FRP wrapped recycled concrete composite tubular pile

A technology of recycled concrete and combined pipes, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering. It can solve the problems of increasing workload and construction costs, consuming steel molds or wooden molds, and achieving the elimination of formwork and saving steel. Model, the effect of speeding up the construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

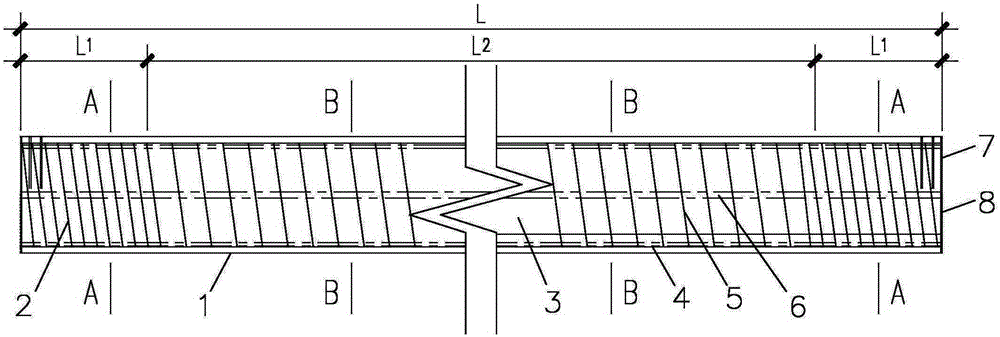

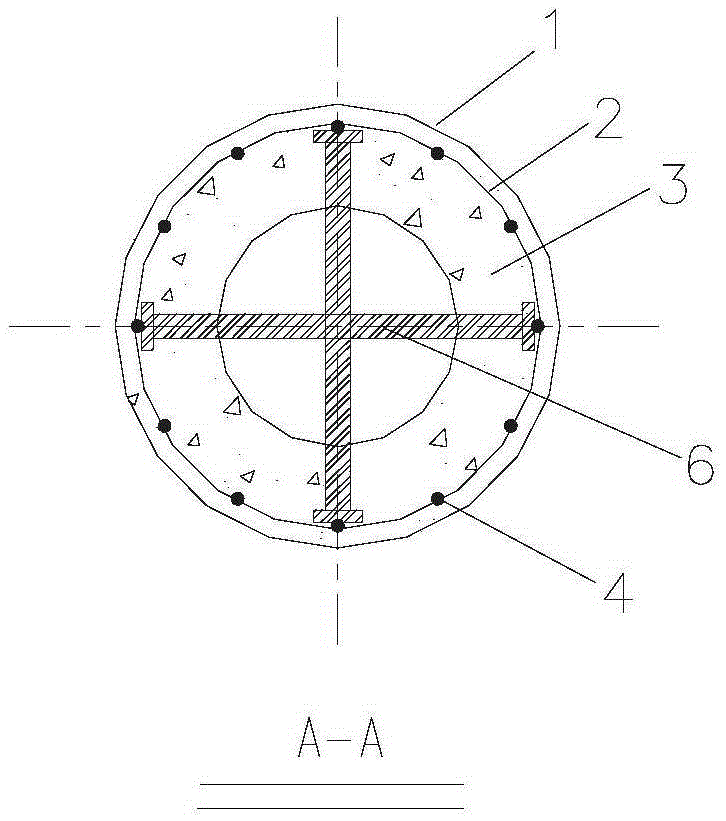

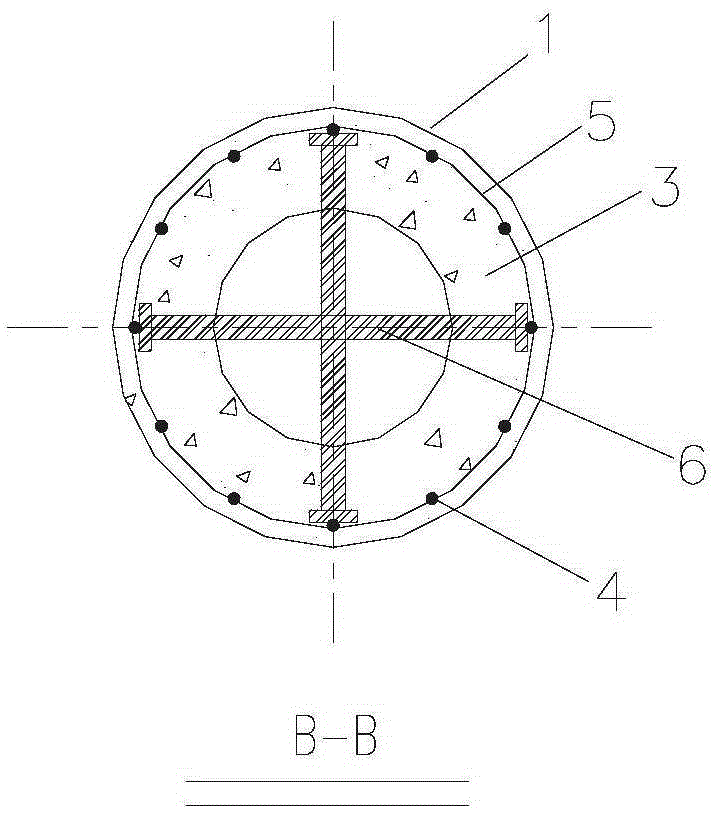

[0024] like Figures 1 to 4 As shown, the present invention outsources FRP recycled concrete composite pipe pile (outer diameter is 400mm, wall thickness 95mm, length is 9m), mainly is made of FRP pipe 1, circular reinforcement cage skeleton, cross-shaped steel frame 6 and recycled concrete, The circular steel cage skeleton and cross-shaped steel frame are placed in the FRP pipe (that is, the FRP pipe is outsourced with longitudinal steel bars, spiral stirrups, and cross-shaped steel frame), and recycled concrete 3 is poured in the tube, and the recycled concrete is made along the surrounding surface of the FRP pipe by centrifugal technology. Uniform and dense, so that the recycled concrete forms a circular cavity in the FRP pipe. in,

[0025] The FRP pipe is spliced by two upper and lower semicircular FRP pipes, with an outer diameter of 400mm and a wall thickness of 5mm, and the interface is sealed and glued with FRP adhesive.

[0026] The circular steel cage frame is we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com