Precast segment assembled concrete filled steel tube bridge pier based on bolted connection

A technology of concrete-filled steel tubes and prefabricated steel tubes, applied in bridges, bridge parts, bridge materials, etc., can solve problems such as damage and large residual displacement, and achieve the effects of reducing traffic delays, convenient construction, and strong shear bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

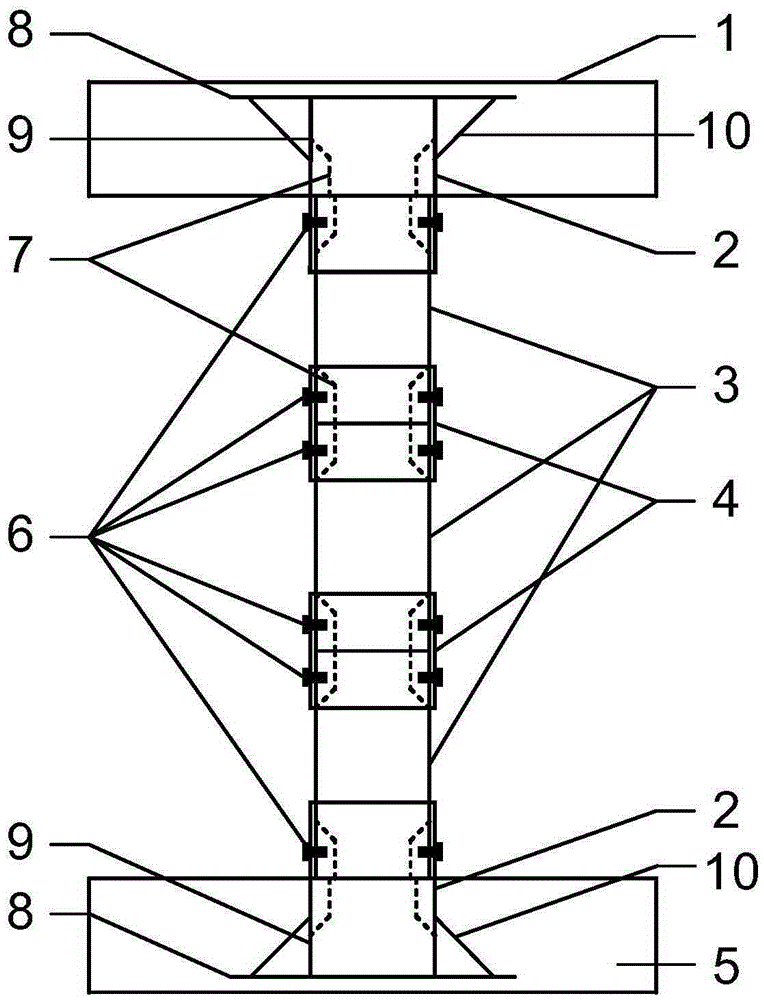

[0030] Step 1: Process node pre-embedded steel connector 2, steel pipe concrete segment 3, and connecting steel pipe 4 between segments, specifically including the following steps:

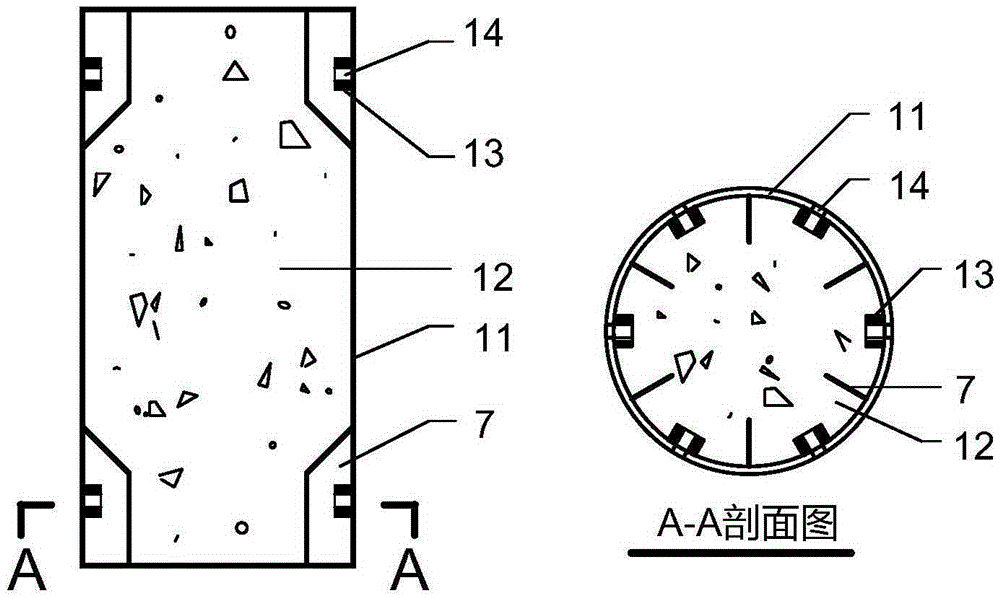

[0031] 1) Fabricate the steel pipe concrete section 3, manufacture the steel pipe concrete section 3 in the factory, weld the inner stiffeners 7 to both ends of the steel pipe section 11, process reserved bolt holes at both ends, connect the preset nuts with the reserved After the axis of the bolt hole is aligned, it is spot welded and fixed, and the concrete is poured for curing;

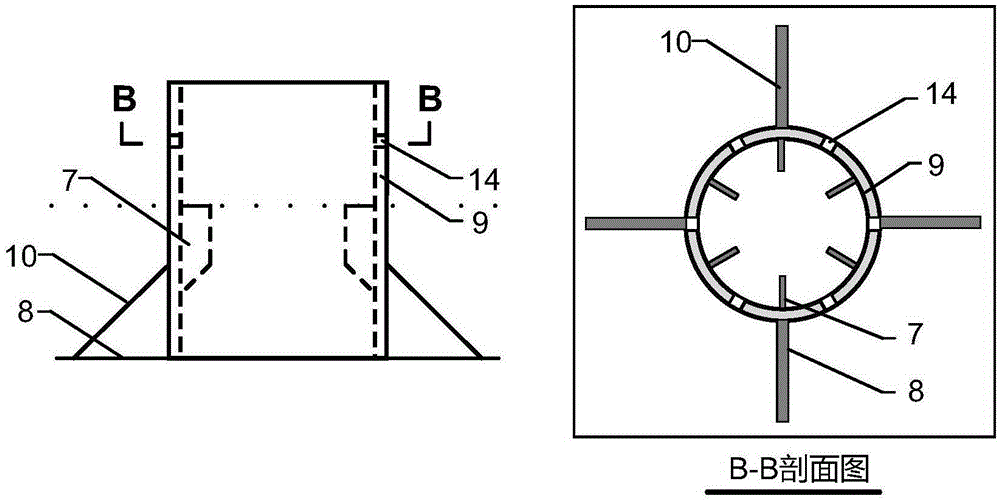

[0032] 2) Make the node pre-embedded steel connector 2, make the node pre-embedded steel connector in the factory, weld the inner stiffener 7, the end welded steel plate 8 and the outer stiffener 10, and process the reserved bolt hole 13;

[0033] 3) Make the inter-segment connecting steel pipe 4, make the inter-segment connecting steel pipe in the factory, and process the reserved bolt holes 13;

[0034] Step 2: Asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com