ABS (Acrylonitrile Butadiene Styrene) composite material with matte effect and preparation method thereof

A composite material and ABS resin technology, which is applied in the field of ABS composite material with matte effect and its preparation, can solve the problems of high energy consumption, uneven gloss distribution, performance deterioration, etc., achieve simple preparation process and improve matte performance , The effect of reducing the processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the ABS composite material with matte effect comprises the following steps:

[0030] The ABS resin, the matte powder, and the antioxidant are weighed according to the formula, and premixed in a high-speed mixer for 5-10 minutes to obtain a premix;

[0031] The premixed material is added to a twin-screw extruder for extrusion and granulation to obtain an ABS composite material with a matte effect.

[0032] Further, the temperature setting of the twin-screw extruder is: 160-180°C in the first zone, 180-190°C in the second zone, 180-190°C in the third zone, 180-190°C in the fourth zone, 180-190°C in the fifth zone, The sixth zone is 180-190°C, the seventh zone is 180-190°C, the eighth zone is 180-190°C, the ninth zone is 180-190°C, the tenth zone is 180-190°C, and the machine head is 190-200°C.

[0033] Further, the rotational speed of the screw is 300-400r / min, and the screw aspect ratio of the twin-screw extruder is 40-52.

[0034] Further, in...

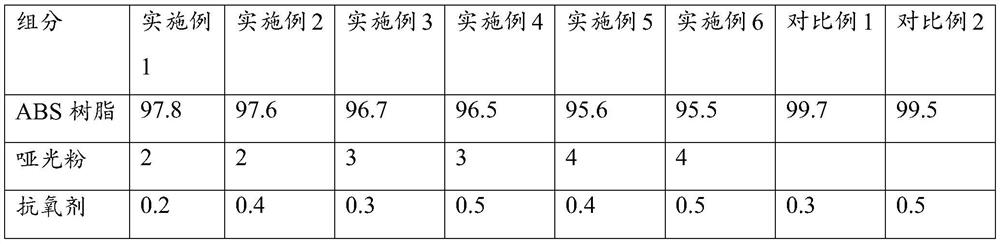

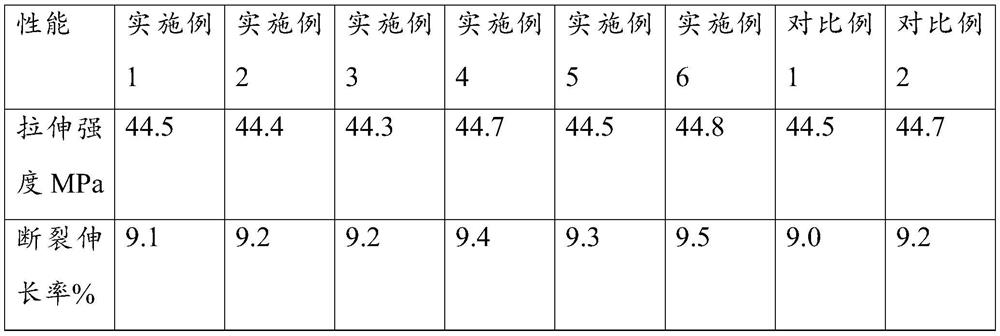

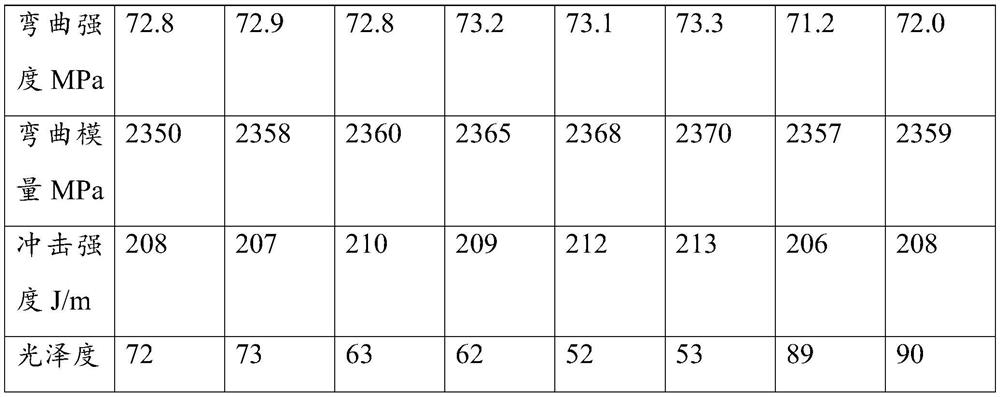

Embodiment 1-6 and comparative example 1-2

[0036] The formulations (unit: %) of the ABS composite materials in Examples 1-6 and Comparative Examples 1-2 are shown in the table below. Prepare materials according to the components and contents of each embodiment and comparative example in Table 1; fully stir and premix the prepared materials in a high-speed mixer, and in a preferred embodiment, premix for 8 minutes; finally add the premix ABS composite material can be obtained by extruding and granulating with twin-screw extruder. The preparation process of the ABS composite material of the invention is simple, and the existing equipment can be used for mass production.

[0037] In the above example, the temperature setting of the twin-screw extruder is: 170°C in the first zone, 185°C in the second zone, 185°C in the third zone, 180-190°C in the fourth zone, 185°C in the fifth zone, 185°C in the sixth zone, The seventh zone is 185°C, the eighth zone is 185°C, the ninth zone is 185°C, the tenth zone is 190°C, and the mac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com