Assembly device of air suspension airbag assembly

An air suspension airbag and assembly assembly technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of slow leak test efficiency, low reliability, and low worker safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

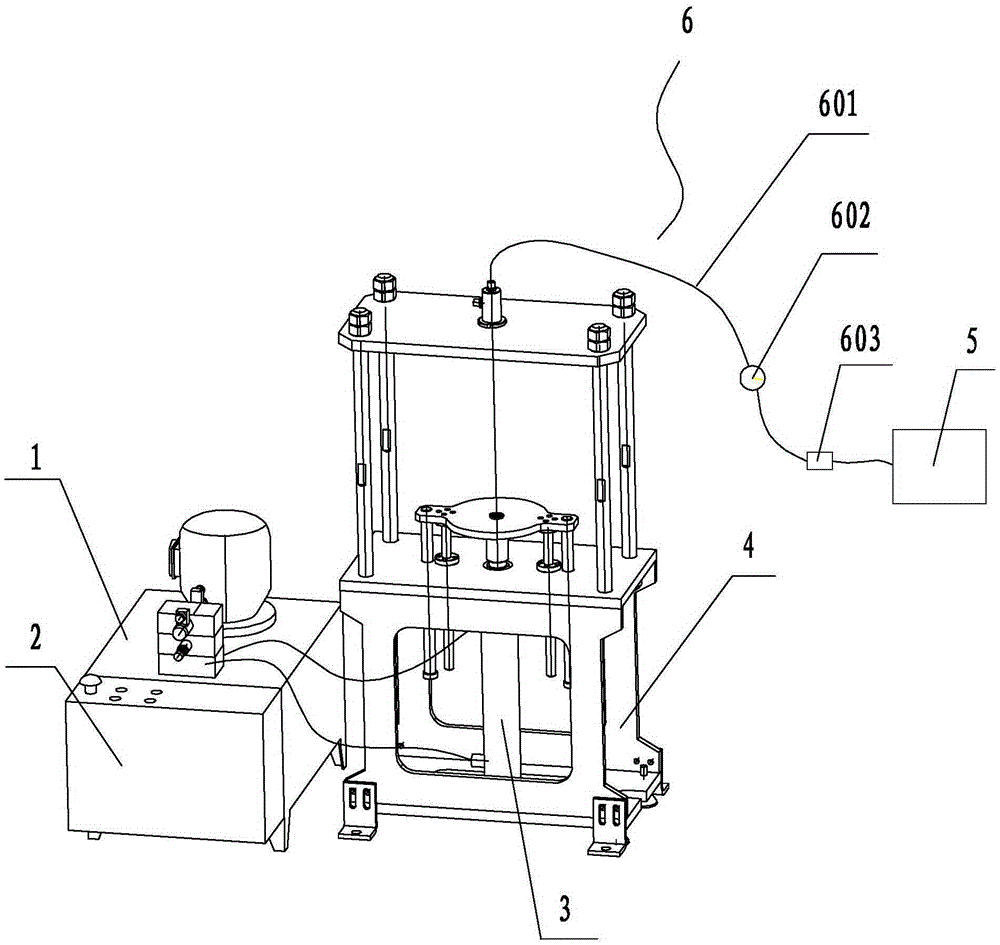

[0049] An air suspension airbag assembly assembly device, including a hydraulic station 1, an electric control box 2, an oil cylinder 3, an airbag assembly platform 4, and a compressed air source 5, wherein:

