Spray nozzle for electrostatic spraying of a coating product and facility for spraying a coating product including such a spray nozzle

An electrostatic spraying and product technology, applied in the direction of electrostatic spraying device, spraying device, spraying device, etc., to achieve the effect of easy operation, improved safety, and improved resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

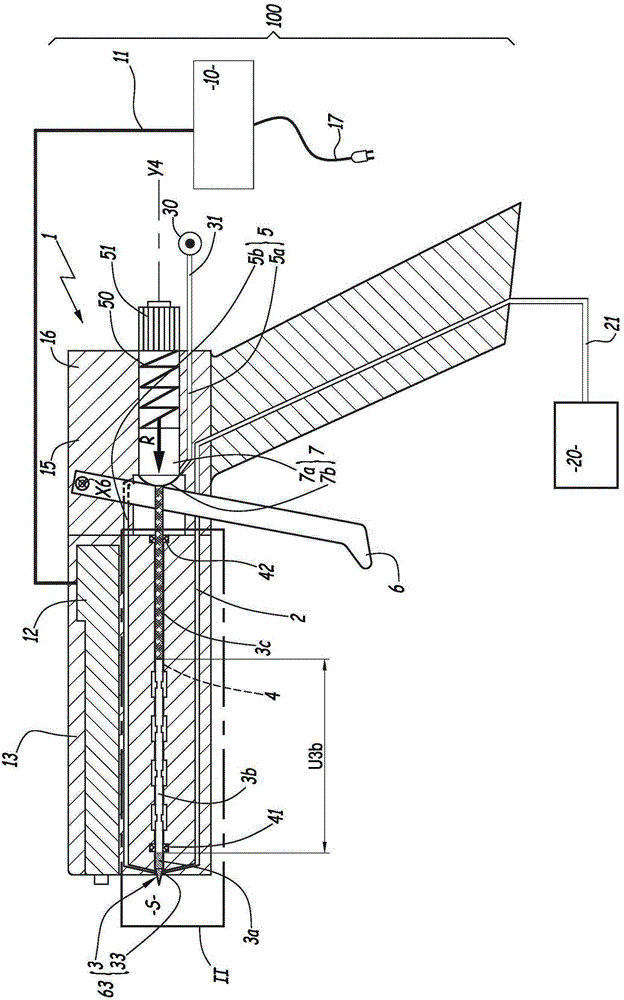

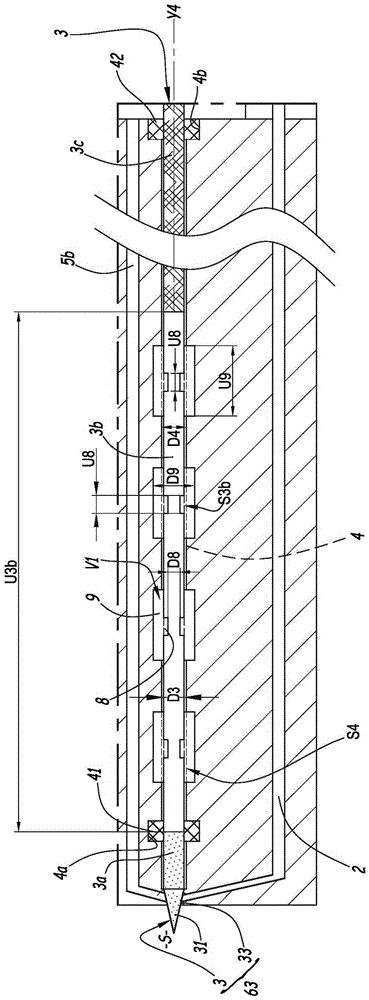

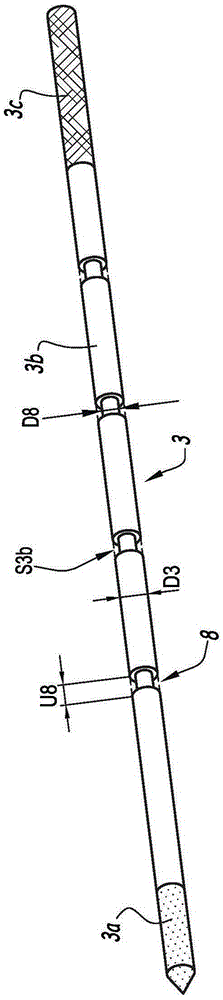

[0028] figure 1 The apparatus 100 shown in FIG. 2 enables electrostatic painting of objects (not shown). The apparatus 100 comprises a spray gun 1 for electrostatic spraying of a paint product, the spray gun 1 being supplied with paint product from a paint product reservoir 20 via a hose 21 .

[0029] The spray gun 1 is also connected to a source of charge air 30 by a hose 31 . Air from the source 30 is used to spray the paint product by driving it from the spray gun 1 towards the object to be painted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com