Pressure induced gas generator system for electrolysis

A gas generator and main body technology, applied in electrical control, electrolysis components, electrolysis process, etc., can solve problems such as expensive and redesigned exhaust systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

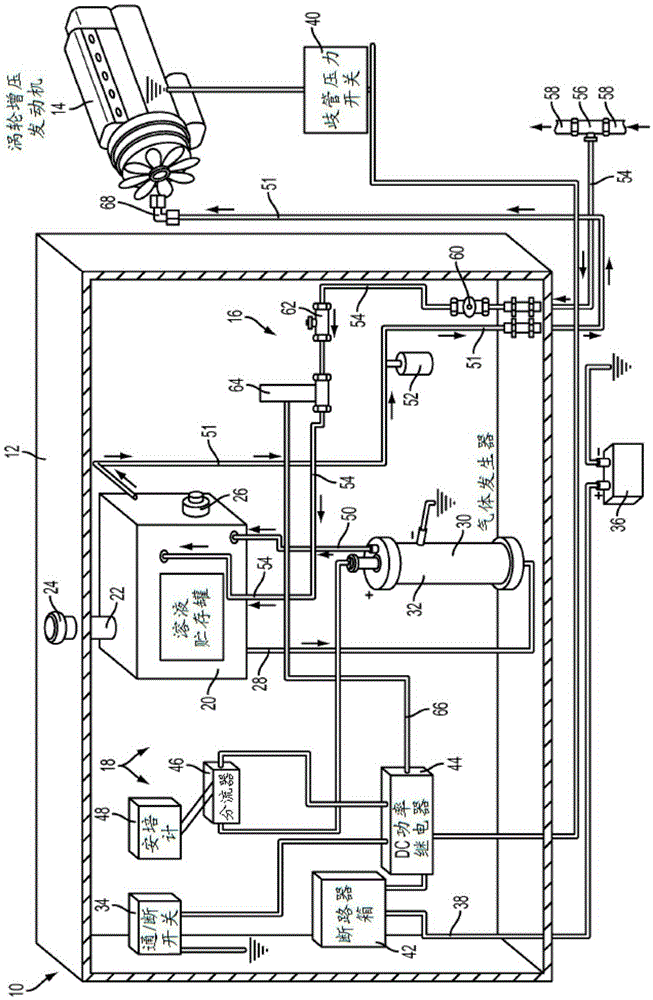

[0024] figure 1 is a schematic illustration of a pressurized electrolysis system according to embodiments discussed herein. The pressurized electrolysis system is generally identified by reference numeral 10 . Pressurized electrolysis system 10 is mountable in system housing 12 and is adapted to introduce a pressurized gas mixture to an engine. exist figure 1 In, by way of example and not limitation, a pressurized electrolysis system 10 is shown introducing a pressurized gas mixture into the intake manifold of a turbocharged diesel engine 14 . The pressurized electrolysis system 10 according to the present disclosure may also be used with other types of engines, such as gasoline engines, diesel engines, natural gas piston driven engines, turbine driven petroleum engines, natural gas combustion engines, or jet engines. Pressurized electrolysis system 10 may include air pressure system 16 and gas generator system 18 .

[0025] The gas generator system 18 includes a solution ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap