Secondary mold opening mechanism provided with drag hook

A technology of secondary mold opening and hook, applied in the field of metal die-casting, can solve the problems of damaged mold working parts, complex mold structure, inconvenient mold manufacturing, installation, debugging, and maintenance, etc., to achieve the effect of simple structure and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below by means of specific embodiments:

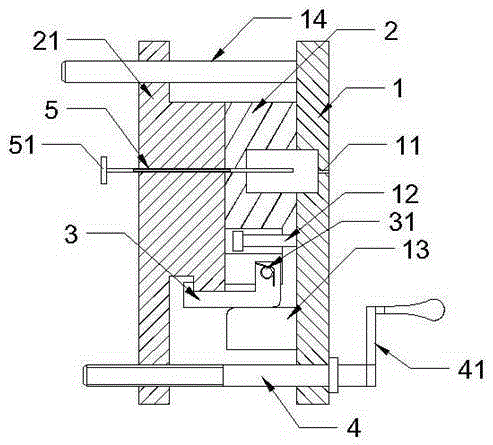

[0012] The reference signs in the drawings of the description include: fixed die 1, perforation 11, guide rod 12, limit block 13, limit rod 14, first movable die 2, second movable die 21, pull hook 3, torsion spring 31 , screw rod 4, hand wheel 41, core rod 5, handle 51.

[0013] The embodiment is basically as attached figure 1 Shown:

[0014] The secondary mold opening mechanism with pull hooks in this solution includes a movable mold and a fixed mold 1. The fixed mold 1 and the movable mold fit together to form a mold cavity inside. The fixed mold 1 is provided with a perforation 11 communicating with the mold cavity. The movable mold includes a first movable mold 2 and a second movable mold 21 , and a core rod 5 connected to the second movable mold 21 is arranged in the mold cavity.

[0015] A drag hook 3 is hinged on the first movable mold 2, a torsion spring 31 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com