Direct-current wind tunnel device and working method thereof

A wind tunnel and airflow technology, applied in the direction of measuring devices, instruments, aerodynamic tests, etc., can solve the problems of high equipment requirements, short explosion time, and large power grid pressure, and achieve the effect of simplified wind tunnel structure and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

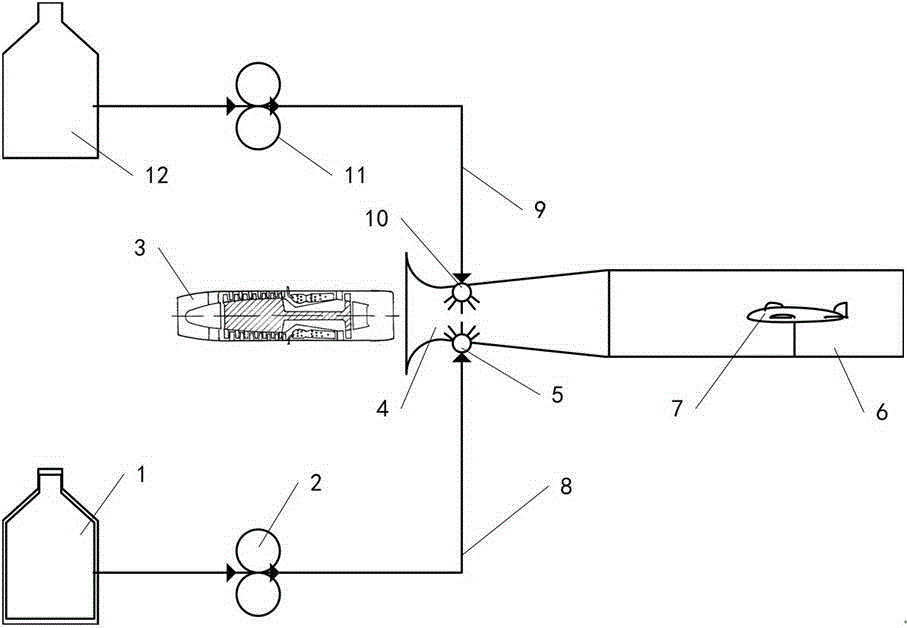

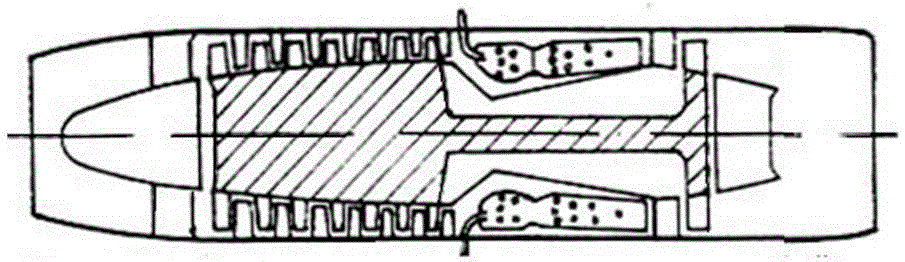

[0018] In this example, refer to Figure 1 to Figure 2 As shown, a DC wind tunnel device includes a liquid air storage tank 1, a cryopump 2 connected to the liquid air storage tank 1, a liquid air pipeline 8 connected to the cryopump 2, and a liquid air pipeline 8 The connected liquid air atomizing nozzle 5, and the water atomizing nozzle 10 arranged on one side of the liquid air atomizing nozzle 5, and the water pipeline 9 connected with the water atomizing nozzle 10, and the liquid pump 11 connected with the water pipeline 9 , and the water storage tank 12 that is connected with the liquid pump 11, and the mixing stabilization section 4 fixed on one end of the liquid air atomizing nozzle 5 and the water atomizing nozzle 10, and the other with the liquid air atomizing nozzle 5 and the water atomizing nozzle 10 The test section 6 connected at one end, the test model 7 arranged in the test section 6, and the jet engine 3 arranged on one side of the mixing and stabilizing sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com