Drum-type washing machine

A drum-type washing machine and drum technology, which is applied to other washing machines, washing machines with containers, control devices of washing machines, etc., can solve the problems of unbalanced ball balancer, abnormal vibration, large drum vibration amplitude, etc., so as to suppress imbalance and reduce unbalanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

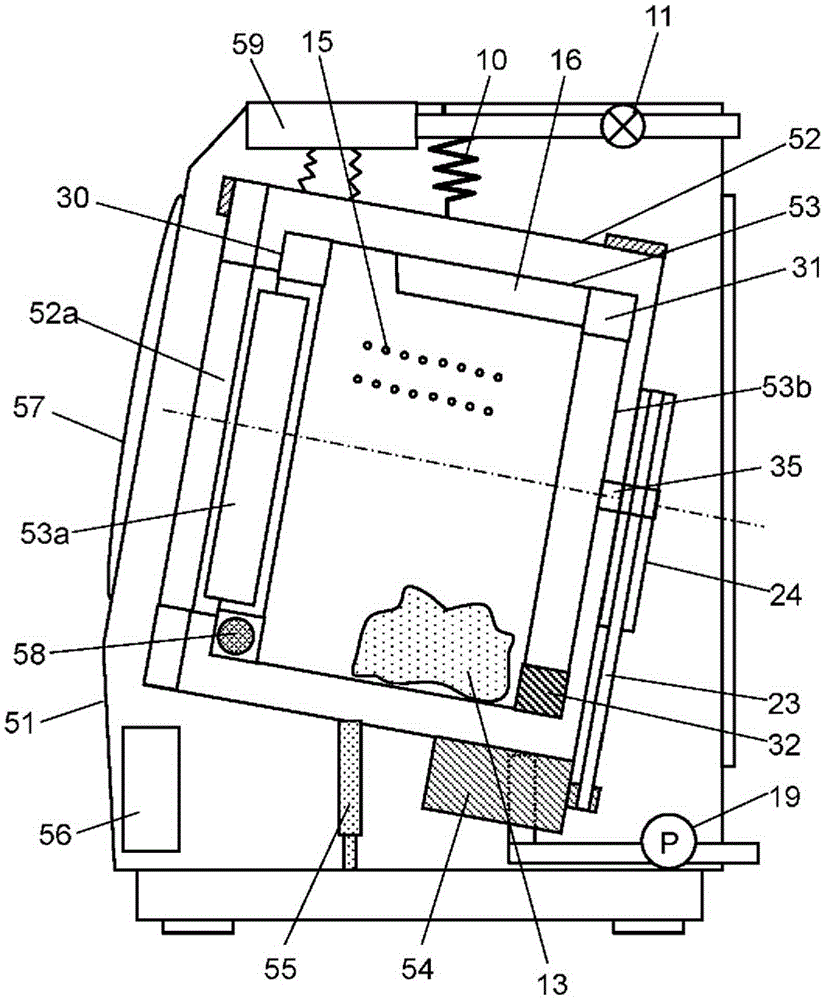

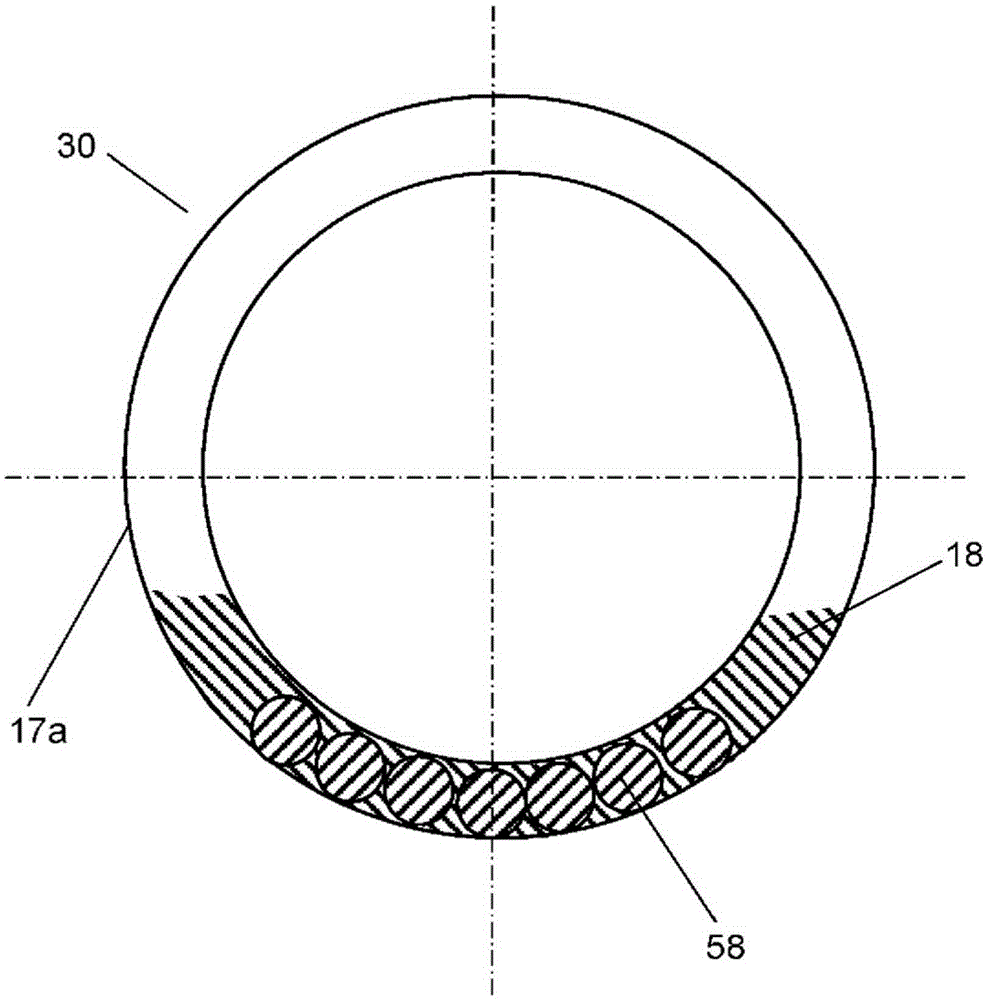

[0032] figure 1 It is a side sectional view of the drum-type washing machine 51 of Embodiment 1 of this invention. A bottomed cylindrical water tank 52 is housed inside the drum type washing machine 51. A bottomed cylindrical drum 53 is housed in the water tank 52. On the front side of the drum-type washing machine 51 where the laundry is inserted (in figure 1 The upper side is the left side) A door 57 is provided in a freely opening and closing manner. The drum 53 is provided with a drum opening 53a communicating with the inside of the drum 53 through the water tank opening 52a of the water tank 52. The drum 53 has a rotating shaft 35 that rotatably supports the drum 53 on the drum bottom surface 53b. The drum 53 is arranged obliquely so that the bottom side is lower than the front side. The water tank 52 is also arranged obliquely along the drum 53. By inclining the drum 53, the drum opening 53a is arranged to face diagonally upward. Therefore, the user can take out the ...

Embodiment approach 2

[0056] Next, a drum-type washing machine 61 according to Embodiment 2 of the present invention will be described. Figure 5 It is a side sectional view of the drum-type washing machine 61 of Embodiment 2 of this invention. Among the components of the drum-type washing machine 61, the same components as those of the drum-type washing machine 51 of the first embodiment are assigned the same reference numerals as those of the first embodiment, and the description thereof will be omitted.

