Repel oil from marine life pollution

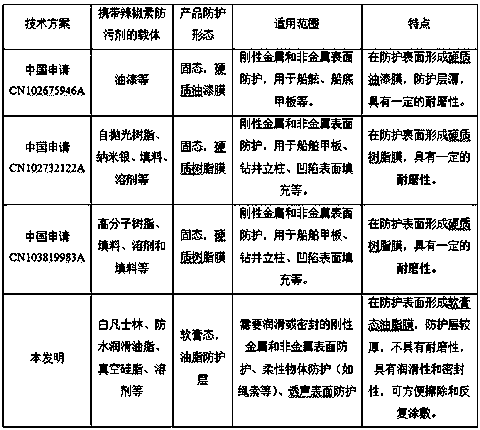

A technology of marine organisms and oils, which is applied to biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problems of large solvent consumption, complicated operation, and difficult release, and achieve prevention of growth and reproduction, concentration High, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] (1) Prepare materials according to the following components by weight percentage: 5% of high-concentration capsaicin oil, 95% of oily substances; the total capsaicin content in the high-concentration capsaicin oil is 78%, wherein capsaicin monomers account for the total capsaicin 73% of prime; Described grease substance is white vaseline;

[0026] (2) Heat the high-concentration capsaicin oil in step (1) until it melts, then add the melted high-concentration capsaicin oil to the oily substances, stir or homogenize or grind to achieve uniform mixing, and drive Grease polluted by marine life.

[0027] When the above-mentioned grease for repelling marine biological pollution is used, the grease for repelling marine biological pollution is coated on the outer surface of underwater equipment, and the thickness of the coating is 100-500 μm.

Embodiment 2

[0029] (1) Prepare materials according to the following components by weight percentage: 0.01% of high-concentration capsaicin oil and 99.99% of oily substances; the total capsaicin content in the high-concentration capsaicin oil is 70%, of which capsaicin monomers account for 70% of the prime; the oily substance is lubricating oil;

[0030] (2) Heat the high-concentration capsaicin oil in step (1) until it melts, then add the melted high-concentration capsaicin oil to the oily substances, stir or homogenize or grind to achieve uniform mixing, and drive Grease polluted by marine life.

[0031] When the above-mentioned grease for repelling marine biological pollution is used, the grease for repelling marine biological pollution is coated on the outer surface of underwater equipment, and the thickness of the coating is 100-500 μm.

Embodiment 3

[0033] (1) Prepare materials according to the following components by weight percentage: 8% of high-concentration capsaicin oil and 92% of oily substances; the total capsaicin content in the high-concentration capsaicin oil is 80%, wherein capsaicin monomers account for 80% of the total capsaicin 75% of the prime; the oily substance is a vacuum silicone grease;

[0034] (2) Heat the high-concentration capsaicin oil in step (1) until it melts, then add the melted high-concentration capsaicin oil to the oily substances, stir or homogenize or grind to achieve uniform mixing, and drive Grease polluted by marine life.

[0035] When the above-mentioned grease for repelling marine biological pollution is used, the grease for repelling marine biological pollution is coated on the outer surface of underwater equipment, and the thickness of the coating is 100-500 μm.

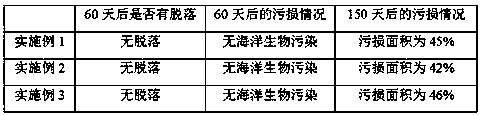

[0036] Each embodiment is coated on the outer surface of the underwater sample according to its use method, and the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com