Low-gloss abs resin composition and preparation method thereof

A technology of ABS resin and composition, applied in the field of low-gloss ABS resin composition and preparation thereof, can solve the problems of deterioration of mechanical properties, insufficient gloss, uneven distribution, etc., and achieves improved compatibility, simple preparation process, Matte even and delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

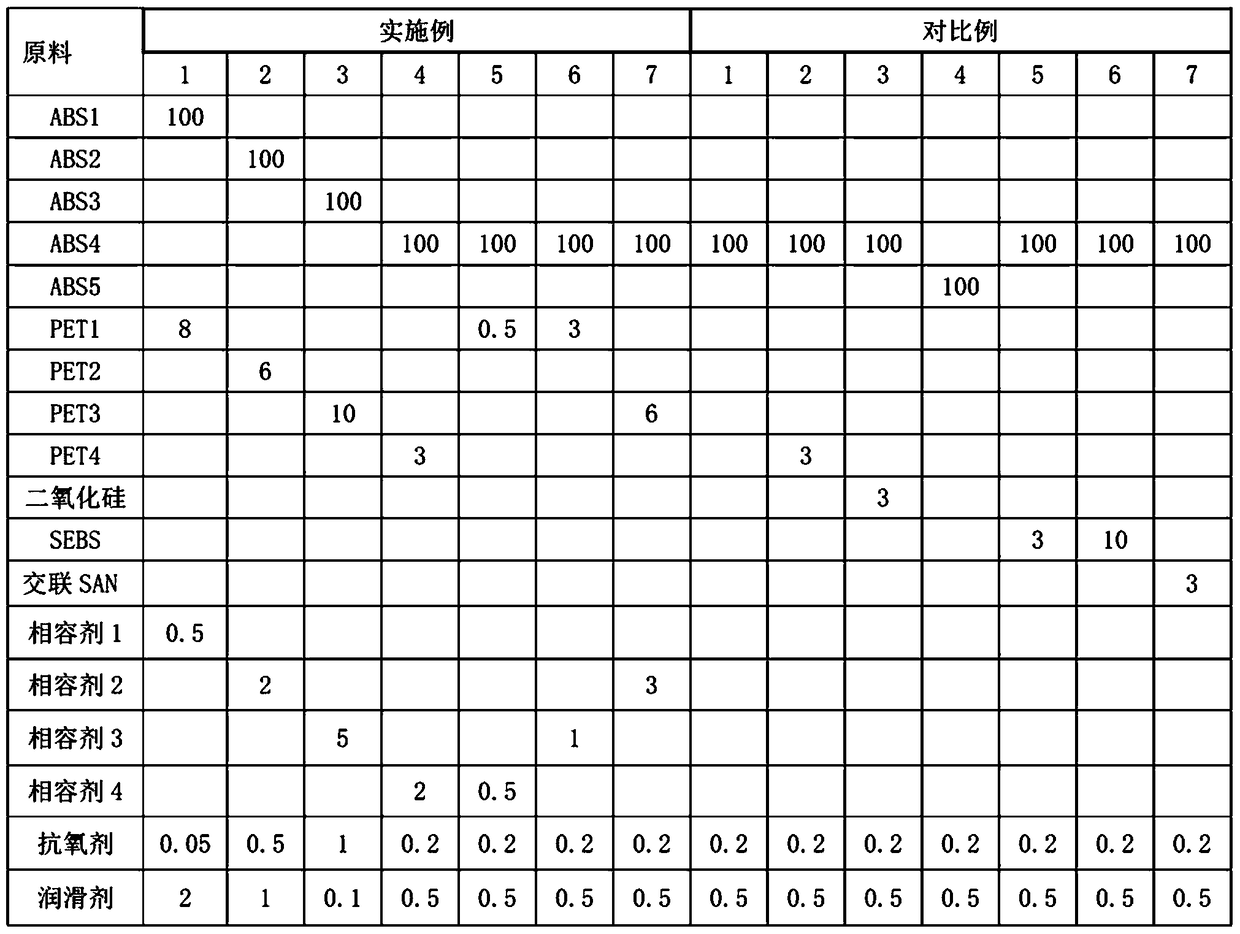

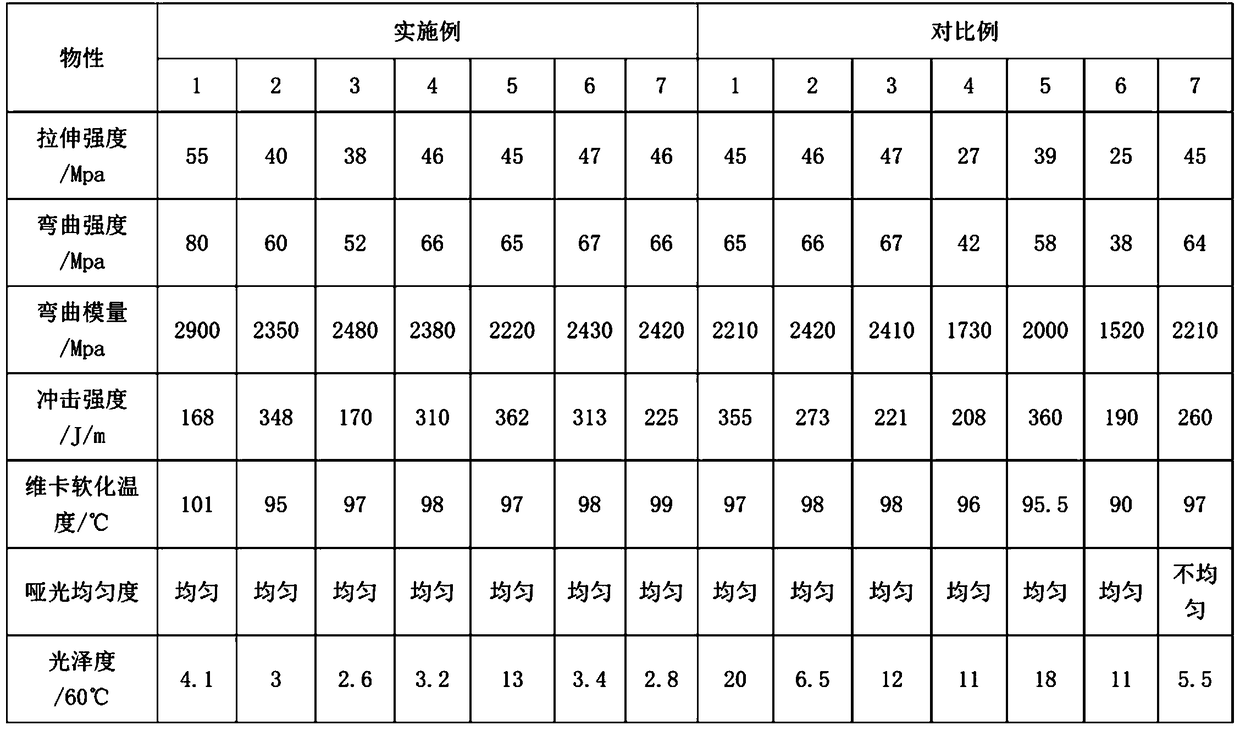

Embodiment 1~7 and comparative example 1~7

[0027] Each component and its content in the low-gloss ABS resin composition in Examples 1 to 7 and Comparative Examples 1 to 7 are shown in Table 1, and the materials are prepared according to the components and content of each Example and Comparative Example in Table 1 . First, the prepared material is fully stirred and premixed in a high-speed mixer for 3 to 10 minutes, and then the premixed material is passed through a twin-screw extruder at an extrusion temperature of 190 to 240 °C, and the screw speed is 200 to 600 rpm. Melt extrusion under the condition of 10 minutes, cooling and granulation to obtain the ABS resin composition with matte effect.

[0028] Involving component and characteristic in above embodiment and comparative example are as follows:

[0029] ABS1: butadiene rubber content 20%, number average particle size 0.2μm, weight average molecular weight 80,000;

[0030]ABS2: butadiene rubber content 16%, number average particle size 1.4μm, weight average mole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com