Self-lifting on-wire device for hot-line work robot

A technology of self-elevating on-line and live work, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as robot conflicts, achieve flexible use, high efficiency, and reduce labor risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

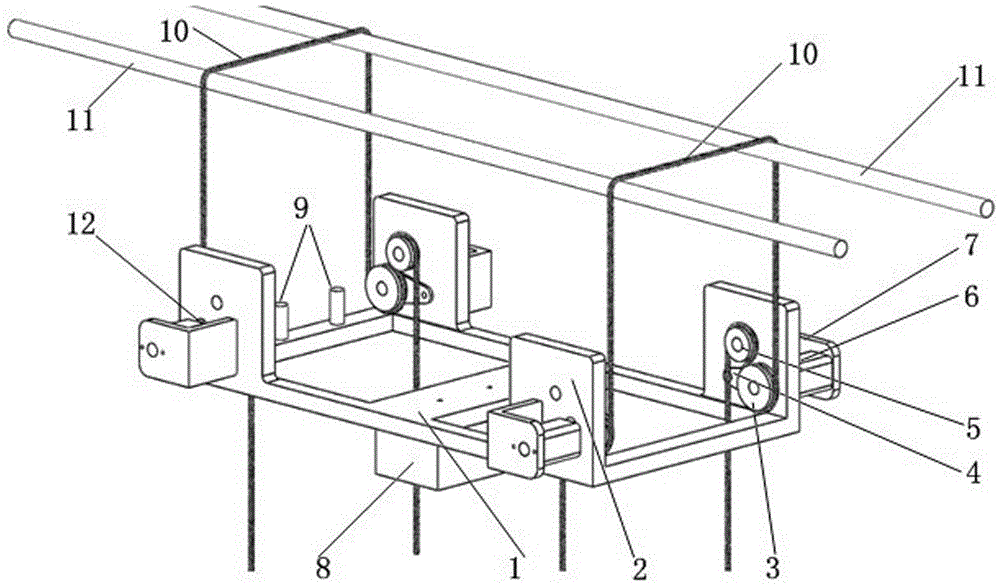

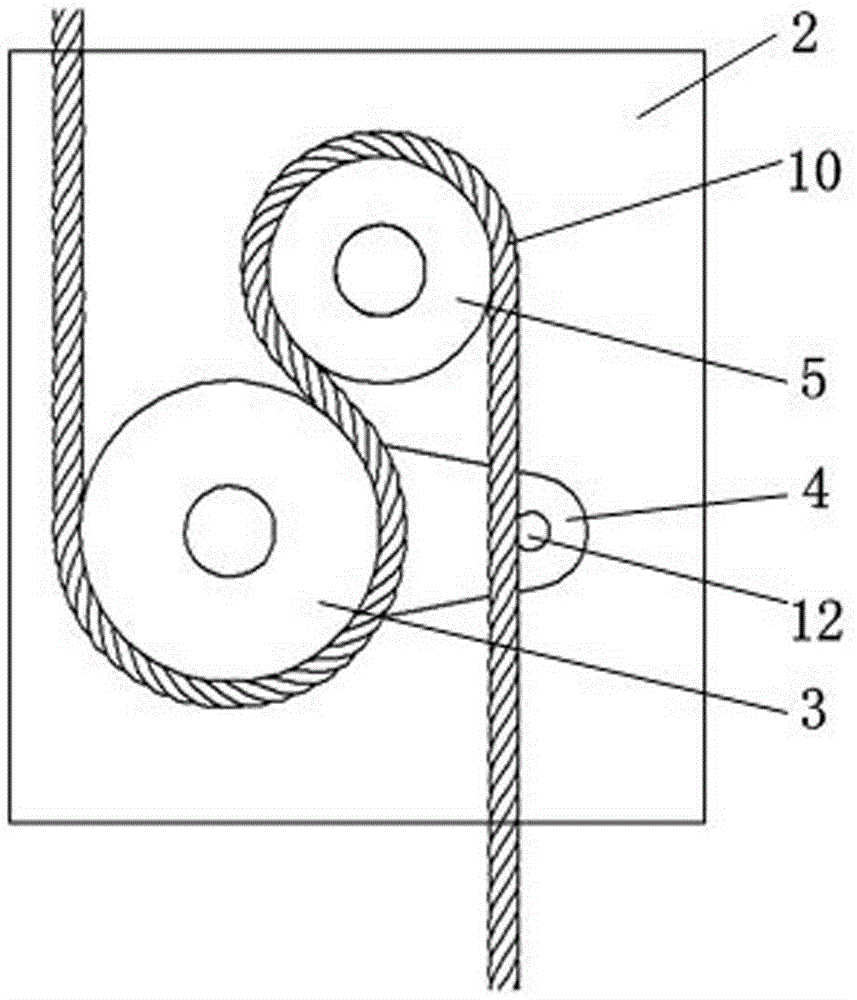

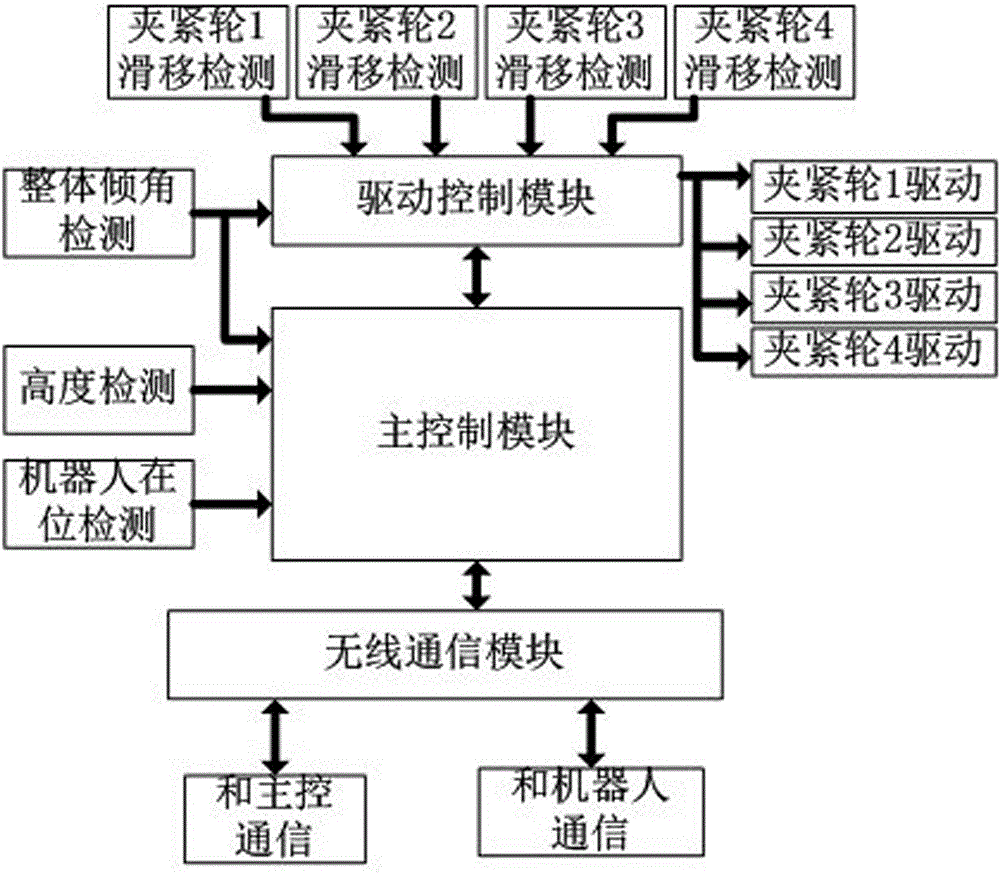

[0028] Such as figure 1 , figure 2 and image 3 As shown, the embodiment of the self-elevating on-line device of the live-working robot of the present invention is given. In this embodiment, the self-elevating on-line device of the live-working robot of the present invention consists of a load-carrying frame, a clamping wheel set, a motor and a control box.

[0029] The bearing frame 1 is a horizontal rectangular frame, and the two opposite frames are provided with vertical plates 2 near the two ends, which are used to install the clamping wheel set and the motor 6; on one of the other two frames, there are two vertical Cooperating with the positioning pin 9 for locking the robot, it is convenient for the robot to detect the in-position information and lock it with the carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com