Lithium electric copper foil anti-oxidization liquid and anti-oxidization treatment technology

An anti-oxidation solution and anti-oxidation technology, which is applied in the direction of electrolytic organic material coating, etc., can solve the problems of wastewater discharge, copper foil production cost increase, unfavorable environmental protection and enterprise development, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]

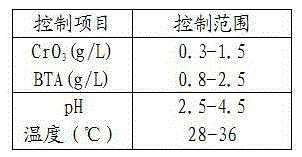

[0024] Table 1 Process parameters of lithium battery copper foil anti-oxidation solution

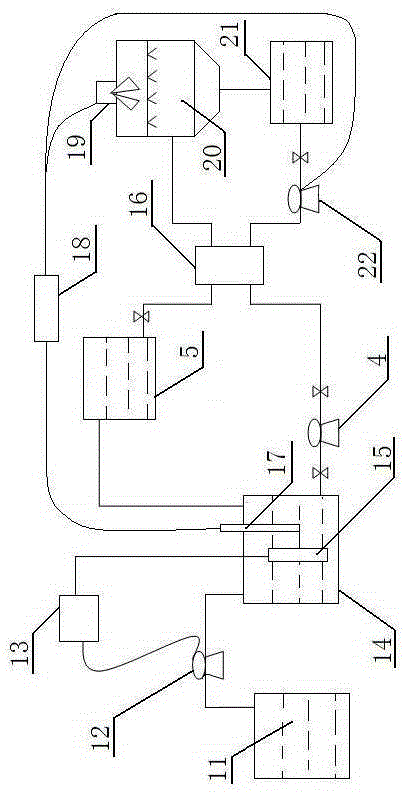

[0025] At the same time, the online anti-oxidation treatment process conditions generally include the contents shown in Table 2:

[0026]

[0027] Table 2 Process parameters of lithium battery copper foil anti-oxidation solution

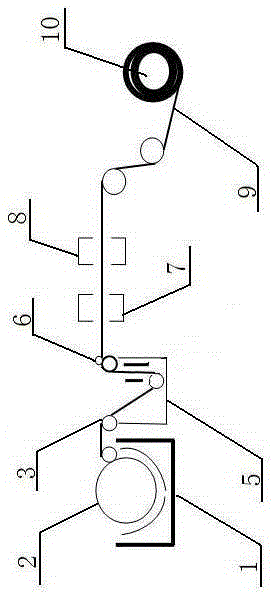

[0028] like figure 1 As shown, the second part is that after the lithium battery copper foil 9 is peeled off from the raw foil machine 1, it enters the anti-oxidation electroplating tank 5 filled with anti-oxidation solution through the guide roller 3, and performs electroplating and anti-oxidation treatment according to the online anti-oxidation treatment process conditions. After that, it passes through squeeze roll 6, bellows 7, oven 8, and copper foil winding roll 10. Lithium battery copper foil anti-oxidation treatment is an online continuous completion.

[0029] During the production process, the pH value of the lithium battery copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com