Straw crushing granulating machine cooperated with harvester and use method of same

A straw crushing and harvester technology, applied in harvesters, agricultural machinery and implements, applications, etc., can solve problems such as environmental pollution, and achieve the effects of solving environmental pollution problems, increasing fertility, and facilitating assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

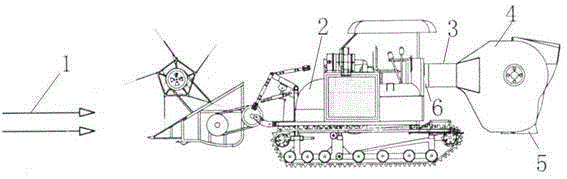

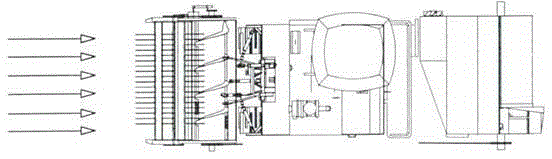

[0011] refer to figure 1 and figure 2 Among them, the present invention includes a crop 1 , a harvester 2 , a straw discharge port 6 , a feed port 3 , a straw crushing and granulator 4 , and a discharge port 5 . The stalk crushing granulator 4 is housed at the rear end of the harvester. The feed port 3 of the straw crushing granulator is connected with the straw discharge port 6 .

[0012] A method for using a straw crushing and granulating machine used in conjunction with a harvester, comprising: threshing the crops through the harvester, transporting the straw to the straw crushing and granulating device through the straw discharge port, and then crushing the straw into powder or granules shape, and sprinkle the field from the outlet to increase fertility and improve soil conditions. It can also be used for other purposes. Moreover, it is easy to assemble and disassemble, and can efficiently crush the straw discharged from the threshing chamber, ensuring that the straw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com