Casing type silencer

A kind of muffler and casing type technology, applied in the direction of sound absorption, muffler device, machine/engine, etc., can solve the problem of limited muffler effect, etc., to achieve the effect of noise elimination and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

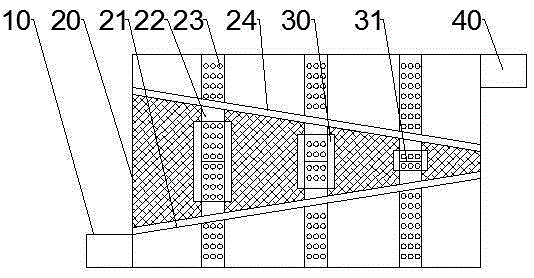

[0018] Such as figure 1 As shown, the sleeve type muffler has a scheme as follows: it includes a housing 20, one end of the housing 20 is connected to the intake pipe 10, the other end of the housing 20 is connected to the outlet pipe 40, and the housing 20 is provided with a first partition 21 and a second partition Plate 24, the first and second partitions divide the inside of the housing 20 into three chambers: upper, middle and lower chambers. The first partition 21 is arranged obliquely upward from the direction of the inlet pipe 10 to the outlet pipe 40, and the second partition 24 is formed by The direction from the air outlet pipe 40 to the air inlet pipe 10 is arranged obliquely upward, and a vertical air guide pipe 22 is also provided in the housing 20. The air guide pipe 22 is uniformly arranged in an array on the bottom surface of the housing 20, and the air guide pipe 22 is arranged in the upper and lower chambers. The indoor part is provided with a ventilation ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com