Cutting torch pendulum angle conversion device

A technology for converting devices and swing angles, applied in auxiliary devices, welding/cutting auxiliary equipment, gas flame welding equipment, etc., can solve the problems of heavy overall weight, inclination angle error, high rotation load, etc., to improve operating efficiency and meet Technical requirements, high stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

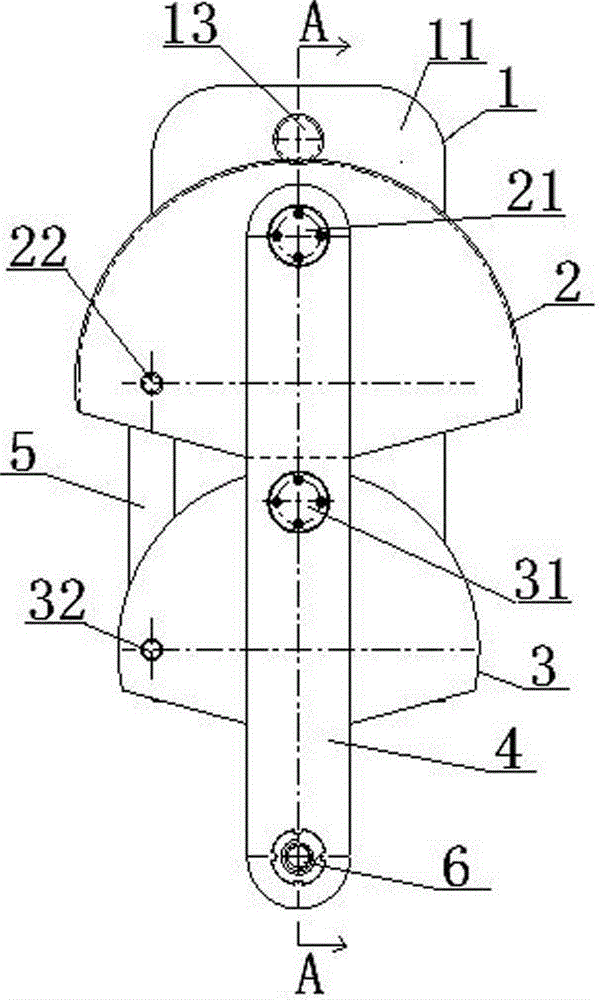

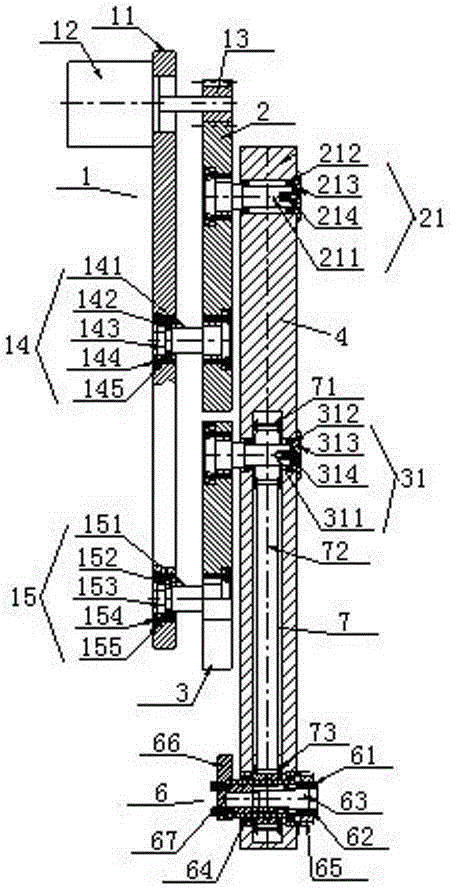

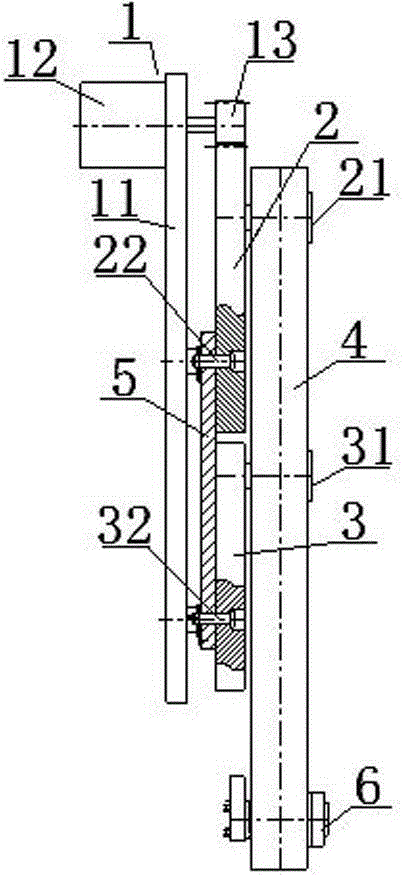

[0024] see figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention is a cutting torch swing angle conversion device, which includes a base frame 1, a driving wheel 2, a driven wheel 3, a first connecting rod 4, a second connecting rod 5, a clamping mechanism 6 and a synchronous mechanism 7.

[0025] Wherein, the base frame 1 has an upright base board 11 . Servomotor 12 (at the top of base plate 11), second shaft assembly 14 (at the middle of base plate 11) and fourth shaft assembly 15 (at The lower part of the base plate 11 ), the servo motor 12 , the second shaft assembly 14 and the fourth shaft assembly 15 are basically arranged on the same vertical line of the base plate 11 (hereinafter referred to as the baseline). The servomotor 12 is fixed on the back side of the base plate 11, the output shaft of the servo motor 12 passes through the base plate 11, and protrudes on the front of the base plate 11, and the output shaft of the servo motor 12 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com