An electromagnetic field-assisted diffusion connection device and method for a glass plate and a metal plate

A technology of diffusion connection and glass plate, which is applied in the field of connection of dissimilar materials, can solve the problems of inability to realize connection and inability to diffuse and move ions, and achieve the effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

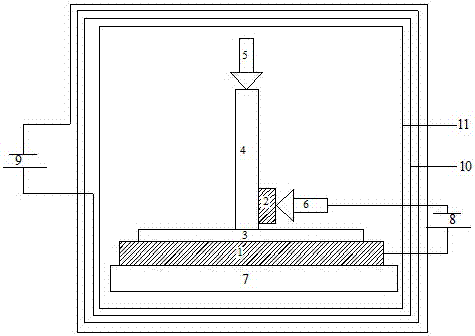

[0028] This embodiment provides a glass plate-Kvar alloy plate diffusion connection.

[0029] Both the Kovar plate and the glass plate are square plates with a thickness of 2mm and a length of 40mm, and the glass composition: 5.0%Na 2 O, 3.6% B 2 o 3 , 4.2% Al 2 o 3 , 2.5%K 2 O, the rest are SiO 2 , the bonded surface of the glass plate and Kovar alloy plate is ground and polished, the surface roughness is less than 1μm, the electrode plate in contact with the glass has a length of 40mm, according to figure 1 Put the Kovar plate and the glass plate in the bonding furnace in the manner shown, heat the furnace to 400°C, turn on the high-voltage DC power supply and the low-voltage DC power supply, apply a DC voltage of 900V to the sample, and adjust the low-voltage power supply so that the magnetic field strength 0.5T, keep it for 5 minutes, turn off the heating power supply, high-voltage DC power supply and low-voltage DC power supply at the same time, and cool the sample...

Embodiment 2

[0032] This embodiment provides a glass plate-stainless steel plate diffusion connection.

[0033] Both the stainless steel plate and the glass plate are square plates with a thickness of 3mm and a length of 50mm, and the glass composition: 3.0%Na 2 O, 2.5% B 2 o 3 , 2.8% Al2 o 3 , 3%K 2 O, the rest are SiO 2 , the bonding surface of the glass plate and the Kovar alloy plate has been ground and polished, and the surface roughness is less than 1 μm. The electrode plate in contact with the glass has a width of 2.5 mm and a length of 50 mm. figure 1 Place the Kovar alloy plate and the glass plate in the bonding furnace in the manner shown, heat the furnace to 400°C, turn on the high-voltage DC power supply and the low-voltage DC power supply, apply a 600V DC voltage to the sample, and adjust the low-voltage power supply so that the magnetic field strength 1.0T, after keeping for 5 minutes, turn off the heating power supply, high-voltage DC power supply and low-voltage DC po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com