Full-automatic filling equipment for hemodialysis concentrated liquid

A technology of hemodialysis and filling equipment, which is applied in the direction of liquid filling, barrel/barrel filling, etc., which can solve the problems of manual inability to check the liquid level from time to time, unstable control of filling volume, and inconvenient measurement adjustment, etc., and achieve structural Simple, convenient measurement and adjustment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

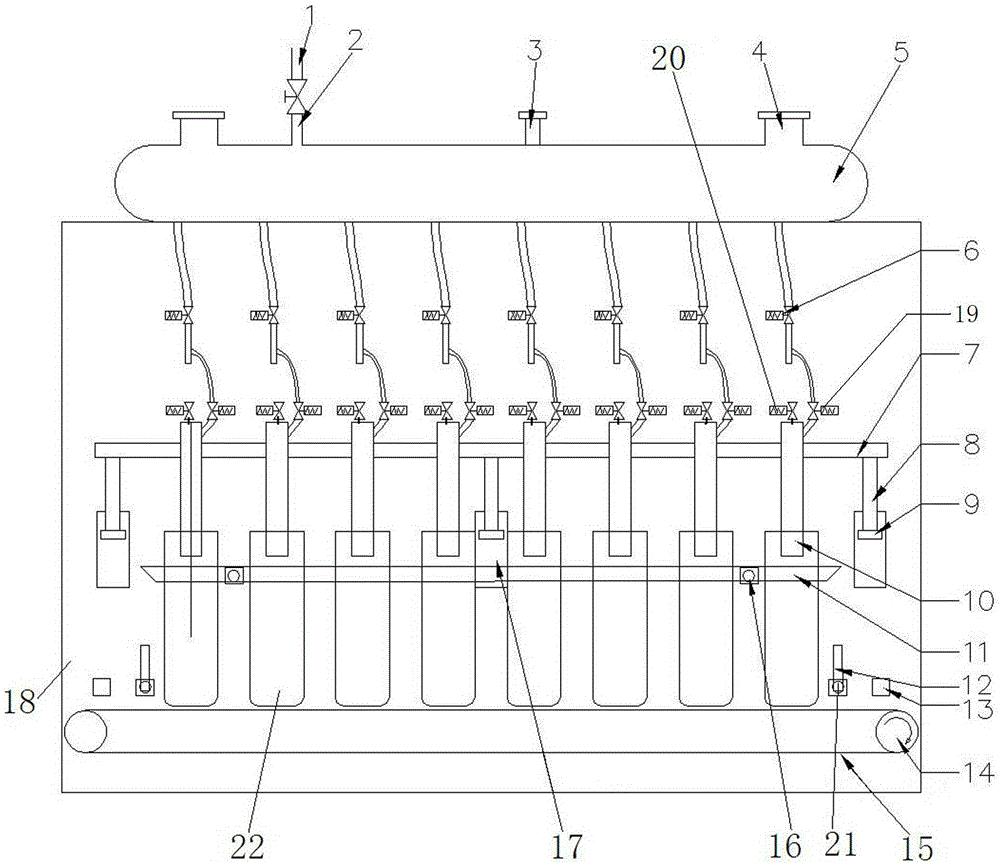

[0015] Refer to attached figure 1 , The fully automatic filling device for hemodialysis concentrate includes a chassis 18, a material box 5, a lifting frame 7, a lifting servo motor 17, a flow control valve 6, a leak stop valve 20, a filling head 10, a leak tank 11, and a leak tank Control cylinder 16, block knife cylinder 12, conveyor belt 15, conveyor belt transmission motor 14.

[0016] The material box 5 is installed on the top of the chassis 18, and the material box 5 is provided with a feed port 1, and the feeding is controlled by a pneumatic diaphragm valve 2. The top of the material box 5 is provided with a respirator 3 and a manhole 4, and the respirator 3 is equipped with a 0.22 The um hydrophobic polytetrafluoroethylene filter element filters the gas entering the material box 5 . There are multiple water outlets on the lower part of the material box 5, which are connected with a flow control valve 6. One end of the hose made of medical grade polytetrafluoroethylene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com