U-type clamping claw self-centering rotary device

A rotary device, self-centering technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

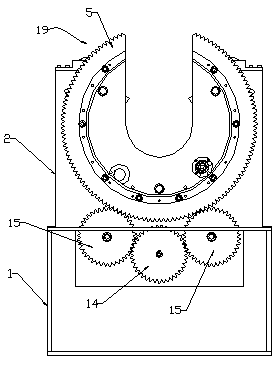

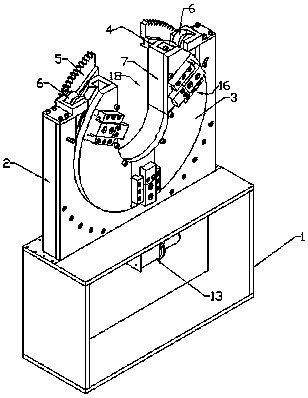

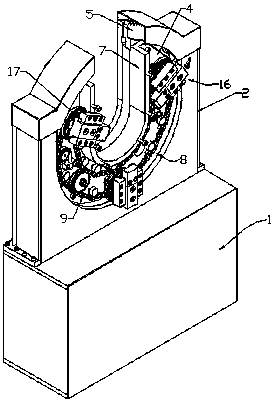

[0051] Examples such as Figure 1-Figure 13 As shown, the U-type clamping claw self-centering rotary device includes a base 1, and a support plate 2 is fixedly connected to the base 1. The support plate 2 has an opening, and a self-centering clamping mechanism 18 for tightening the workpiece is provided in the opening. .

[0052] The self-centering clamping mechanism 18 includes three clamping claws 16 , which are connected by a transmission mechanism 8 , and the three clamping claws can realize linkage under the action of the transmission mechanism 8 .

[0053] The self-centering clamping mechanism 18 also includes a turntable 4, three clamping claws 16 are evenly distributed around the center of the turntable 4, the angle between two adjacent clamping claws 16 is 120 degrees, and the transmission mechanism 8 can drive The three clamping claws 16 move synchronously towards the center of the turntable 4 .

[0054] The turntable 4 is provided with a U-shaped opening capable o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com