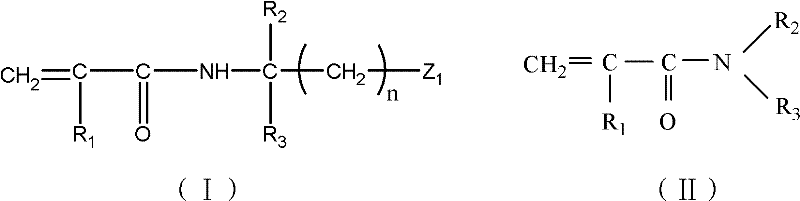

Method for preparing normal temperature-cured anti-fouling anti-drag hydrogel soft coating

A room temperature curing, soft coating technology, used in antifouling/underwater coatings, coatings, biocide-containing paints, etc. High problems, to achieve the effect of uniform distribution of cross-linking points, easy availability of raw materials and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Weigh 12.5g of 2-acrylamide-2-methylpropanesulfonic acid and dissolve it in 50ml of deionized water, add it to a four-neck flask, neutralize it under ice bath conditions, and adjust the pH to about 7 with a few drops of sodium hydroxide . Then weigh 4.2 g of 2-methyl-2-acrylic acid oxirane methyl ester and dissolve it in 50 ml of deionized water with 2.0 g of polyoxyethylene sorbitan monolaurate pre-emulsified and add it to four mouth flask. Under nitrogen protection, stir well for about 30 minutes. Then add 0.3g (NH 4 ) 2 S 2 o 8 and 0.2gNa 2 SO 3, Reacted at 35°C for 7h to obtain a crude product solution. Take 2ml of the crude product, add 0.007g of curing agent diethylenetriamine, stir for about 5 minutes, and then sonicate for 1 minute to remove air bubbles, then apply the above mixture evenly on the treated glass slide at room temperature and cure for 24 hours to form a film. The obtained film is about 1.1 mm in diameter, has a tensile strength of about 1....

Embodiment 2

[0035] Weigh 12.5g of 2-acrylamide-2-methylpropanesulfonic acid and dissolve it in 50ml of deionized water, add it to a four-neck flask, neutralize it under ice bath conditions, and adjust the pH to about 7 with a few drops of sodium hydroxide . Then weigh 0.8 g of 2-methyl-2-acrylic acid oxirane methyl ester and dissolve it in 50 ml of deionized water with 1.6 g of polyoxyethylene sorbitan monolaurate pre-emulsified and add it to four mouth flask. Under nitrogen protection, stir well for about 30 minutes. Then add pre-dissolved 0.2g K 2 S 2 o 8 and 0.14gNa 2 SO 3 , Reacted at 40°C for 7h to obtain a crude product solution. Take 2ml of the crude product, add 0.005g of curing agent diethylenetriamine, stir for about 5 minutes, and then sonicate for 1 minute to remove air bubbles, then apply the above mixture evenly on the treated glass slide and cure at room temperature for 24 hours to form a film. The thickness of the obtained film is about 0.9 mm, the tensile strength...

Embodiment 3

[0037] Weigh 4.0g of 2-acrylamide-2-methylpropanesulfonic acid and dissolve it in 50ml of deionized water, add it to a four-neck flask, neutralize it under ice bath conditions, and adjust the pH to about 7 with a few drops of sodium hydroxide . 0.5 g of 1,2-epoxy-7-octene was weighed and dissolved in 50 ml of deionized water pre-added with 1.4 g of polyoxyethylene sorbitan monolaurate and pre-emulsified, and then added to the four-neck flask. Under nitrogen protection, stir well for about 30 minutes. Then add 0.035g K 2 S 2 o 8 and 0.025g Na 2 SO 3 , Reacted at 40°C for 6h to obtain a crude product solution. Take 2ml of the crude product, add 0.003g of curing agent diethylenetriamine, stir for about 5 minutes, and then sonicate for 1 minute to remove air bubbles, then apply the above mixture evenly on the treated glass slide and cure at room temperature for 24 hours to form a film. The thickness of the obtained film is about 0.7 mm, the tensile strength is about 0.6 MPa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com