Cooling suite of LED project lamp

A technology for LED flood light and flood light, which is applied to semiconductor devices of light-emitting elements, parts of lighting devices, cooling/heating devices of lighting devices, etc. Complicated and other problems, to achieve the effect of beautiful and tidy appearance, remarkable heat dissipation effect, and overall smooth and uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

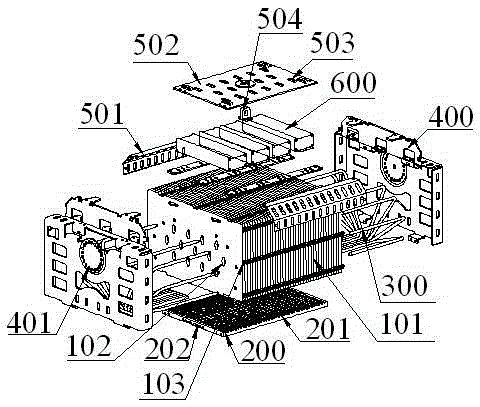

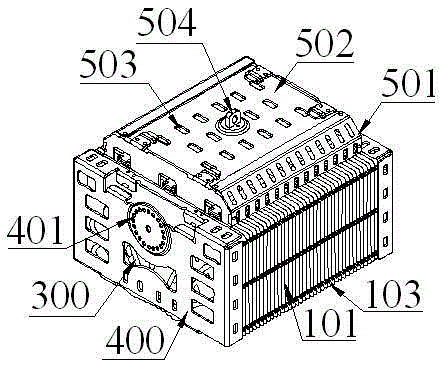

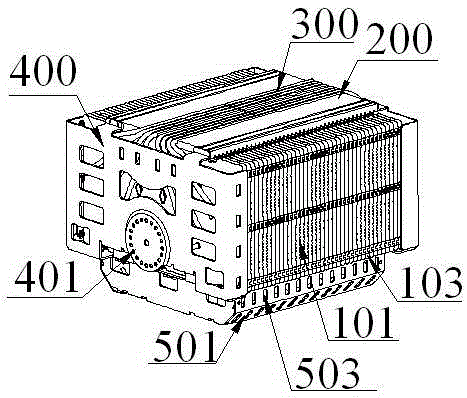

[0022] refer to Figure 1 to Figure 6 , an embodiment of the heat dissipation kit of the LED floodlight of the present invention is proposed, which can be fixedly connected with the LED illuminant, including a heat dissipation module and a driving device 600 fixed on the heat dissipation module and electrically connected to the LED illuminant. The illuminant is fixed on the lower end surface of the heat dissipation module.

[0023] The heat dissipation module includes a heat dissipation fin module, a metal heat conduction plate 200, a number of heat pipes 300 embedded in the metal heat conduction plate 200 and interspersed in the heat dissipation fin module with superconducting heat capacity, and located on the heat dissipation fin module. The mounting side plates 400 on both sides and protecting the heat pipe 300 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com