A crawler garlic seeder based on hydraulic transmission

A technology of hydraulic transmission and seeder, applied in the direction of spaced quantitative sowing machinery, planting methods, applications, etc., can solve problems such as asynchrony and affect the sowing effect, improve passability, reduce labor intensity, and improve synchronization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

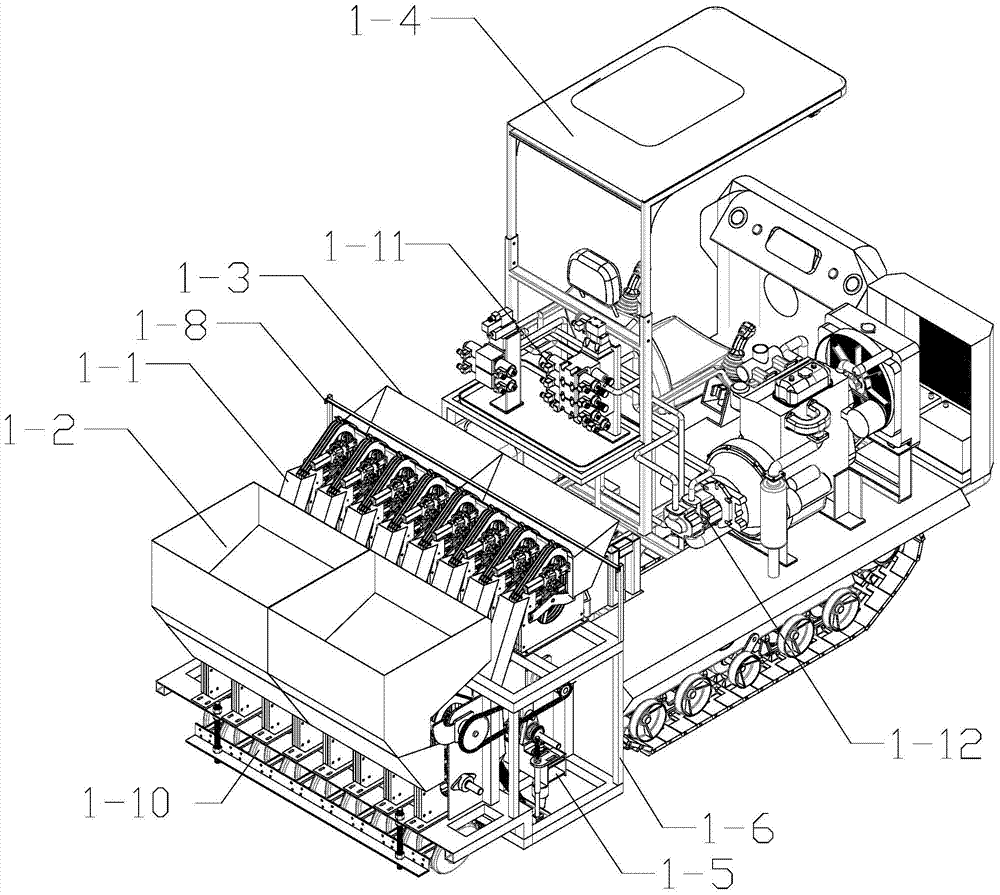

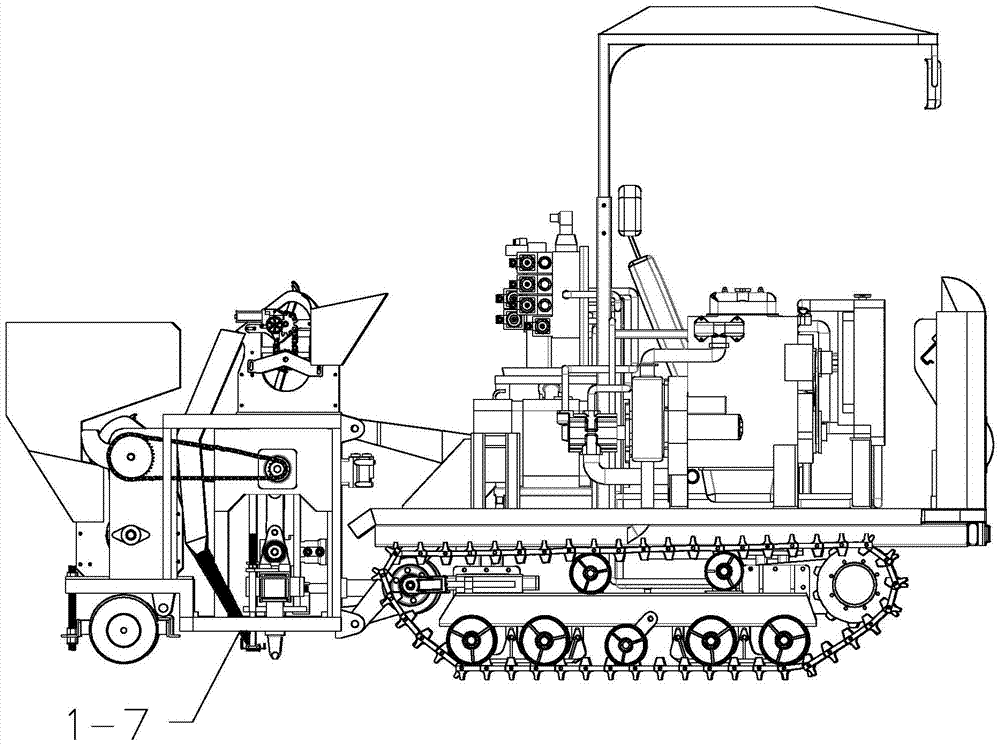

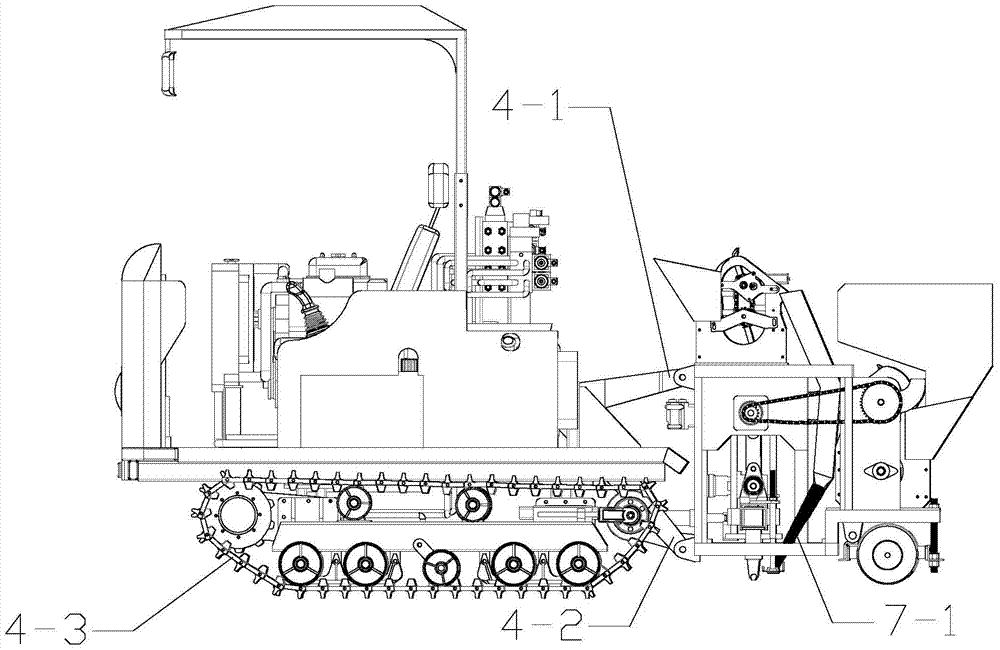

[0072] Embodiment: A kind of garlic seeder, its structure reference Figure 1-3 As shown, including the head 1-4, the head 1-4 rear end has a lifting arm 4-1 and a connecting arm 4-2, the two sides of the head 1-4 have crawlers 4-3, and the head 1-4 4 also has a hydraulic power source for driving the crawler belt 4-3;

[0073] The lifting arm 4-1 and the connecting arm 4-2 are hingedly connected to the same seeder 1-6 respectively through pin shafts, and the seeder 1-6 has a seeder frame;

[0074] The sowing mechanism 1-2 and the reseeding mechanism 1-3 are arranged on the seeder frame, and the rotating hole forming mechanism 1-5 is installed in the seeding machine frame, and the righting mechanism 1-7 is arranged behind the rotating hole forming mechanism 1-5 , the sowing mechanism 1-2 and the reseeding mechanism 1-3 are connected with the righting mechanism 1-7 through the inoculation slideway 1-1; There are seeding monitoring mechanisms 1-9, and the two monitoring mechani...

Embodiment 2

