Isothermal forging forming method of high-temperature alloy complex sheet forging

A high-temperature alloy and isothermal forging technology, which is applied in the field of warm forging and forming, can solve the problems of difficult forming of forgings, easy folding of cross-section transitions, and insufficient filling of forgings, so as to improve the forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0022] The main chemical element content (percentage by weight) of the alloy is: C content≤0.08%, Cr content 17.0%~21.0%, Ni content 50.0%~55.0%, Co content≤1.0%, Mo content 2.80%~ 3.30%, Al content 0.30% ~ 0.70%, Ti content 0.75% ~ 1.15%, Nb content 4.75% ~ 5.50%, B content ≤ 0.006%, Mg content ≤ 0.01%, Mn content ≤ 0.35% , Si content ≤0.35%, P content ≤0.015%, S content ≤0.015%, Cu content ≤0.30%, Ca content ≤0.01%, Pb content ≤0.0005%, Se content ≤0.0003%, The balance is Fe.

[0023] The steps of this method are as follows:

[0024] Take a GH4169 alloy bar of a certain specification, put it into an electric furnace, heat it to 980°C, and keep it warm for 270min;

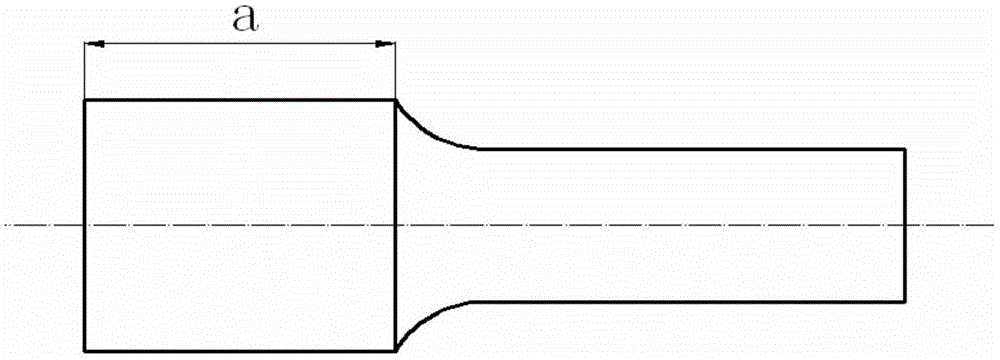

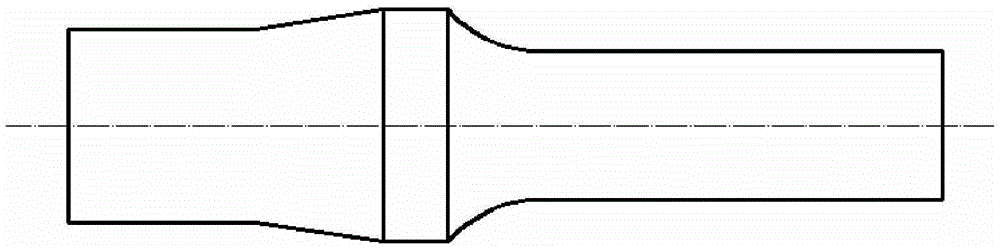

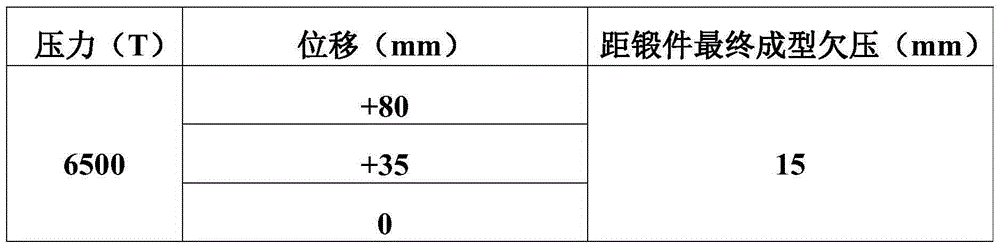

[0025] Take out the heat-preserved bar, upsetting on the free forging hammer, and then elongate; control the left end of the billet to remain unchanged, divide and elongate the distance a from the left end of the billet, and then upset the billet as a whole, as shown in 1 Show; then the left end of the blank is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com