Method and system for automatically placing aged lamp tube onto production line based on visual positioning

A visual positioning and assembly line technology, applied in the field of automatic placement of aging pipeline lamps, can solve the problems of aging lamp holder deviation, lamp pin lamp tube body damage, limit structure error, etc., to overcome position deviation and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

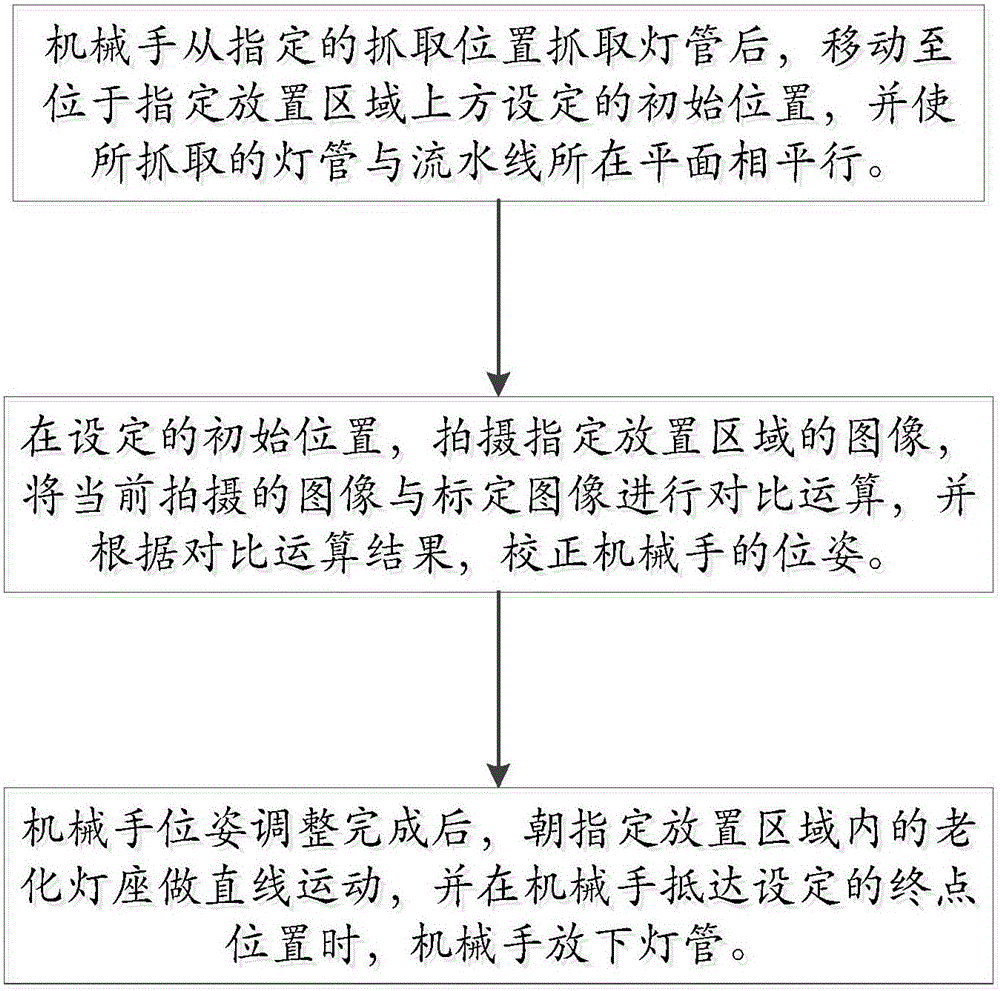

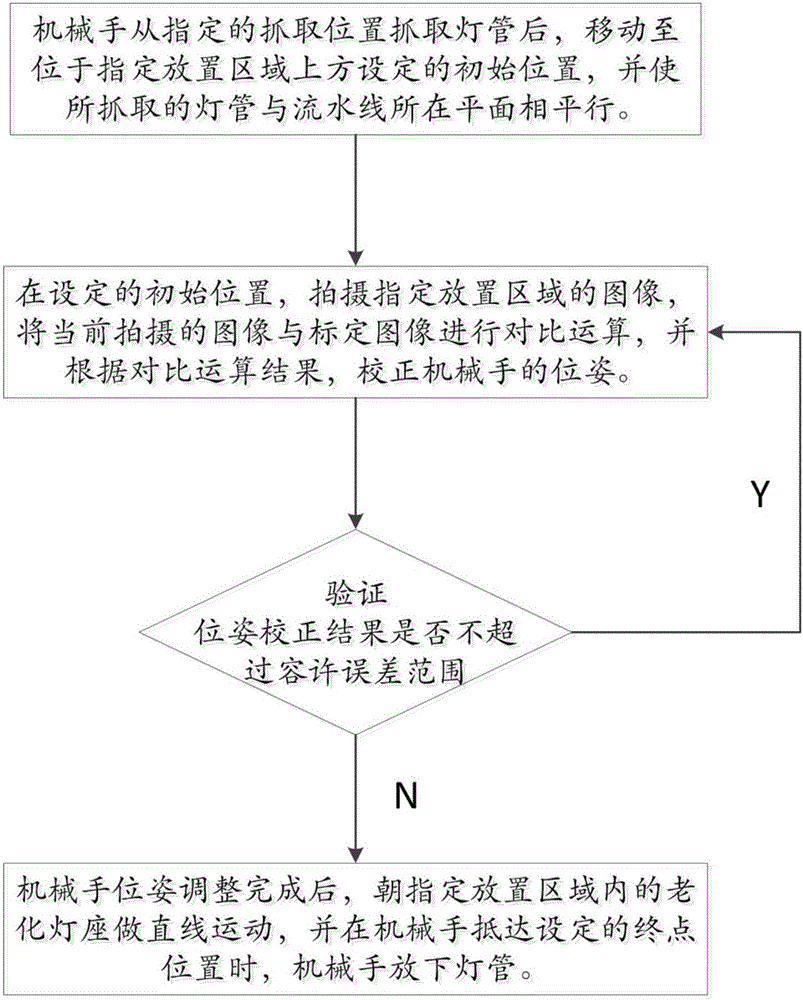

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in combination with specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

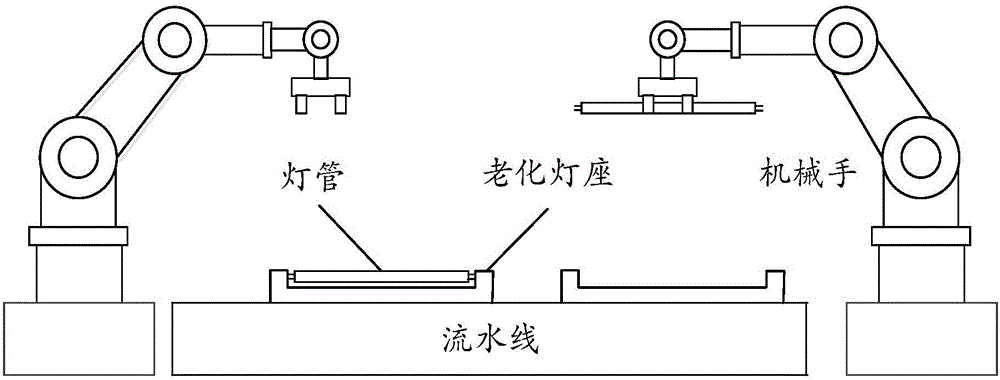

[0029] combine figure 1 The schematic diagram of the lamp aging assembly line is shown; wherein, the aging lamp holders are arranged on the assembly line at equal intervals, and the two ends of the aging lamp holders are provided with connecting terminals electrically connected to the lamp tubes. Whenever the manipulator places the lamp tubes After reaching the current aging lamp socket, the control system of the assembly line will obtain a trigger signal, and accordingly control the assembly line to push the next vacant aging lamp socket to the designated placement area. The lamp tube put into the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com