Dynamo-electric machine with reluctance and permanent magnet rotor

A rotor and machine technology, applied in the direction of electromechanical devices, magnetic circuit rotating parts, magnetic circuits, etc., can solve the problems of high torque fluctuation, low power density, etc., and achieve small torque fluctuation, high power density, high critical rotational speed moment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

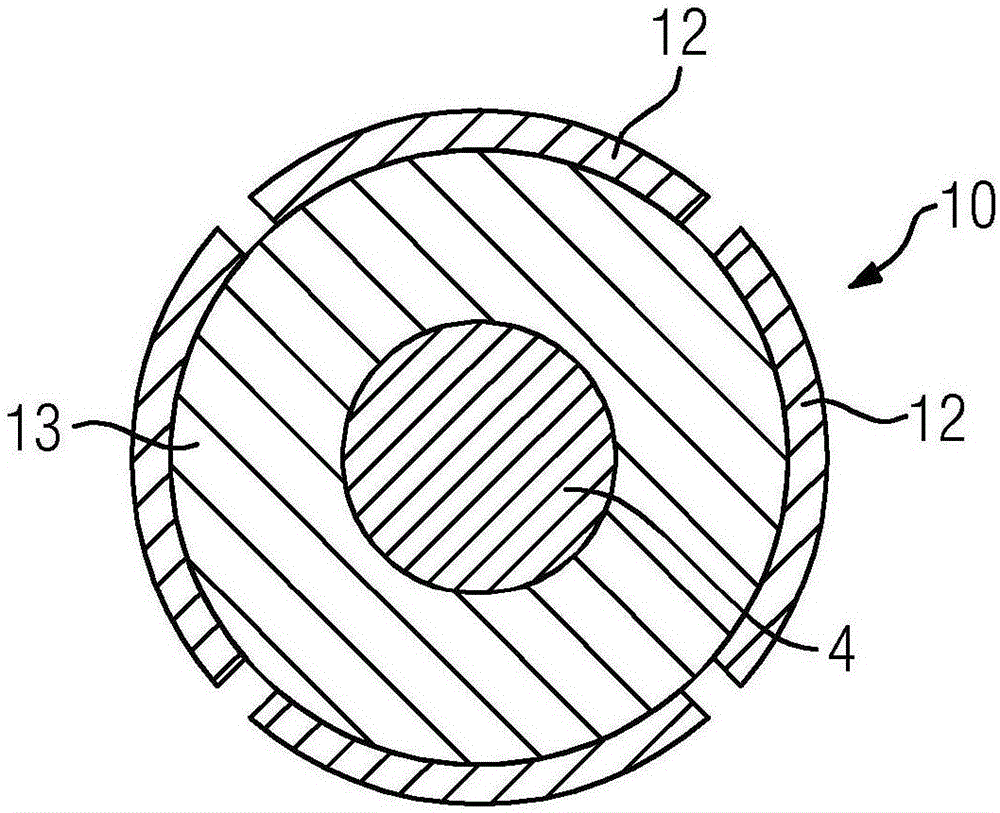

[0025] Figure 8 A reluctance motor with magnetic support is shown, in which an additional permanent magnet 12 is arranged in a flux lock 14 .

[0026] also, Figure 9 A known rotor type is shown in which each pole of the permanent magnets 12 forms a V-shaped arrangement and by means of this arrangement an additional reluctance support is obtained.

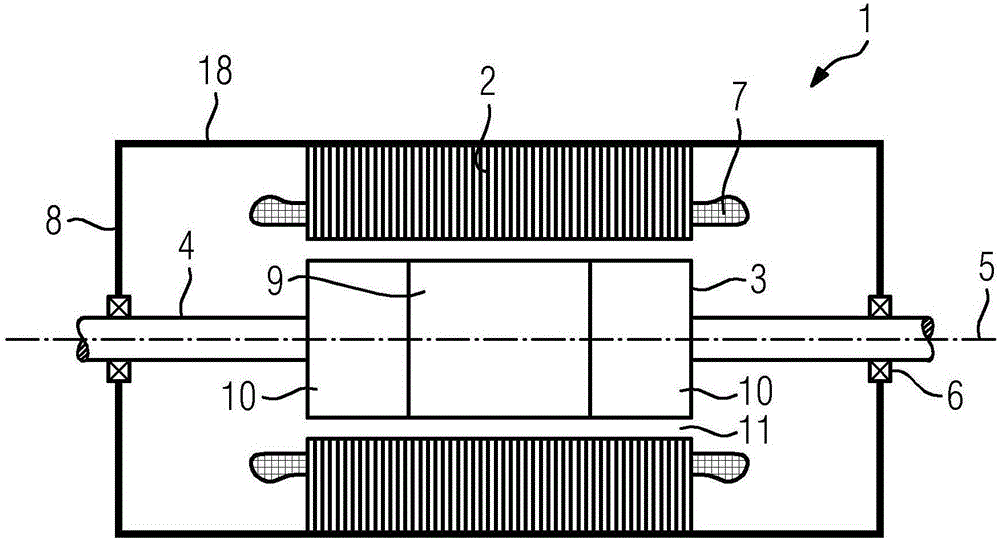

[0027] figure 1 A schematic diagram of an electromechanical machine 1 according to the invention is shown in longitudinal section with a stator 2 in which a winding system (not shown in detail) is arranged, which forms a winding head 7 on the front side of the stator 2 .

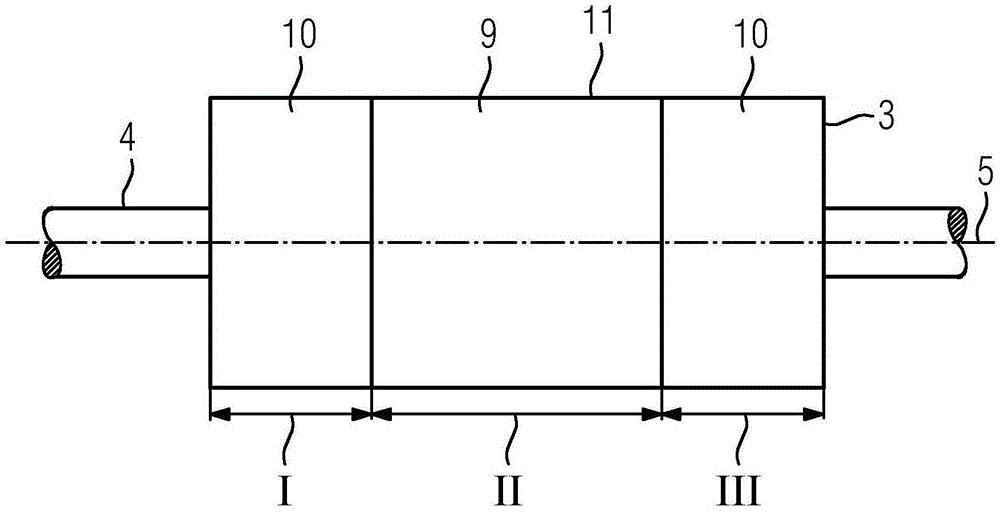

[0028] The stator 2 is arranged in a housing 18 . also, figure 1 A rotor 3 according to the invention is shown having three sections directly axially adjoining one another, which are positioned on a shaft 4 , wherein the shaft 4 is held by a bearing 6 and a corresponding end shield 8 .

[0029] In this case, the central section has a magneto-resistive lamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com