Special lifting anti-falling machine for three-dimensional centered steel single-guide-rail and double-screw attached scaffold

A technology of double screw rod and single guide rail is applied in the direction of scaffolding supported by housing structure, housing structure support, housing structure support, etc., which can solve the problems of difficult disassembly, high cost and complex structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

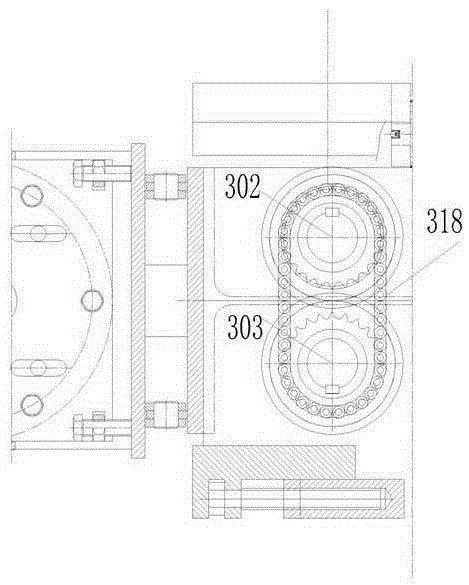

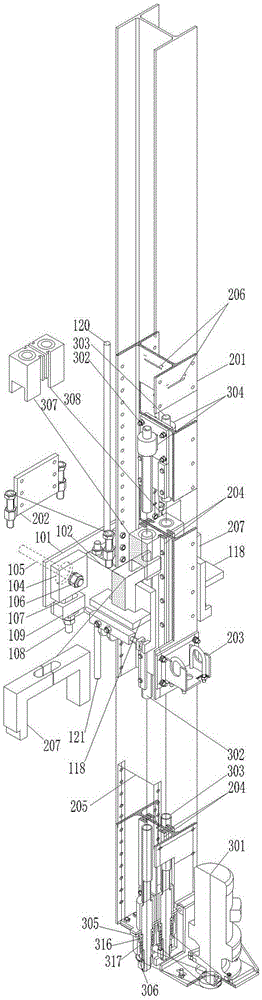

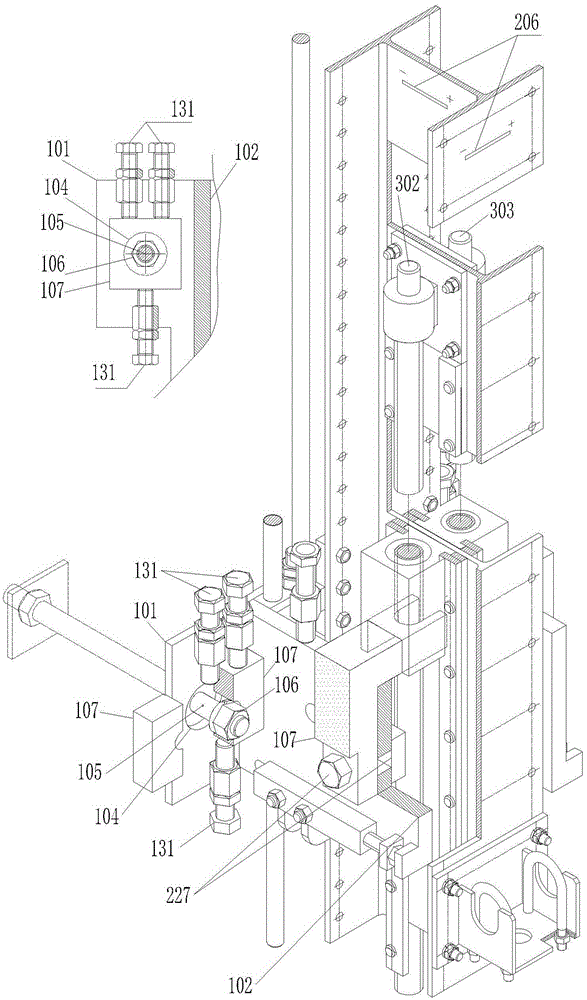

[0054] Example: Such as Figure 1 to Figure 20 As shown, the three-dimensional centered steel single guide rail double screw rod attached scaffolding special lifting anti-falling machine of the present invention is equipped with a three-dimensional deviation correction centering interconnection wall support device, a steel single track deflection warning device and double screw rods in the track. Composed of spiral lifting and anti-falling devices; three-dimensional correction centering installation interconnection wall support device consists of wall-mounted plate 101, cantilever plate 102, horizontal plate 103, wall-through bolt 105, wall-through bolt nut 106, wall-through bolt nut Large backing plate 107, backing plate bolt 108, rectangular pipe seat 109, guide wheel 112, helical distance adjustment slider 113, anti-overturning roller 114, anti-overturning roller stepped shaft 115, pin seat 118, upper connecting twin screws 120, lower connecting Composed of double screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com