[0102] Embodiment 2: a kind of garlic seeder, refer to Figure 1-Figure 8 with Figure 11-Figure 20 As shown, the difference from Embodiment 1 is that the transmission of the cavitator is as follows Figure 21 shown. In the present embodiment, there are multiple cavitators 5-7, and all cavitators 5-7 are installed in the cavitator frame 5-5, and the ends of all cavitator 5-7 are equipped with Worm gear 5-12, all worm gears 5-12 are all meshed with same worm shaft 5-11, and worm shaft 5-11 is installed on the cavitator frame 5-5 or the sowing frame.

[0103] In this embodiment, the first hydraulic motor 6-1 can be installed horizontally or vertically.

[0104] When working, the second hydraulic motor 6-2 drives the worm shaft 5-11 to rotate through the helical gear, and the worm shaft 5-11 drives the worm gear 5-12 to rotate, so all the cavitators 5-7 rotate at the same speed. Rotation into holes has been realized.

Embodiment 3

[0105] Embodiment 3: a kind of garlic seeder, refer to Figure 1-Figure 8 with Figure 11-Figure 20 As shown, the difference from Embodiment 1 is that the transmission of the cavitator is as follows Figure 22 with Figure 23 shown. In the present embodiment, there are multiple cavitators 5-7, and all cavitators 5-7 are installed in the cavitator frame 5-5, and the ends of all cavitator 5-7 are equipped with Sprocket 5-14, two adjacent sprockets 5-14 are driven by same transmission chain 5-13, and transmission chain 5-13 is many. The second hydraulic motor 6-2 can be arranged vertically, which can drive one of the sprockets to rotate. When the sprocket rotates, it can drive all the transmission chains 5-13 to rotate, so all the cavitation devices 5-13 can rotate. 7 just rotate at the same speed. In other words, there is a sprocket wheel not equipped with drive chain 5-13 on the end cavitation device 5-5, and the sprocket wheel is engaged with the helical gear, and the hel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com