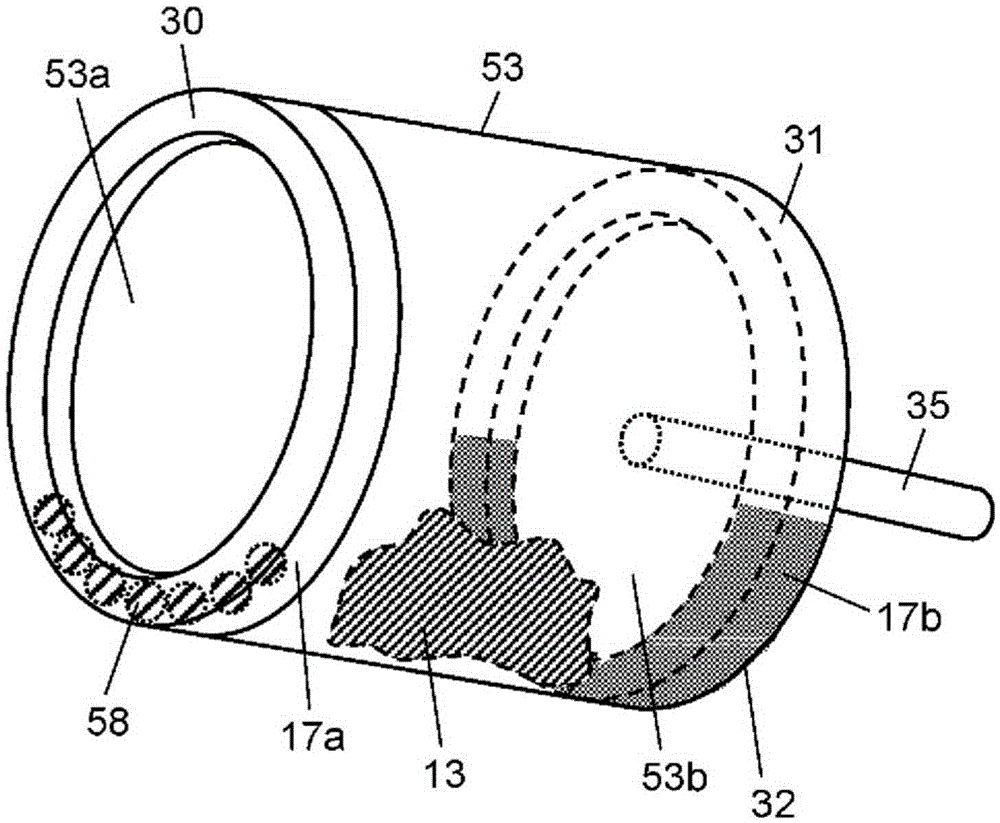

[0057] Image 6 It is a perspective view of the drum 53 of the drum-type washing machine 61 of Embodiment 2 of this invention. Image 6 Shows the state where the rotation is stopped.

[0058] In the second embodiment, a ball balancer 30 (first balancer) is provided in the vicinity of the drum end peripheral portion on the drum opening 53a side. A ball balancer 62 (second balancer) is provided near the drum end circumference on the drum bottom surface 53b side. As described below, these two ball bal...

Embodiment approach 3

[0068] Next, a drum-type washing machine 71 according to Embodiment 3 of the present invention will be described. Figure 8 It is a side sectional view of the drum-type washing machine 71 of Embodiment 3 of this invention. Among the components of the drum-type washing machine 71, the same components as those of the drum-type washing machine 51 of the first embodiment are assigned the same reference numerals as those of the first embodiment, and the description thereof is omitted.

[0069] Picture 9 It is a perspective view of the drum 53 of the drum-type washing machine 71 of Embodiment 3 of this invention. Picture 9 Shows the state where the rotation is stopped.

[0070] In the third embodiment, a ball balancer 72 (second balancer) is provided near the drum end peripheral portion on the drum bottom plate 53b side. A fluid balancer 73 (first balancer) is provided near the drum end circumference on the drum opening 53a side. These balancers are formed by accommodating heavy objec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com