Efficient numerical control machining method for thin and long beam type parts

A processing method and parts technology, applied in the field of high-efficiency numerical control processing, can solve the problems of adding auxiliary heat treatment process, difficult processing, and affecting the service life of aircraft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

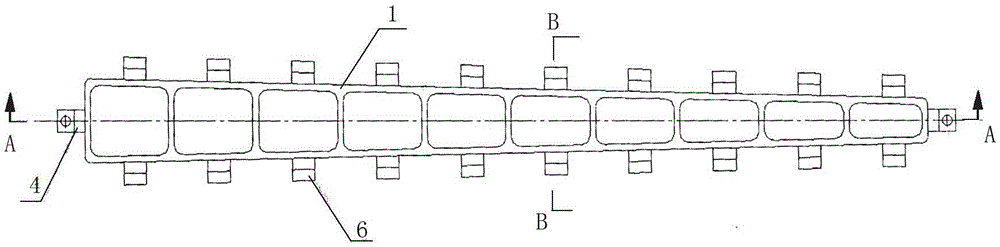

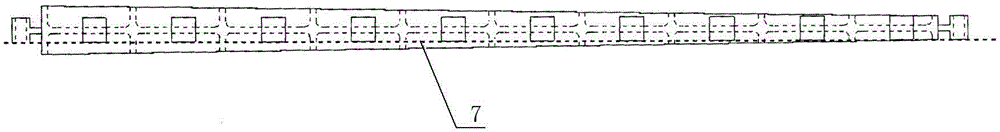

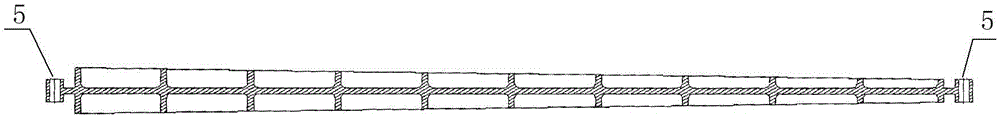

[0026] Such as Figure 1 to Figure 4 As shown, a high-efficiency CNC machining method for slender beam parts includes the following steps:

[0027] 1) Analyze the material information of the parts, the state of the wool and the structural characteristics, and select the CNC machine tool;

[0028] 2) Set the rough and finish machining process plan, set the front side of the part as side A, and set the back side as side B;

[0029] 2.1) Milling datum positioning surface for straightening, alignment and fixed positioning;

[0030] 2.2) Drilling process holes, milling out several process bosses, the process bosses are arranged symmetrically along the axial direction of slender beam parts;

[0031] 2.3) Use the pressure plate to fix all the process bosses, rough machine the A surface of the part, and process it from the blank to a margin of 7.0mm;

[0032] 2.4) Turn the part over, fix all the process bosses with the pressure plate, rough machine the B side, and process it from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com