Fixing assembly for circuit board electroplating

A technology for fixing components and circuit boards. It is used in secondary processing of printed circuits, PCB positioning during processing, and non-metallic protective layers are applied. problems, to achieve the effect of simple structure, convenient operation, avoiding deformation or damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

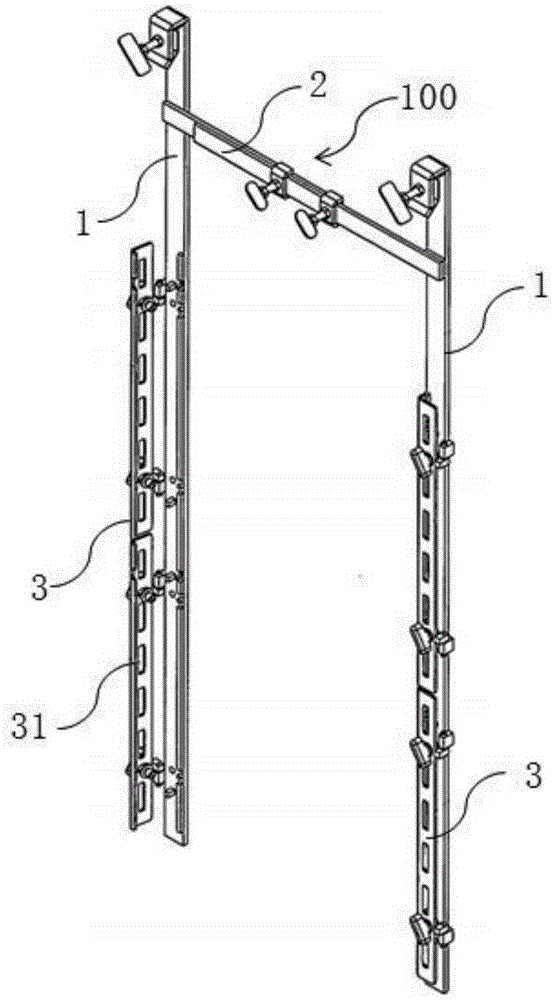

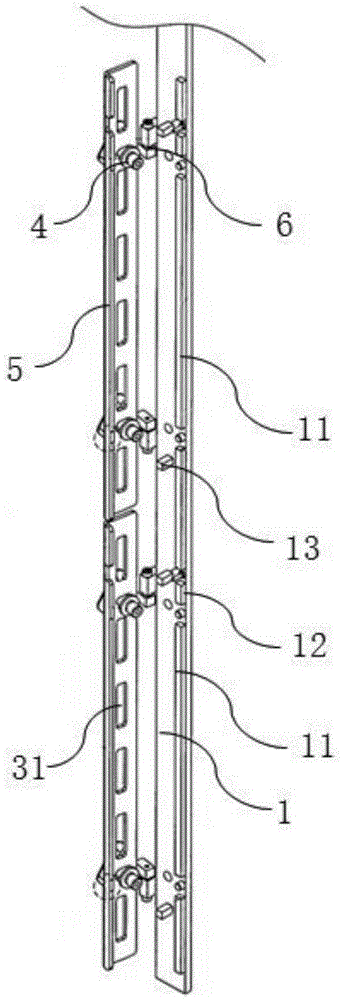

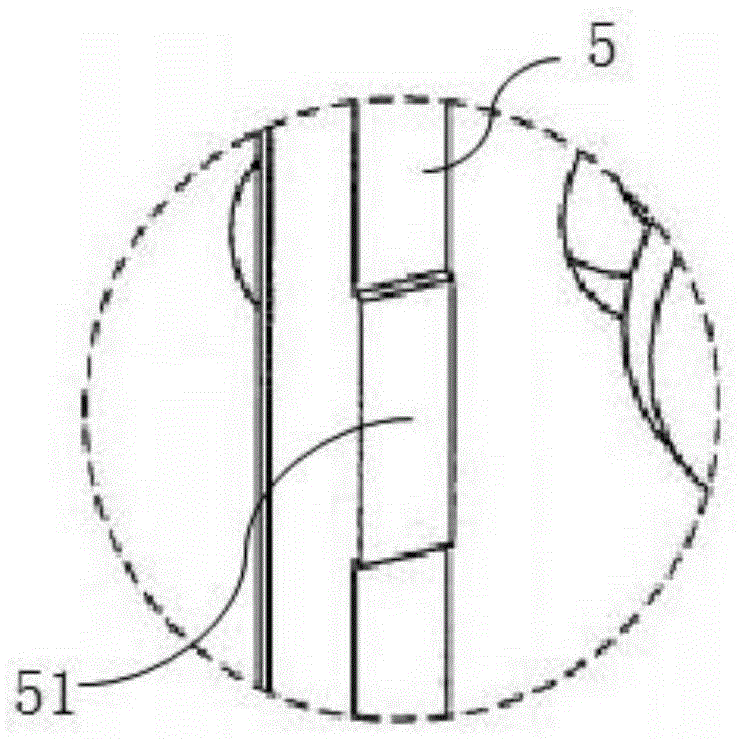

[0017] Such as Figure 1 to Figure 5 As shown, the fixing assembly 100 for circuit board electroplating of this embodiment includes a support rod 1 and a telescopic rod 2, the telescopic rod 2 is arranged between the support rods 1, and the telescopic rod 2 can adjust the distance between the support rods 1 . The fixing assembly 100 also includes a plurality of positioning plates 3 , and a locking assembly 4 is pierced on the surface of the positioning plates 3 . One side of the positioning plate 3 is provided with an extension plate 5 , and the other side is provided with a plurality of rotating shaft assemblies 6 , and the rotating shaft assemblies 6 are connected with the support rod 1 . The support rod 1 is provided with a protruding plate 11 and a conductive portion 12 , the protruding plate 11 is disposed opposite to the extension plate 5 , and the conductive p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com