Fixing and protecting device used when dust collector is transported

A technology for fixed protection and vacuum cleaners, which is applied in the direction of vacuum cleaners, cleaning equipment, household appliances, etc. It can solve the problems of brittle and easy to break protection pads, unable to support and protect vacuum cleaners, etc., and achieve the effect of reducing contact damage, avoiding damage, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiment.

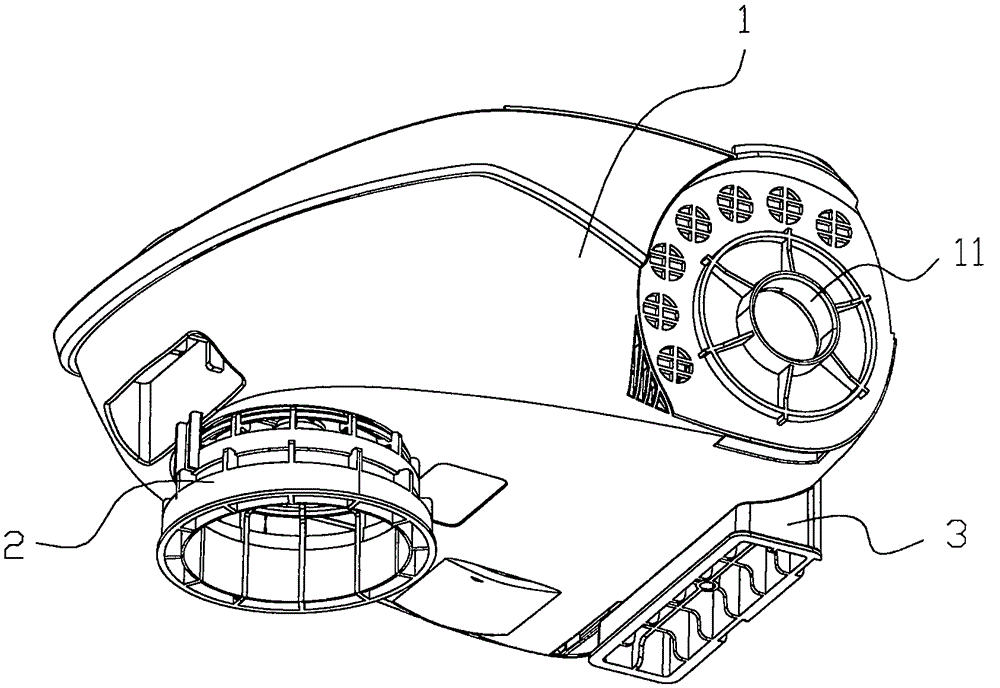

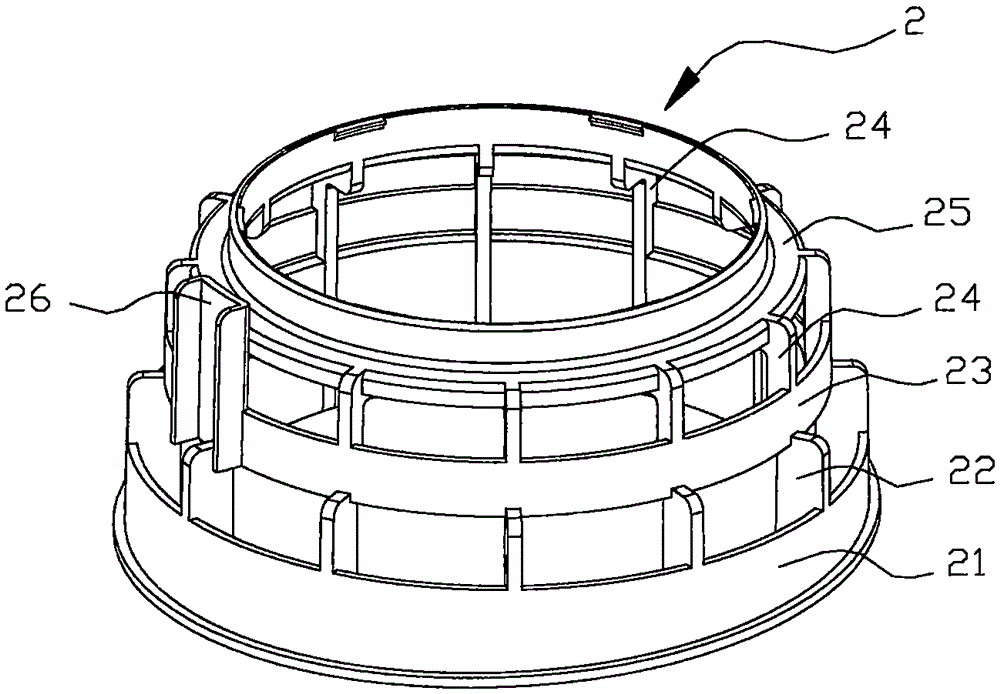

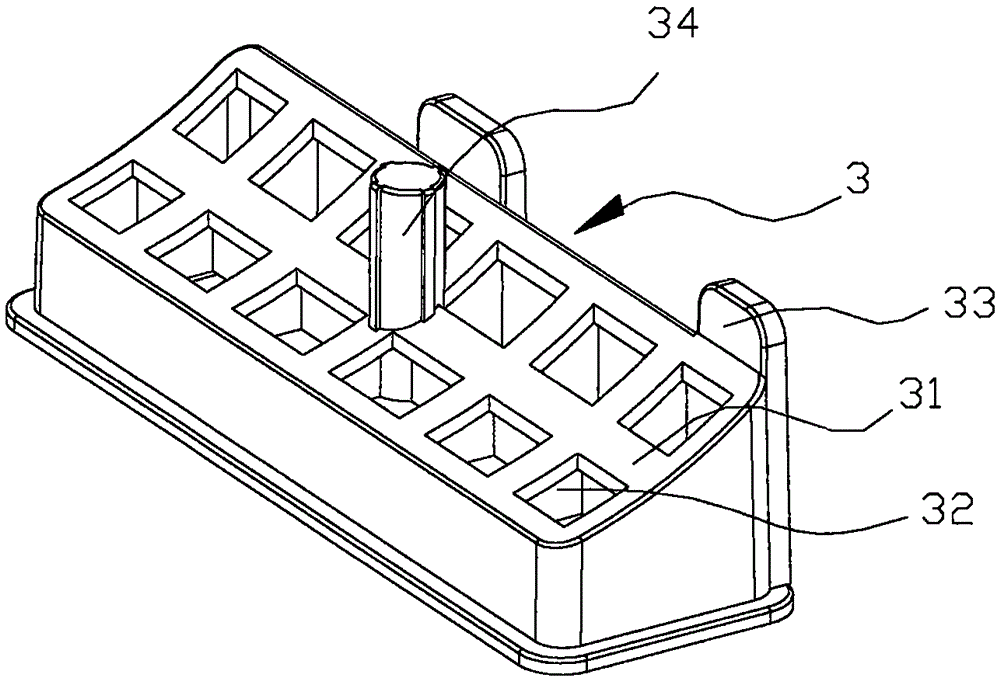

[0017] A fixed protection device for vacuum cleaner transportation according to the present invention is as follows: figure 1 , 2 , 3, including: a support ring 2 supporting the front portion of the vacuum cleaner 1 and a support base 3 supporting the rear portion of the vacuum cleaner, the rear portion of the vacuum cleaner 1 is provided with a shaft hole 11 for a traveling wheel, and the traveling wheel (not shown) is provided At the position corresponding to the shaft hole 11; the support ring 2 is made of elastic plastic integrally formed into a ring structure, consisting of three layers of rings connected axially by the bottom support ring 21, the middle support ring 23 and the upper support ring 25 , the bottom supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com