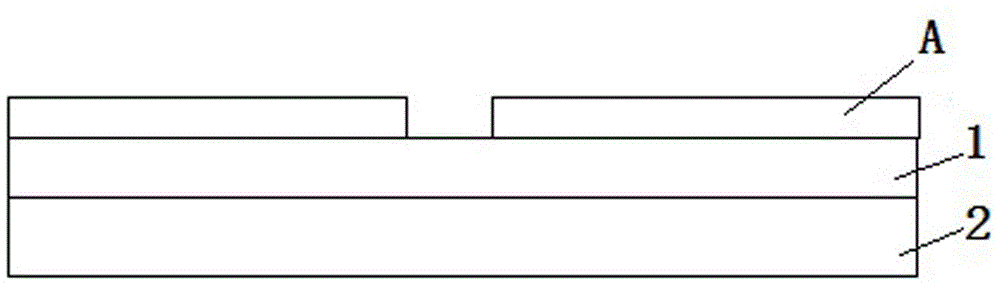

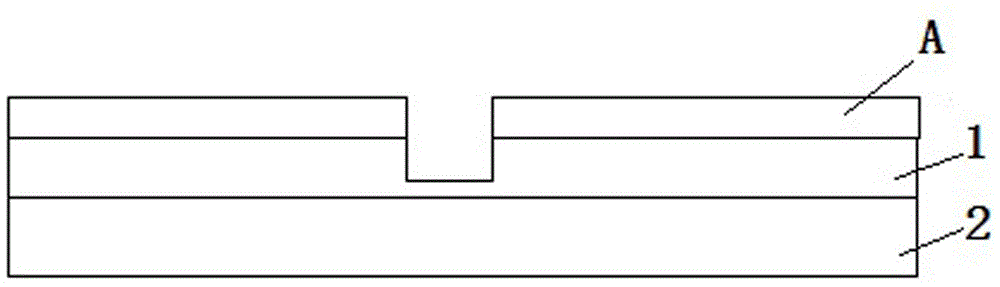

[0021] Step 1), one photolithography, to make fine hole etching window, see figure 2 , a photolithography is performed on the isolation dielectric layer for metal interconnection to make a fine hole etching window. The specific steps are:

[0022] Uniform glue, uniform glue adopts 5370 photoresist provided by Kehua photoresist factory to carry out glue uniformity, and the thickness of photoresist A is controlled at 2.8 microns.

[0023] Exposure,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com