Press-forming tool with tolerance compensation

A stamping forming and mold technology, applied in the direction of presses, forming tools, manufacturing tools, etc., can solve the problems of small cooling rate, cooling performance decline, etc., and achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

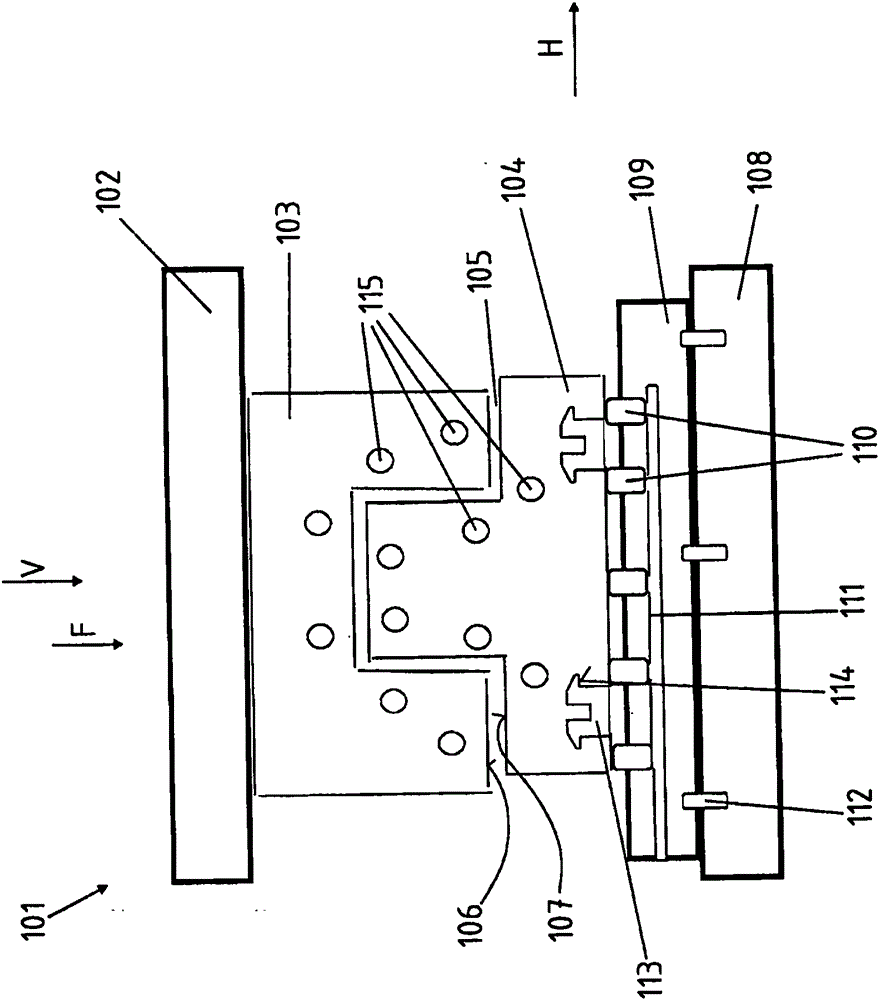

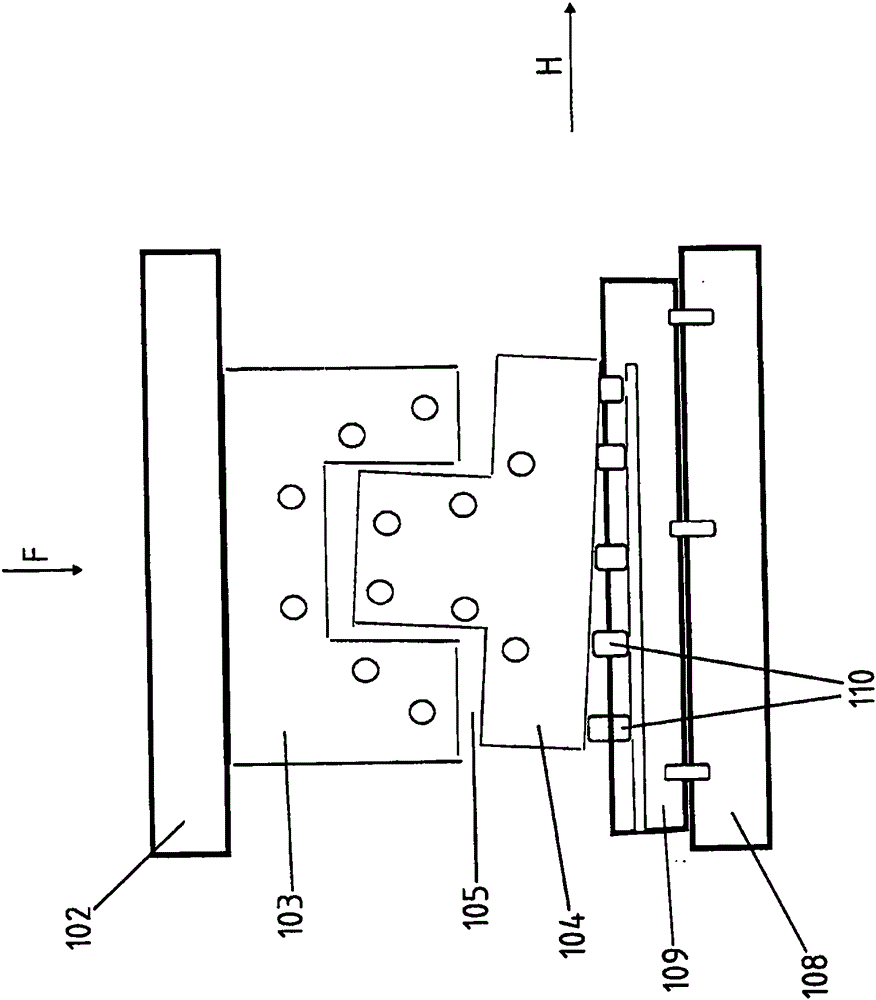

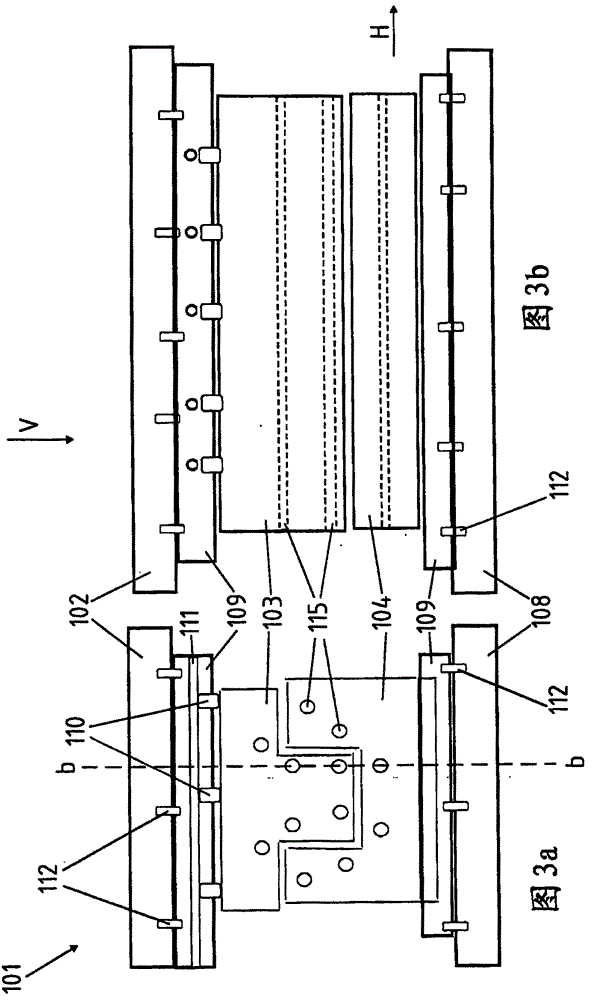

[0035] figure 1 A lateral cross-sectional view of the stamping mold 101 according to the present invention is shown. For this purpose, the stamping mold 101 has a pressure punch 102 shown from top to bottom in the drawing plane, and an upper mold 103 not shown in detail is coupled with the pressure punch 102. The press punch 102 applies a pressing force F with respect to a vertical direction V and closes the upper die 103 and the lower die 104, which at the same time corresponds to the punching stroke movement. Between the upper mold 103 and the lower mold 104, an inter-mold gap 105 and a slab not shown in detail in the figure are retained. Within the scope of the present invention, the slab is particularly preferably fully attached to the corresponding mold surfaces 106, 107 . According to the present invention, a mold clamping plate 109 is provided on the punching table 108, and different elastic adjustment elements 110 are arranged between the lower mold 104 and the mold cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com