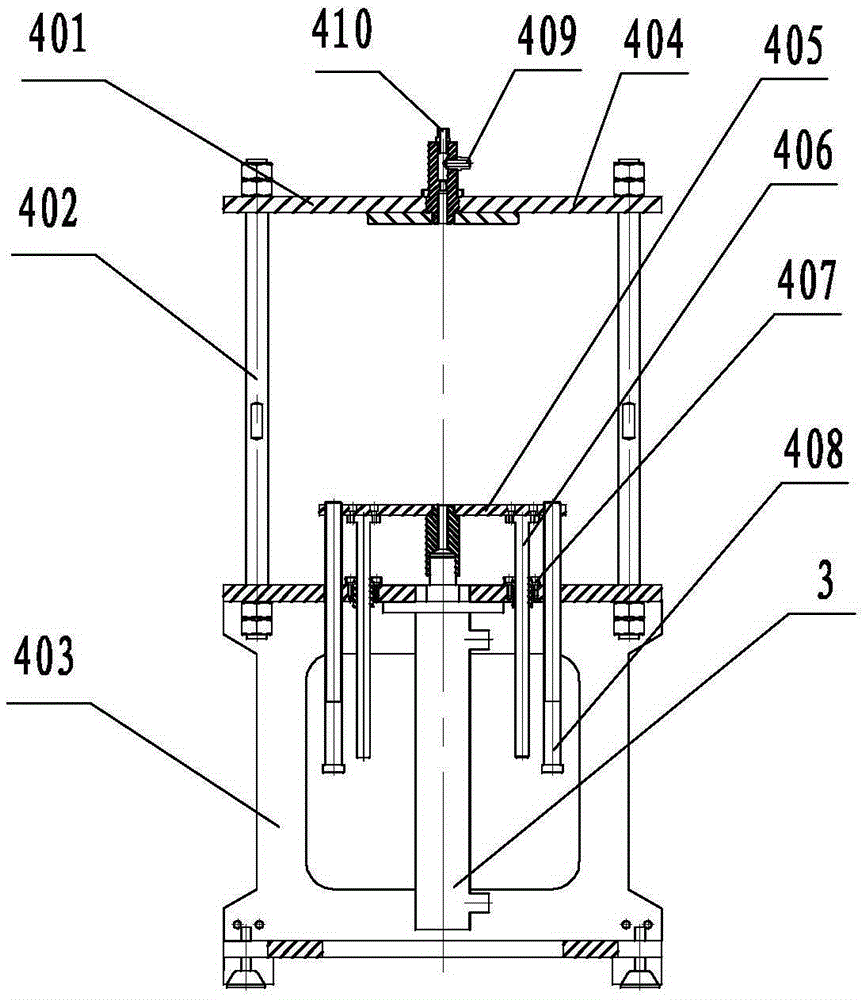

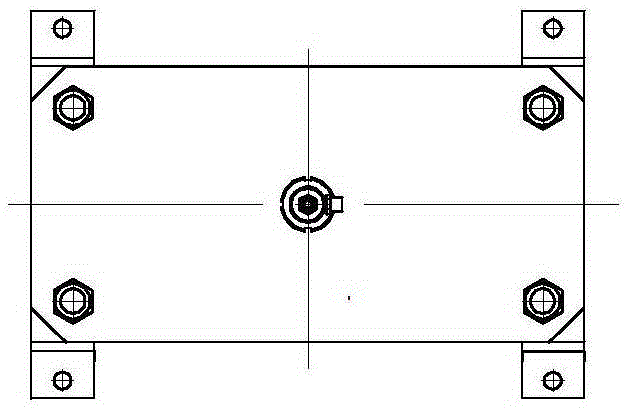

[0050] The airbag assembly platform includes a top plate 401, a base 403, an upper cover fixing assembly 404, and a lower seat fixing plate assembly 405. The top plate 401 and the base 403 are connected together by a support rod 402, and the upper cover The plate fixing assembly 404 includes an upper cover fixing plate 4041 and an air intake nozzle 4042, the upper cover fixing plate 4041 is installed on the bottom surface of the top plate 401, the bottom of the air inlet nozzle 4042 is connected on the upper cover fixing plate 4041, and the air inlet nozzle 4042 The top of the top protrudes from the top plate 401, and the air intake nozzle 4042 is provided with a through air intake passage 40421, and the air intake nozzle 4042 is also provided with a pressure relief valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com